Teach Pendant Installation Guide

Contents

Product Overview

The softTP teach pendant (TP) is an add-on tool for softMC-based systems. It allows users to move the robot by means of jog keys, and to create and run complete robot programs written in MC-Basic.

The softTP touch screen interface enables quick and easy application development.

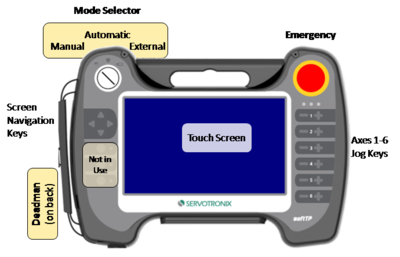

Teach Pendant Hardware

- Touch screen

- Jog buttons

- Emergency switch

- Deadman switch

- Mode Selector switch

- Jig board for power, Ethernet communication and digital outputs

Teach Pendant Software

The following software components are provided with the softTP:

- Java Runtime Engine

- Java Web Server (HTML to KMAPI converter) and WWW folder (HTML files and Java scripts)

- softTP license (MCTP file)

- softTP programs and libraries (MC-Basic source code)

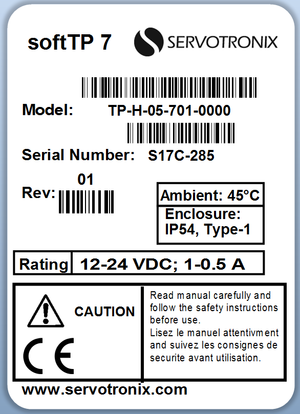

Product Label

Safety

Warnings

Handling and Maintenance

- Make sure cabling is secure and cannot be tripped over.

- Make sure cabling is not bent or crushed by other objects.

- Make sure cabling does not come into contact with sharp edges that can cause it to fray.

- Make sure the softTP is never set down in a manner in which operating elements may be mechanically damaged.

- Never place the softTP where it will be subject to high heat sources or direct sunlight.

- Avoid subjecting the softTP to mechanical shocks, excessive dust, humidity or strong magnetic fields.

- Do not use solvents or abrasive materials on the softTP. For cleaning use a soft cloth moistened with water or a mild cleaning agent.

- The softTP has a touch screen. Use only your finger to operate. Make sure no sharp objects come into contact with the screen.

Specifications

Technical Specifications

| Item | Specification |

|---|---|

| Processor | Intel®Atom™E3800/1.6 GHz single core |

| Memory | DDR3 4 GB |

| NAND | SSD 32 GB |

| Rating | 12-24 VDC, 1-0.5 A |

| LCD Screen | TFT LCD. 7-inch (163 x 104 mm). Resolution 800x480 pixel. Background lighting 24 LEDs. |

| Touch Screen | 4-wire analog-resistive. USB touch controller. |

| OS | Lubunto |

| LEDs | 3-color LED x 6 |

| SD/MMC | External SD card |

| USB | USB host |

| Keypad | -) keys. 4 screen navigation keys. 4 function keys (not used). |

| Switches | Emergency/Mode Select/Deadman |

| Communication | RS232/RS485/Ethernet. Selectable |

| Operating Temperature | 45°C max. ambient |

| Enclosure | IP54 |

| Compliance | CE |

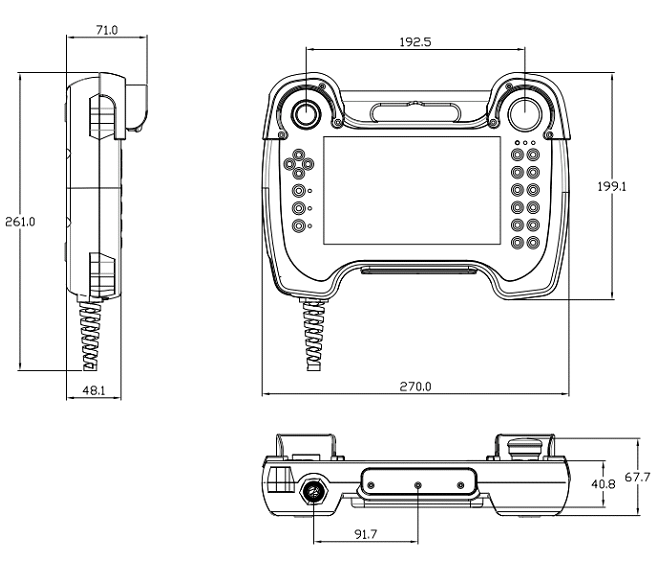

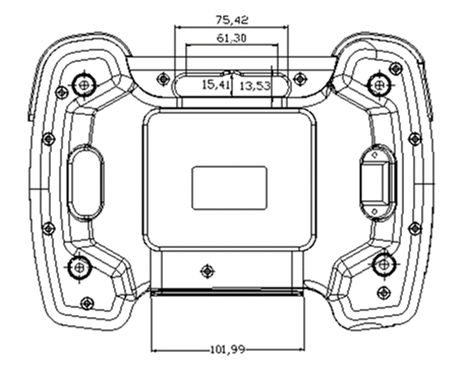

Dimensions

Wiring

Teach Pendant Cable

The teach pendant cable is part of the softTP; it cannot be detached.

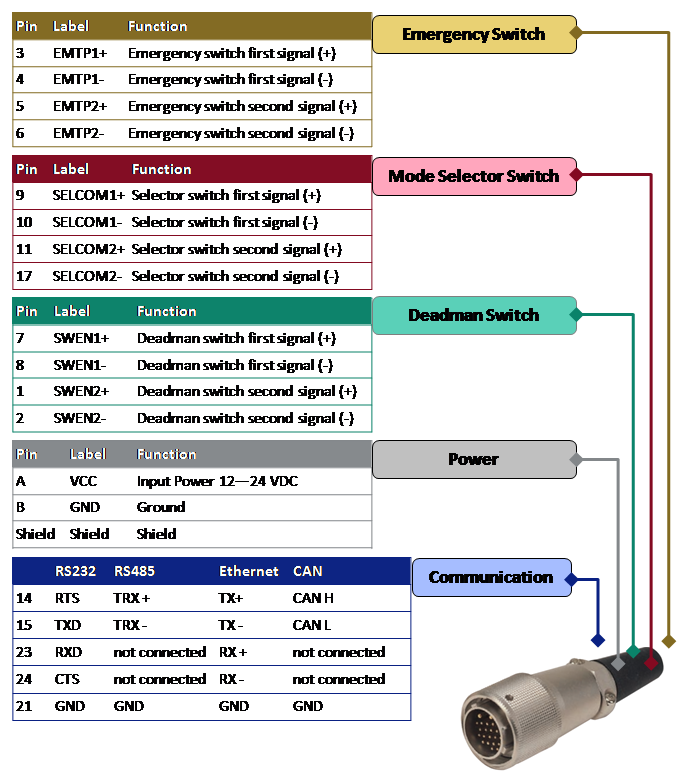

TP Cable Pin Assignments

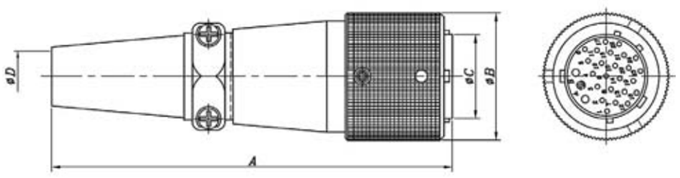

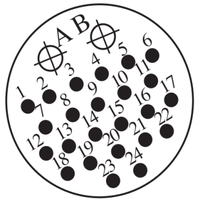

TP Cable Connector - Male

| Part Number | A | ΦB | ΦC | ΦD | |

|---|---|---|---|---|---|

| SRC6A21-26P | mm | 98.0 | 31.0 | 20.4 | 12.2 |

Jig Board

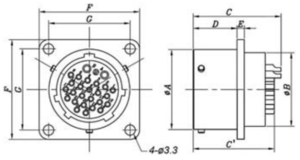

TP Cable Interface on Jig Board - Female

| Part Number | A | ΦB | C(C') | D | E | F | G | |

|---|---|---|---|---|---|---|---|---|

| SRC6A21-26P | mm | 25.6 | 20.4 | 27.7 (25.5) | 14 | 2.3 | 32 | 26 |

IO Cable Interface on Jig Board - Pin Assignments

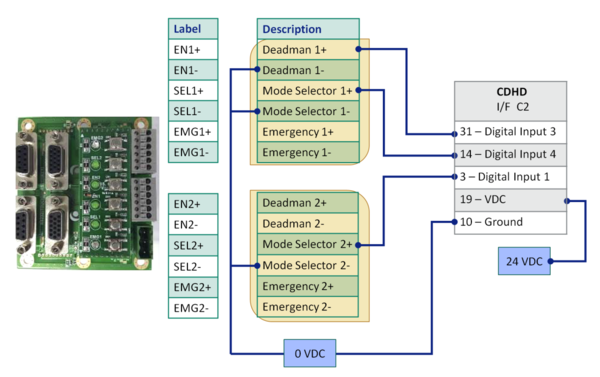

Example: connection to CDHD

- The Emergency and Deadman switches are connected to the safety circuit of the system (STO, safety relay) according to user requirements.

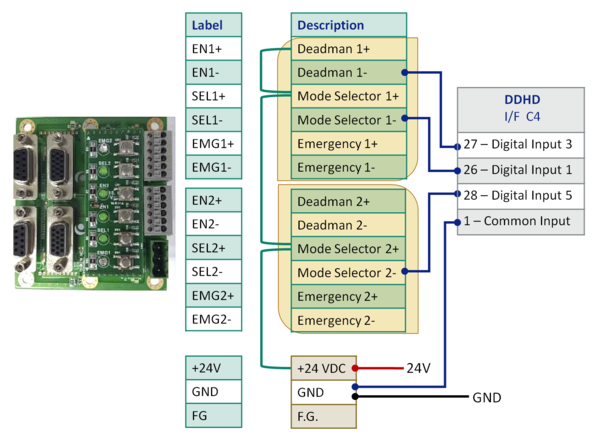

Example: connection to DDHD

- Different input order and no emergency switch connected. Green lines are bridges; red and black lines are from an outside source.

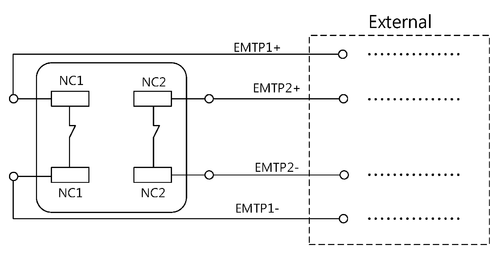

Emergency Switch

It is the user’s responsibility to connect the Emergency switch to the robotic system, and to follow all necessary safety guidelines and precautions.

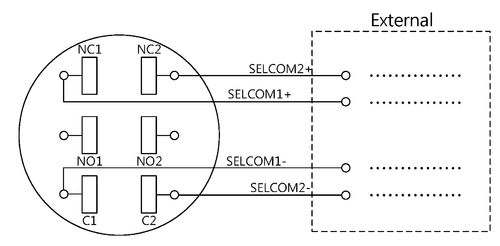

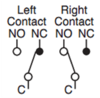

Selector Switch

| Position | Symbol |

|---|---|

| Left |

|

| Center |

|

| Right |

|