4-Axis Delta robot Setup

Contents

- 1 Introduction

- 2 Run softMC SIM

- 3 Run ControlStudio

- 4 Creating and Running a CONFIG.PRG file

- 5 Run Configurator Open new project

- 6 Create new Folder

- 7 Configuring Drive and Axes

- 8 Create Delta Robot

- 9 Build & Configure

- 10 Close Configurator

- 11 Create solution

- 12 Add watches

- 13 Run the Robot

- 14 Run Robot with roboDK

- 15 Robot Programs Example

Introduction

This example is still under construction

In this example we will use softMC simulator to create Delta Robot, run it from terminal watch some parameters and finally run it with roboDK

We select Delta robot from roboDK library, robot parameters:

Rbig = 110 [mm]

L1 = 100 [mm]

L2 = 270 [mm]

Rsmall = 40 [mm]

Gear 1:10

Typical velocity is 18,000/10 [deg/sec] 3000 [RPM]

Typical max velocity is 30,000/10 [deg/sec]

Typical Acceleration/Deceleration 720,000/10 [deg/sec]

Typical Max Acceleration/Deceleration 900,000/10 [deg/sec]

Typical Jerk is 2,160,000/10 [deg/sec]

Typical Jerk is 2,700,000/10 [deg/sec]

Note:

Tool value is: tool = #{0,0,15,0}

Run softMC SIM

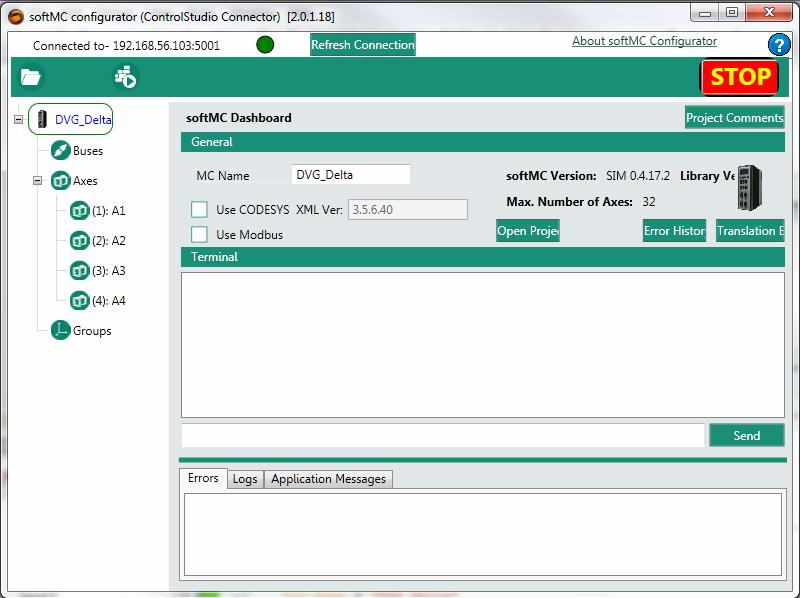

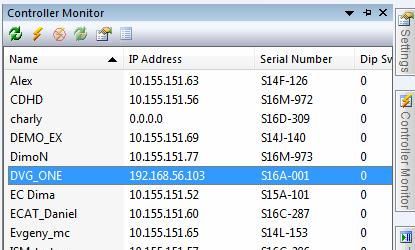

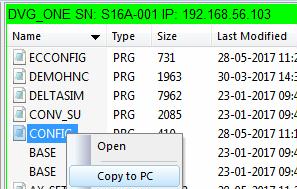

I run my softMC simulator with my VM, i login using mc for System login and Password than i type ifconfig to find my softMC simulator IP address, in the following example IP is 192.168.56.103

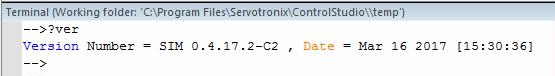

Run ControlStudio

Run ControlStudio and make sure you run the approporiate firmware version in following example we run Firmware 0.4.17.2-C2

Creating and Running a CONFIG.PRG file

The Configurator does not generate a CONFIG.PRG file, which is a necessary file.

The most simple CONFIG.PRG file will look like this:

Sys.NumberAxes = 4

program

Sys.Name = "DVG_Delta"

Print "system is running - " ; Sys.Name

Sys.DoubleFormat = 1 ; viewing the watch number

end program

NOTE: It is important that Sys.NumberAxes will be at least 4 as the Delta robot needs 4 axes.

Before opening the Configurator, make sure to run the CONFIG.PRG file by uploading it to the softMC using "Save and Load" and sending ">reset all" in the terminal.

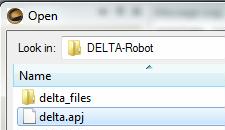

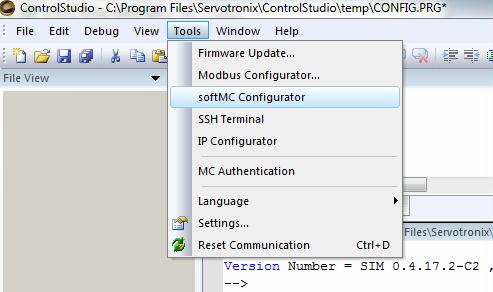

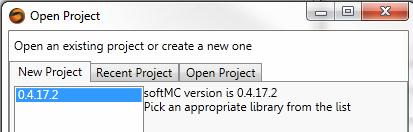

Run Configurator Open new project

Run configurator from ControlStudio and open new Project

Important Notes:

- You do not see any drive under Buses folder since you run in simulation

- Make sure you see 4 axis (A1 A2 A3 A4)

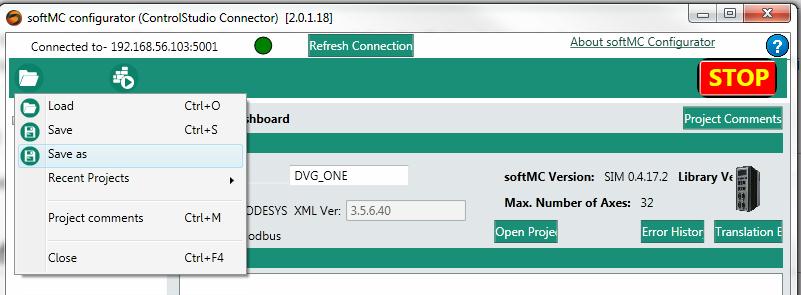

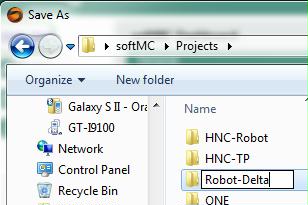

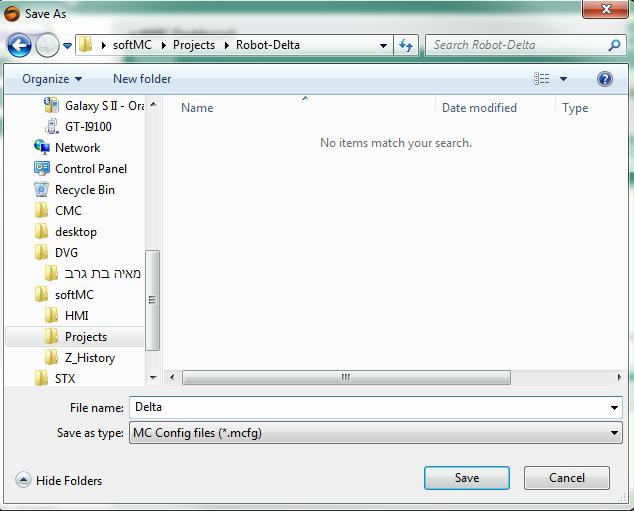

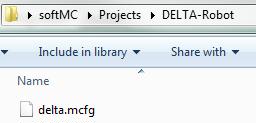

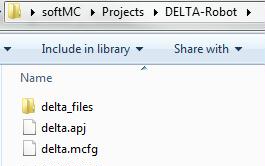

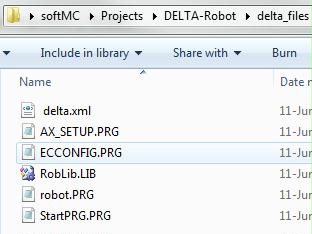

Create new Folder

Now we will create our folder and our configuration file, to do it we will use "Save As" create "New" folder and name our configurator file as Delta

Configuring Drive and Axes

Define Drives

Since we work with softMC simulation we do not have any drives and can skip to the next one

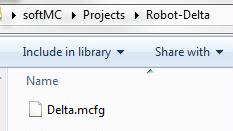

Define Axes

Press on the first axis and its configuration window will show:

- Choose the "Axis Type". Please choose: "Rotary Gear" for the Delta robot.

- Set the Gear Ratio value to the correct value. we will keep value 1

Repeat the last steps for each used axis.

Hint:

If you have similar axis you can do all the setting than copy entire axis with right mouse clicking on the axis

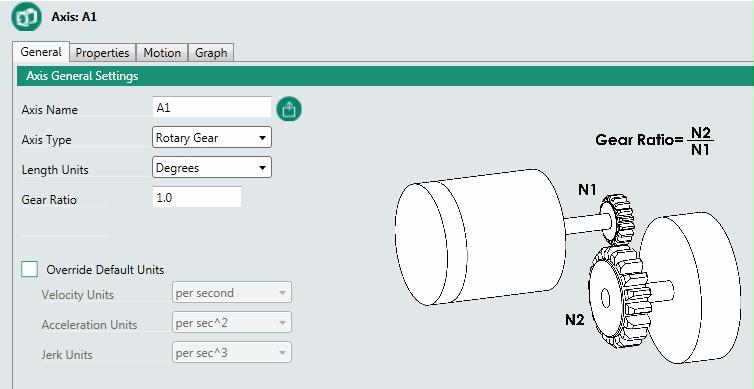

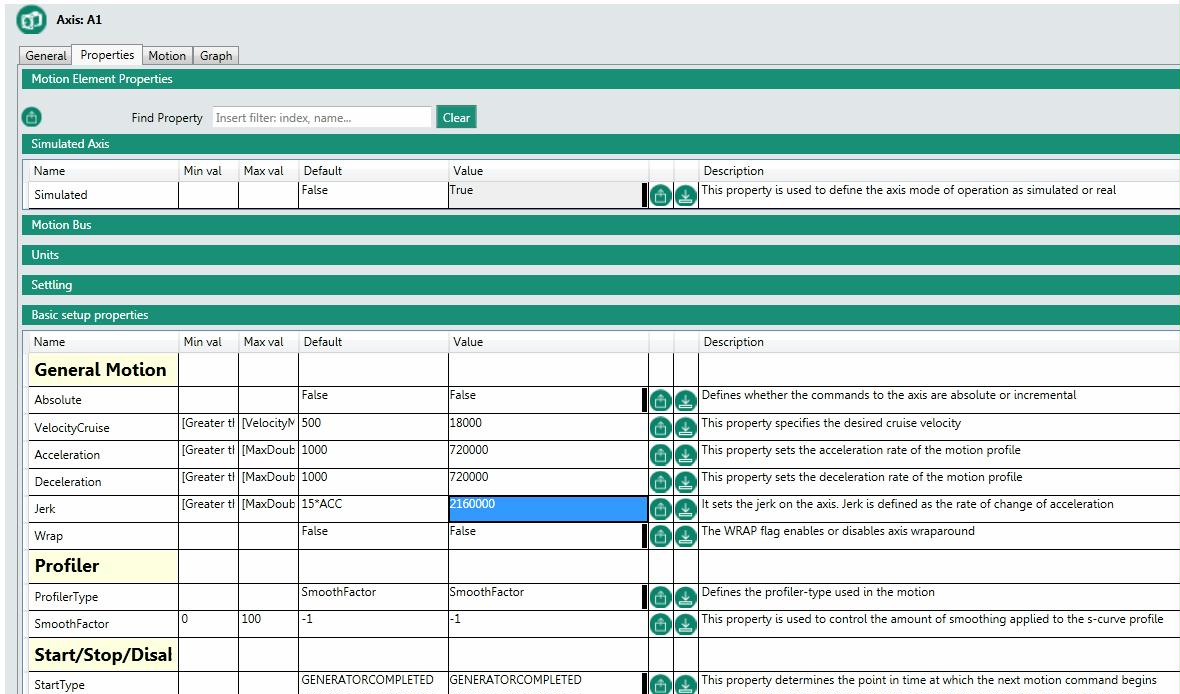

The configuration window of the axes has few tabs.The "Properties" tab allows to set the axis properties. Set following properties appropriately to each axis

Important: this value are the final value after the gear

for a simulated robot, change the "Simulated Axis" property to "True"

velocity is 18,000 [deg/sec] 3000 [RPM]

max velocity is 30,000 [deg/sec]

Acceleration/Deceleration 720,000 [deg/sec]

Max Acceleration/Deceleration 900,000 [deg/sec]

Jerk is 2,160,000 [deg/sec]

max Jerk is 2,700,000 [deg/sec]

Position error max 10

Create Delta Robot

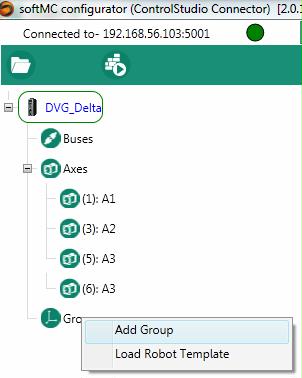

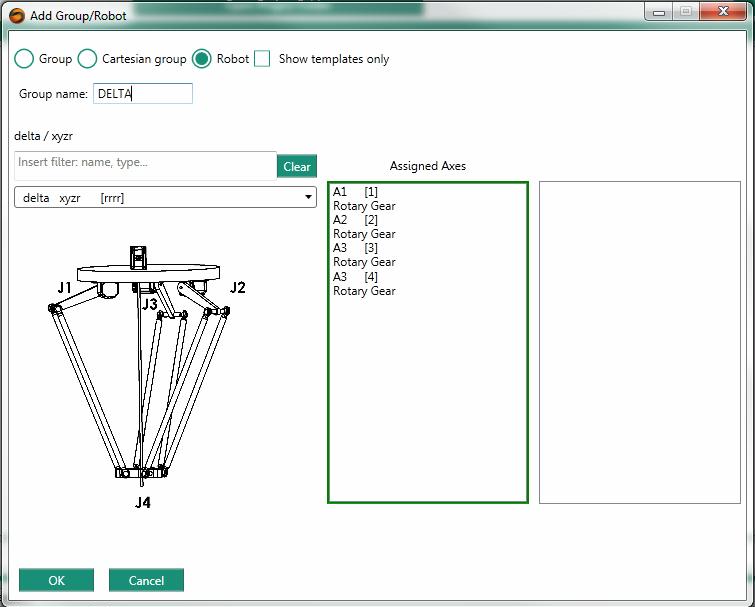

Right clik on Group icon and select Add Group

Select Robot

Group name DELTA

Select delta xyzr [rrrr]

Click on all four axis, note the frame color change from red to green

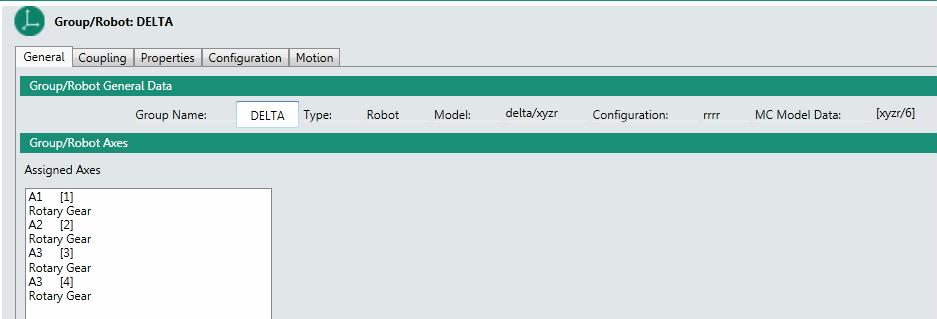

General

This tab allows to switch the axes which are linked to the group and to change the axes properties in cause you have more than 4 axis

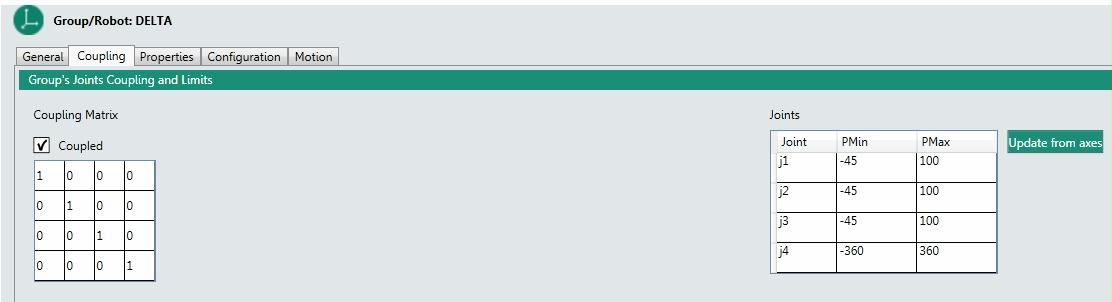

Coupling

- Coupling matrix shouldn't be changed for a delta robot (define if Motor axis rotate only specific joint or more than one joint)

- Each joints position limits per axis.

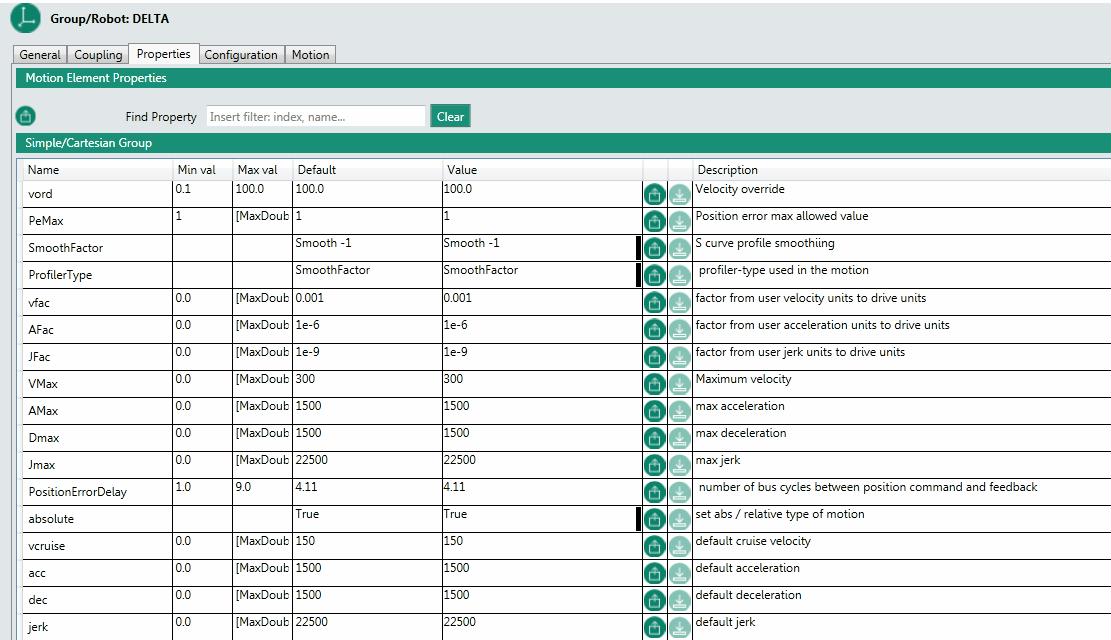

Properties

This tab allows to set the robot properties, such as: position limits, speed limits, acceleration limits, etc.

Note:

- Make sure to set Position error max to 10 in simple/Cartesian table "PeMax" (-->delta.pemax=10)

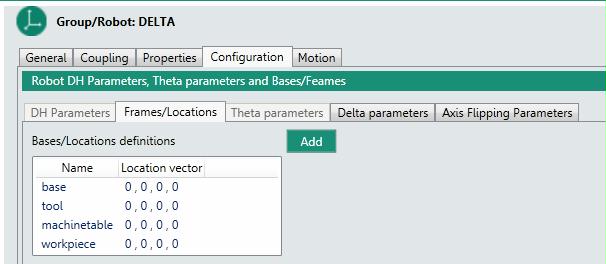

Configuration

This tab has 3 sub-tabs:

- Make sure to set Tool Z axis to 15 to accomodate w RoboDK (-->delta.tool=#{0,0,15,0} )

For more information use the link

base

tool

machinetable

workpiece

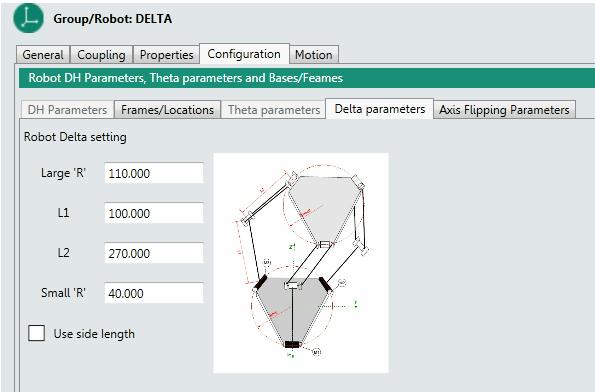

Delta parameters

Here we set the Delta robot mechnical parameters:

Rbig = 110 [mm]

L1 = 100 [mm]

L2 = 270 [mm]

Rsmall = 40 [mm]

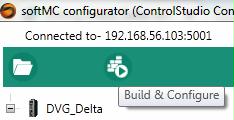

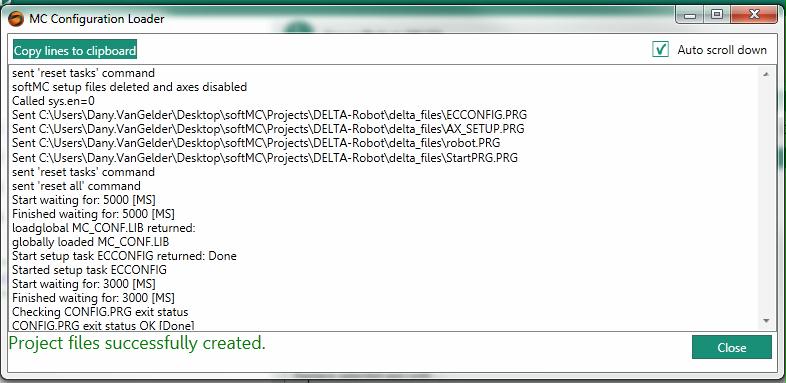

Build & Configure

Now we are ready to generate setup and communication files and run them on the softMC, click on "Build & Configure"

|

---> |

|

| Before Build & Configure | After Build & Configure |

|---|---|

|

|

| |

|

Close Configurator

Now exit the configurator we can go back to configurator later on

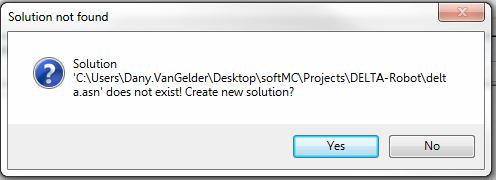

Create solution

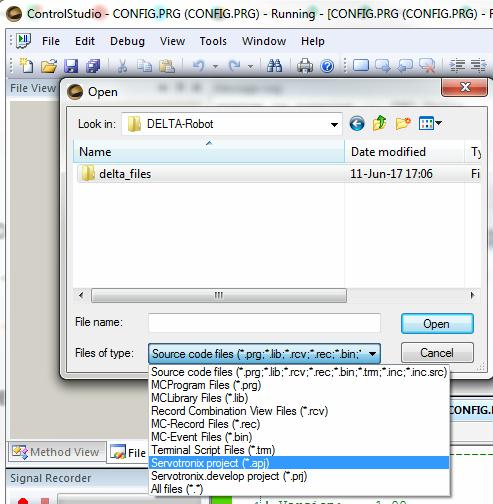

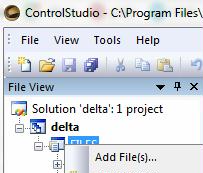

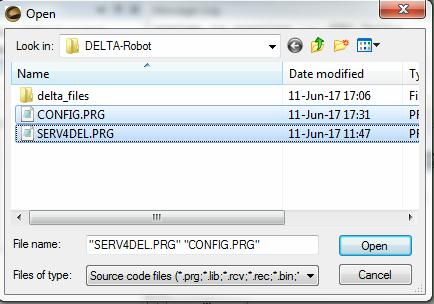

To create solution we have to do the following:

- Open Project (apj file) created by Build & Configure

- Save it as Solution (asn file)

- Add Config.prg from the Controller to PC

- Copy any user previews programs to the folders using explorer

- Add File(s) to the Solution tree

Add Config.prg from the Controller to PC

Add File(s) to the Solution tree

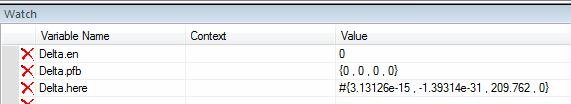

Add watches

Lets look what we have from Terminal

-->?grouplist

DELTA:A1,A2,A3,A4

and Add Delta watch for Enable Position feedback and XYZR value

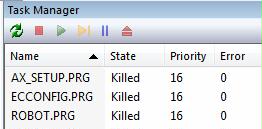

Run the Robot

Run Robot now

Now we can run the robot

-->Delta.en=1

-->move delta {0,0,0,20}

Run Robot after re cycle

Do the following:

- Run and start the softMCSIM

- Run ControlStudio and connect to your softMCSIM

- Open your Solution "Delta"

- Double click on Program file "StartPRG.PRG"

- Click on the Icon "Save and Load"

Robot Delta is ready

Run Robot with roboDK

Open TCP/IP server to work with RoboDK

Save Load and run SERV4DEL.PRG, Than make sure you see "socket 2 is set" in ControlStudio Message log

Tip: use windows key + left error to get ControlStudio on the half left windows

' Version: 1.00

' Author: Ron Danon DVG

' Description:

' History: 2017-06-17 base on server.prg V1.00

' Created

'------------------------------------------------------------------------------

dim shared numOfRobots as long = 1

program continue

dim index as long

dim sockNum as long = 2

dim cPort as long = 7132

dim jointStr as string

dim robotGroups[1] as generic group 'same as size of numOfRobots

dim robotNames[1] as string 'same as size of numOfRobots

'---------------Define robot groups and names---------------'

robotGroups[1] = DELTA

robotNames[1] = "robot1"

'robotGroups[2] = PUMA2

'robotNames[2] = robot2

'---------------Opening new socket---------------'

call openNewSocket(sockNum,cPort)

'---------------Connecting to client---------------'

call connectClient(sockNum,cPort,0)

'---------------Main Loop---------------'

while True

call createJsonStr(robotNames,robotGroups,jointStr)

call checkIfReady(sockNum,cPort)

' ?jointStr

' ?SIZE(jointStr)

print #sockNum,jointStr

end while

'---------------Close sockets and exit---------------'

print #sockNum,"finish"

sleep 1000

close #sockNum

Print "Server Closed Sockets. Server Exits"

end program ' server.prg

'---------------------------------------'

'---------------Functions---------------'

'---------------------------------------'

sub openNewSocket(sockNum as long,cPort as Long)

dim opened as long = 0

while not opened

Try

OpenSocket Options=1 as #sockNum

opened = 1

catch 5043 'socket is already open

print "socket", sockNum, "is already open. trying next socket"

sockNum = sockNum + 1

end Try

end while

print "socket", sockNum, "is set"

end sub

sub connectClient(sockNum as long, cPort as Long, ByVal sockIsOpen as long)

dim str1 as string

if sockIsOpen then

close #sockNum

OpenSocket Options=1 as #sockNum

end if

Accept(#sockNum, cPort)

sleep 500

str1=input$(loc(sockNum),#sockNum) 'receive data to check if connected

?"client is connected"

sleep 200

end sub

sub checkIfReady(sockNum as long,cPort as Long)

'Waits for a 'ready' input from roboDK before sending the next JSON string

dim ready as long = 0

while not ready

Try

while loc(sockNum) = 0 'while no data is available

sleep 10

end while

catch 5041 'client disconnected

print "client disconnected, waiting for connection"

call connectClient(sockNum,cPort,1)

end Try

ready = (input$(loc(sockNum),#sockNum) = "ready") 'check if the input is "ready"

end while

end sub

sub createJsonStr(robotNames[*] as string, robotGroups[*] as generic group, jointStr as string)

'FORMAT --> '{"robotName": [double-a1, double-a2, double-a3, double-a4, double-a5, double-a6]}' <---

'double is in precision of 2 digits after the point, i.e.: '0.12', '179.12'

dim index1 as long

dim index2 as long

dim jointValues as generic joint

dim temp as long = 50

jointStr = "{"

for index1 = 1 to numOfRobots

jointValues = robotGroups[index1].PFb

jointStr = jointStr + chr$(34) + robotNames[index1] + chr$(34) + ": ["

for index2 = 1 to robotGroups[index1].ElementSize

if index2 = 4 then

temp = 0

else

temp = 50

end if

jointStr = jointStr + STRD$(-jointValues{index2} + temp, "%.2f") + ", "

next

jointStr = LEFT$(jointStr,LEN(jointStr)-2) + "], "

next

jointStr = LEFT$(jointStr,LEN(jointStr)-2) + "}"

end sub

'---------------End of functions---------------'

Run RoboDK

Copy paste to your folder "Fanuc_Delta.rdk" prepared by Servotronix include

- Delta robot from RoboDK library

- Prog1 a pyton script which open TCP/IP socekt to work with softMCSIM / serv4del.prg

Double click on the Prog1 icon and make sure you see in ControlStudio Message TBD

Prog1

import mcEnv

#host, port = "192.168.56.103", 7132

host, port = "10.4.20.59", 7132

finsihedTransmit = False

MCE = mcEnv.MCenv()

MCE.setSimulationSpeed(1000)

MCE.connectClient(host,port)

MCE.setRobot("robot1", "Fanuc M-1iA/0.5S")

robotList = ["robot1"]

while not finsihedTransmit:

MCE.writeStr("ready")

jsonStr = MCE.readJsonStr()

MCE.moveRobots(robotList, jsonStr)

raise Exception('Finished')

Robot Programs Example

Here is a simple Pick and place program which you can watch in the RoboDK simulation

'------------------------------------------------------------------------------

' File: PnPTDelta.prg

' Purpose: Robot Pick & Place

' Version: 1.00

' Author: DVG

' History: 17.Jun.2017 - created

'------------------------------------------------------------------------------

' module global "constants"

' module global variables

dim shared ZeroPosition as joint of xyzr = {0 , 0 , 0 , 0 } 'Moving as joint - for initial positioning

dim shared P1Position as joint of xyzr = {0,0,0,10} '{J1,J2,J3,J4}

dim shared P1 as location of xyzr = #{0 , 0 , 0 , 20 } '{X,Y,Z,R}

dim shared P11 as location of xyzr = #{0 , 0, 0 , 40}

dim shared P22 as location of xyzr = #{0 , 0, 0 , 60}

dim shared P2 as location of xyzr = #{0 , 0, 0 , 80}

dim shared RobotVelocity as double = 40.0

program

with Delta 'set default group element, no need to explicitly indicate the motion element

Attach 'Attach the task to motion element (with Delta)

En = TRUE

Sleep 100

Vcruise = RobotVelocity 'Set robot's cruise velocity

while NOT En

Sleep 100

end while

Move ZeroPosition 'moving to zero position

WaitForMotion Delta

call pickPlaceXYZ 'execute Pick and Place function

Move ZeroPosition

WaitForMotion Delta

Detach

end with

end program

sub pickPlaceXYZ

dim i as long

Move Delta P1Position

WaitForMotion Delta

Delta.BlendingMethod = 2 'Type of motion blending - 2 is SuperPosition blending - in order to optimize movement, so that it will be as fast as possible

Delta.BlendingFactor = 80 'Percentage of the movement’s length that will not be blended with the next movement

Delta.Cp = 10 'At continous path blednign, sets the blend radious value - bigger equal smoother

for i = 1 to 10

Moves Delta P11

WaitForMotion Delta

Moves Delta P1

WaitForMotion Delta

Moves Delta P11

WaitForMotion Delta

Moves Delta P22

WaitForMotion Delta

Moves Delta P2

WaitForMotion Delta

Moves Delta P22

WaitForMotion Delta

next i

Move Delta ZeroPosition

WaitForMotion Delta

end sub