Difference between revisions of "4-Axis Delta robot Setup/zh-hans"

(Created page with "{{Languages}} = Introduction = link=http://softmc.servotronix.com/img_auth.php/9/94/Deltasim.html|400px <br/> <br/> In this example we will use soft...") |

(BackToTop button) |

||

| (One intermediate revision by one other user not shown) | |||

| Line 1: | Line 1: | ||

| − | {{Languages}} | + | {{Languages|4-Axis_Delta_robot_Setup}} |

| − | = | + | <div id="BackToTop" class="noprint" style="background-color:; position:fixed; bottom:32px; left:95%; z-index:9999; padding:0; margin:0;"> |

| + | <span style="color:blue; font-size:8pt; font-face:verdana,sans-serif; border:0.2em outset:#ceebf7; padding:0.1em; font-weight:bolder; -moz-border-radius:8px; "> | ||

| + | [[Image:TOP2.png|50px|link=#top]] </span></div> | ||

| + | |||

| + | = 简介 = | ||

[[File:PrevDeltasim.JPG|link=http://softmc.servotronix.com/img_auth.php/9/94/Deltasim.html|400px]] <br/> <br/> | [[File:PrevDeltasim.JPG|link=http://softmc.servotronix.com/img_auth.php/9/94/Deltasim.html|400px]] <br/> <br/> | ||

| − | + | 在这个例子中,我们将使用softMC模拟器来创建Delta机器人,从终端观看一些参数,最后用roboDK运行机器人。<br/> | |

| − | + | 我们从roboDK库中选择Delta机器人,机器人参数:<br/> | |

Rbig = 110 [mm]<br/> | Rbig = 110 [mm]<br/> | ||

L1 = 100 [mm]<br/> | L1 = 100 [mm]<br/> | ||

| Line 10: | Line 14: | ||

Rsmall = 40 [mm] <br/> | Rsmall = 40 [mm] <br/> | ||

Gear 1:10 <br/> | Gear 1:10 <br/> | ||

| − | + | 典型速度是 18,000/10 [deg/sec] 3000 [RPM] <br/> | |

| − | + | 典型最大速度 30,000/10 [deg/sec] <br/> | |

| − | + | 典型加速度/减速度 720,000/10 [deg/sec] <br/> | |

| − | + | 典型最大加速度/减速度 900,000/10 [deg/sec] <br/> | |

| − | + | 典型加加速度 2,160,000/10 [deg/sec] <br/> | |

| − | + | 典型最大加加速度 2,700,000/10 [deg/sec] <br/> | |

| − | + | 注意: <br/> | |

| − | + | 工具坐标值为: tool = #{0,0,15,0} <br/> | |

| − | = | + | = 运行softMC SIM = |

| − | + | 使用VM运行softMC模拟器,'''mc'''作为登录系统登录和密码,输入'''ifconfig'''找到softMC模拟器IP地址,在下面的例子中是'''192.168.56.103''' <br/> <br/> | |

[[File:DeltaEx01.JPG]] <br/> <br/> | [[File:DeltaEx01.JPG]] <br/> <br/> | ||

[[File:DeltaEx02.JPG]] <br/> <br/> | [[File:DeltaEx02.JPG]] <br/> <br/> | ||

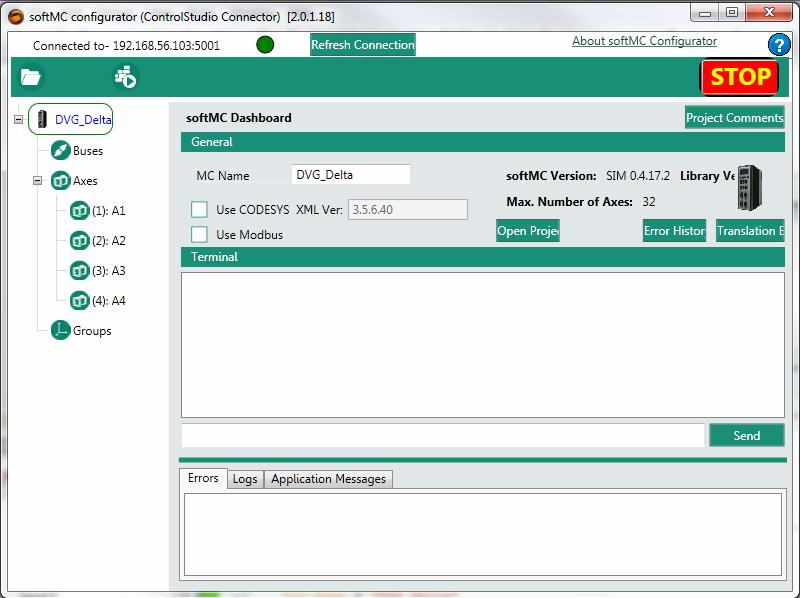

| − | = | + | = 运行ControlStudio = |

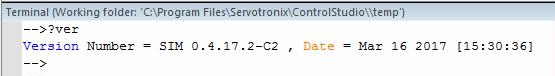

| − | + | 运行ControlStudio,并确保运行相应的固件版本,在下面的例子中,我们运行固件0.4.17.2-C2 <br/> <br/> | |

[[File:Delta2.jpg]] <br/> <br/> | [[File:Delta2.jpg]] <br/> <br/> | ||

[[File:Delta3.jpg]] <br/> <br/> | [[File:Delta3.jpg]] <br/> <br/> | ||

| − | = | + | = 创建并运行CONFIG.PRG文件 = |

| − | + | 配置器不生成CONFIG.PRG文件,这是必需的文件。<br /> | |

| − | + | 最简单的CONFIG.PRG文件将如下所示: | |

<syntaxhighlight lang="vb"> | <syntaxhighlight lang="vb"> | ||

Sys.NumberAxes = 4 | Sys.NumberAxes = 4 | ||

| Line 41: | Line 45: | ||

end program | end program | ||

</syntaxhighlight> | </syntaxhighlight> | ||

| − | + | 注意:由于Delta机器人需要4个轴,所以Sys.NumberAxes至少为4。 <br /> | |

| − | + | 在打开配置器之前,请确保通过使用'''"Save and Load"'''将其上传到softMC并在终端中发送'''">reset all"'''来运行CONFIG.PRG文件。 | |

| − | = | + | = 运行配置器打开新项目 = |

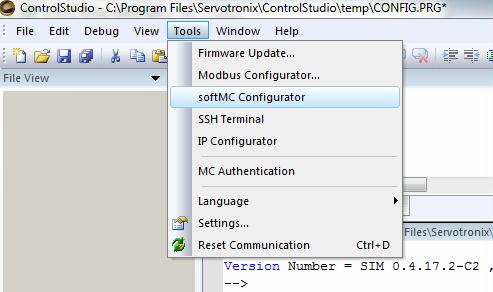

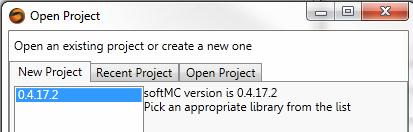

| − | + | 从ControlStudio运行配置程序并打开新的Project <br/> <br/> | |

[[File:Delta5.jpg]] <br/> <br/> | [[File:Delta5.jpg]] <br/> <br/> | ||

[[File:Delta6.jpg]] <br/> <br/> | [[File:Delta6.jpg]] <br/> <br/> | ||

| − | ''' | + | '''重要注意事项:''' <br/> |

| − | * | + | * 您在模拟中运行时,您在Buses文件夹下看不到任何驱动器 |

| − | * | + | * 确保能看到4个轴(A1 A2 A3 A4) |

[[File:Delta11.jpg]] <br/> <br/> | [[File:Delta11.jpg]] <br/> <br/> | ||

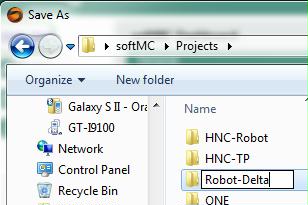

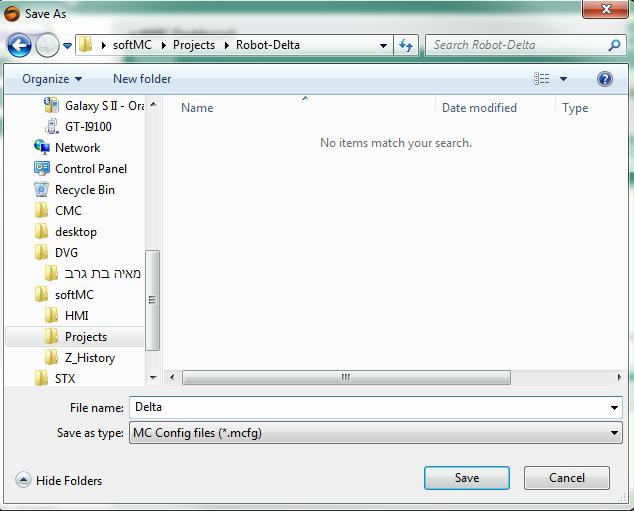

| − | = | + | = 创建新文件夹 = |

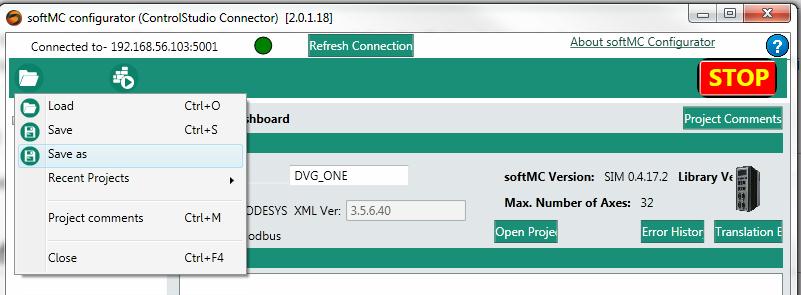

| − | + | 现在我们将创建我们的文件夹和我们的配置文件,我们将使用"Save As"创建"New"文件夹,并将我们的配置文件命名为Delta。 <br/><br/> | |

[[File:Delta7.jpg]] <br/> <br/> | [[File:Delta7.jpg]] <br/> <br/> | ||

[[File:Delta8.jpg]] <br/> <br/> | [[File:Delta8.jpg]] <br/> <br/> | ||

| Line 60: | Line 64: | ||

[[File:Delta10.jpg]] <br/> <br/> | [[File:Delta10.jpg]] <br/> <br/> | ||

| − | = | + | = 配置驱动器和轴 = |

| − | == | + | == 定义驱动器 == |

| − | + | 由于我们使用softMC模拟器,我们没有任何驱动器,可以跳到下一步 | |

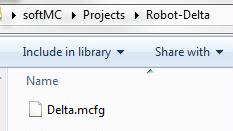

| − | == | + | == 定义轴 == |

| − | + | 点击第一个轴,其配置窗口将显示: <br /> | |

| − | # | + | # 选择"Axis Type"。Delta选择"Rotary Gear"。 <br /> |

| − | # | + | # 设置正确的减速比。 我们该值保持为1<br /> |

| − | + | 对每个使用的轴重复最后一步。 <br /> | |

[[File:Delta12.jpg]]<br /> | [[File:Delta12.jpg]]<br /> | ||

<br /> | <br /> | ||

| − | ''' | + | '''提示:''' <br/> |

| − | + | 如果您有类似的轴,您可以是用鼠标单击轴复制整个轴执行所有设置。 <br/><br/> | |

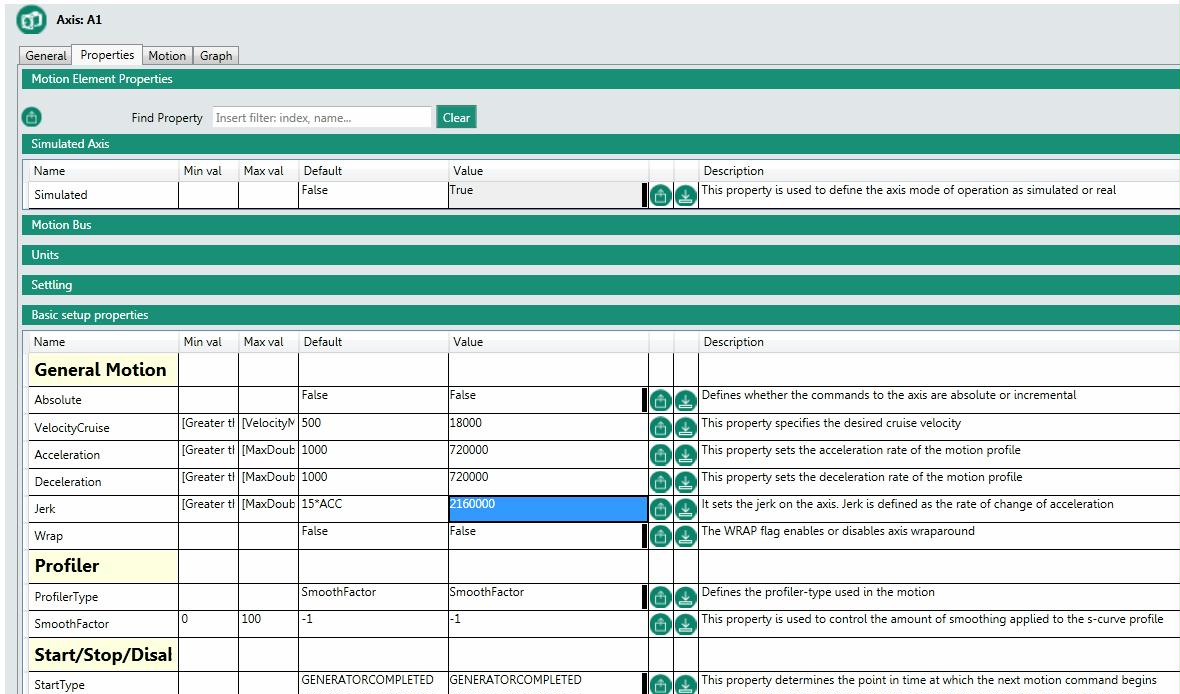

| − | + | 轴的配置窗口有一些选项卡。 '''"Properties"'''选项卡允许设置轴属性。 为每个轴适当设置以下属性 <br /> <br /> | |

| − | ''' | + | '''重要:''' 这些值是减速后的最终值 <br /> <br /> |

| − | + | 对于模拟机器人,将"Simulated Axis"属性更改为"True"<br /> | |

velocity is 18,000 [deg/sec] 3000 [RPM] <br/> | velocity is 18,000 [deg/sec] 3000 [RPM] <br/> | ||

max velocity is 30,000 [deg/sec] <br/> | max velocity is 30,000 [deg/sec] <br/> | ||

| Line 84: | Line 88: | ||

[[File:Delta14.jpg]]<br /> | [[File:Delta14.jpg]]<br /> | ||

| − | = | + | = 创建Delta机器人 = |

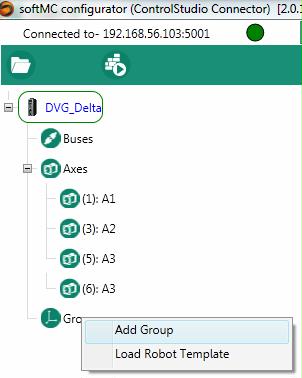

| − | + | 右键单击组图标,然后选择添加组 <br /> <br /> | |

[[File:Delta15.jpg]]<br /> <br /> | [[File:Delta15.jpg]]<br /> <br /> | ||

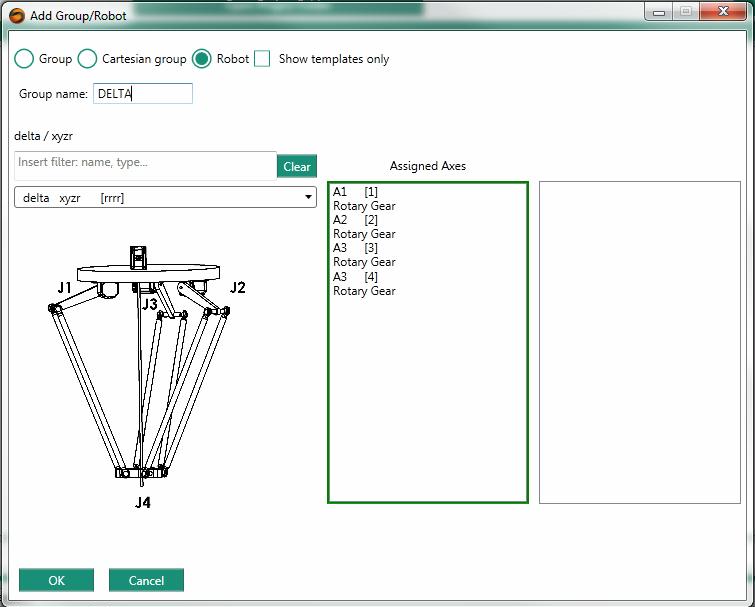

| − | + | 选择 '''Robot''' <br /> | |

| − | + | 组名称 '''DELTA'''<br /> | |

| − | + | 选择 '''delta xyzr [rrrr]''' <br /> | |

| − | + | 单击所有四轴,注意框架颜色从红色变为绿色。<br /> <br /> | |

[[File:Delta17.jpg]]<br /> | [[File:Delta17.jpg]]<br /> | ||

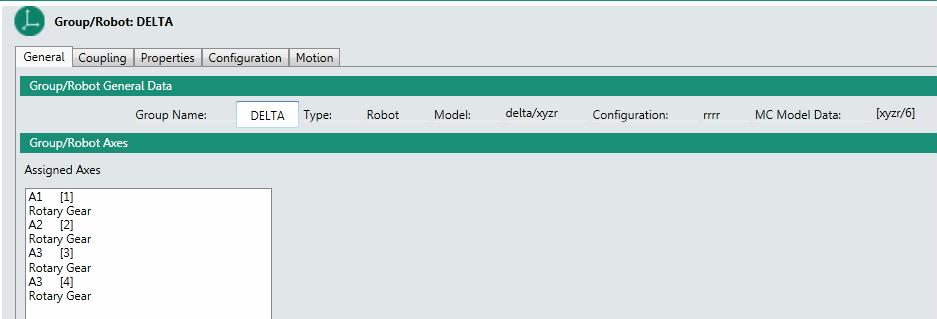

| − | == | + | == 综合 == |

| − | + | 此选项卡允许切换链接到组的轴,并更改轴属性,因为您有多于4轴。 | |

| + | <br /> <br /> | ||

[[File:Delta18.jpg]]<br /> | [[File:Delta18.jpg]]<br /> | ||

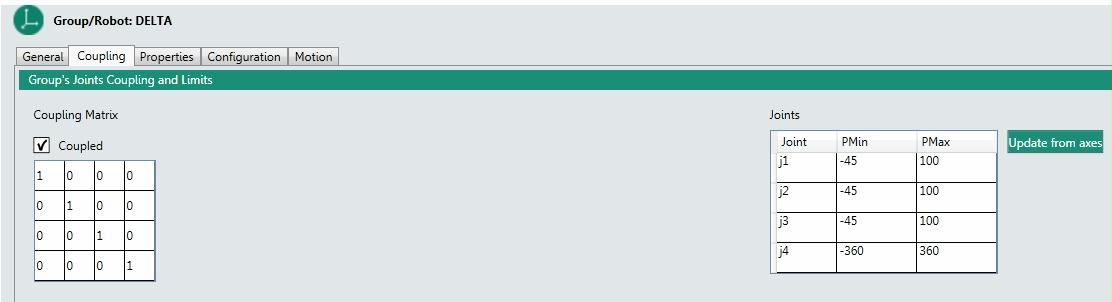

| − | == | + | == 耦合 == |

| − | # | + | # 对于Delta机器人,不应定义耦合矩阵(定义电机轴是否仅旋转特定关节或多于一个关节。) |

| − | # | + | # 每个轴的关节位置限制。 <br /> <br /> |

[[File:Delta19.jpg]]<br /> | [[File:Delta19.jpg]]<br /> | ||

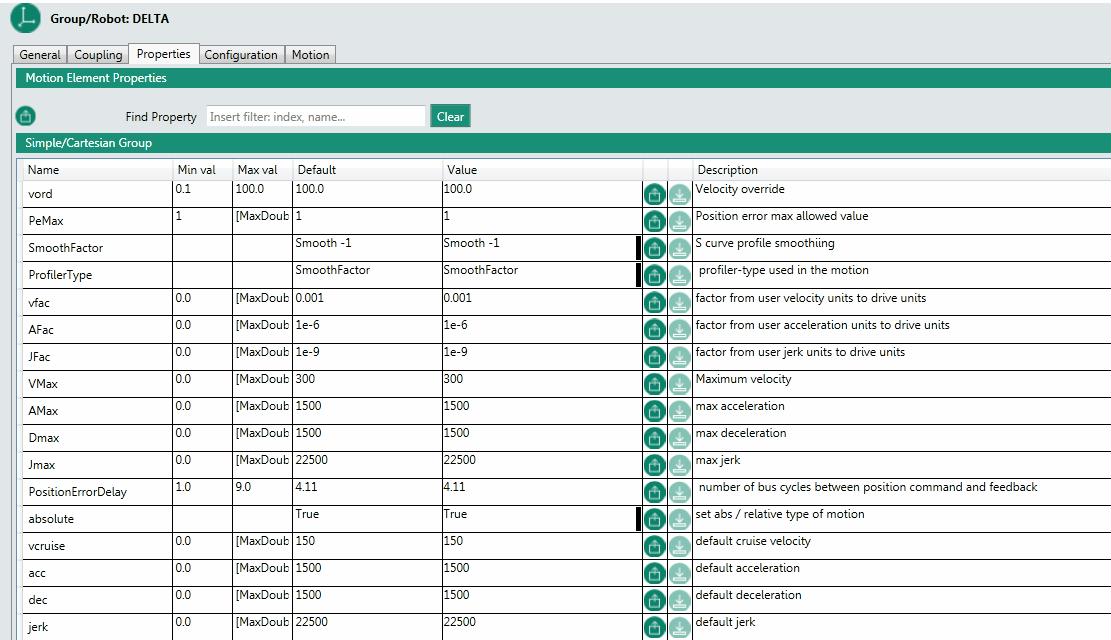

| − | == | + | == 属性 == |

| − | + | 此选项卡允许设置机器人属性,如:位置限制,速度限制,加速限制等<br /><br/> | |

| − | + | 注意: | |

| − | * | + | * 确保在simple/Cartesian表“PeMax”(-->delta.pemax=10)中将位置误差设置为最大值10 (-->delta.pemax=10) |

[[File:Delta20.jpg]]<br /> | [[File:Delta20.jpg]]<br /> | ||

| − | == | + | == 配置 == |

| − | + | 该选项表有3个子选项表: <br /> <br/> | |

| − | * | + | *确保将工具Z轴设置为15以适应RoboDK(-->delta.tool=#{0,0,15,0})<br /><br/> |

| − | + | 有关更多信息,请使用以下链接 <br/> | |

[[Robot_Working_Frames#BASE|base]] <br/> | [[Robot_Working_Frames#BASE|base]] <br/> | ||

[[Robot_Working_Frames#tool|tool]] <br/> | [[Robot_Working_Frames#tool|tool]] <br/> | ||

| Line 120: | Line 125: | ||

[[File:Deltatool.JPG]]<br /> | [[File:Deltatool.JPG]]<br /> | ||

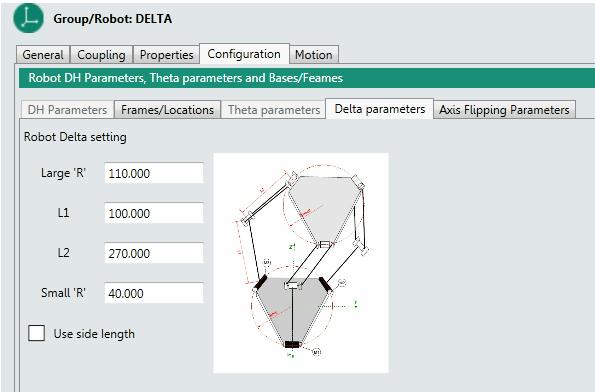

| − | === | + | === Delta参数 === |

| − | + | 这里我们设置Delta机器人的机械参数:<br/> | |

Rbig = 110 [mm]<br/> | Rbig = 110 [mm]<br/> | ||

L1 = 100 [mm]<br/> | L1 = 100 [mm]<br/> | ||

| Line 128: | Line 133: | ||

[[File:Delta22.jpg]]<br /> | [[File:Delta22.jpg]]<br /> | ||

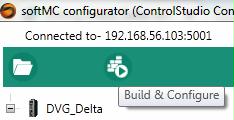

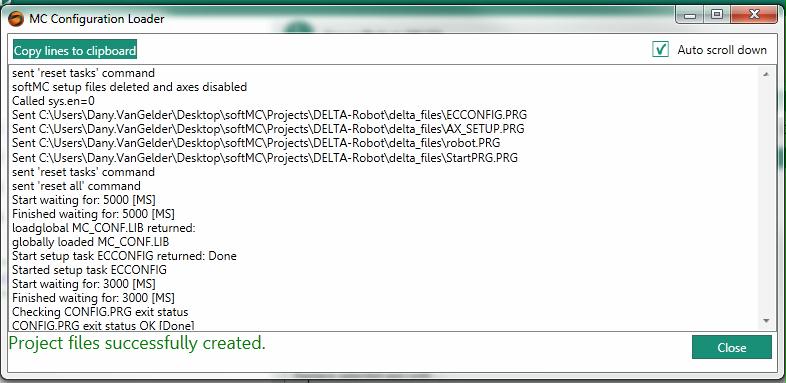

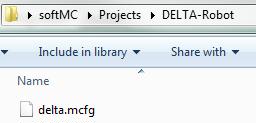

| − | = | + | = 建立&配置 = |

| − | + | 现在我们已经准备好生成安装和通信文件,并在softMC上运行它们,点击'''"Build | |

| + | &Configure"'''<br/> <br/> | ||

{| class="wikitable" | {| class="wikitable" | ||

|- | |- | ||

| Line 137: | Line 143: | ||

{| class="wikitable" | {| class="wikitable" | ||

|- | |- | ||

| − | ! scope="col"| | + | ! scope="col"|Build & Configure 前 || ! scope="col"| Build & Configure 后 |

|- | |- | ||

|[[File:Delta24.jpg]] ||[[File:Delta26.jpg]] | |[[File:Delta24.jpg]] ||[[File:Delta26.jpg]] | ||

| Line 146: | Line 152: | ||

|} | |} | ||

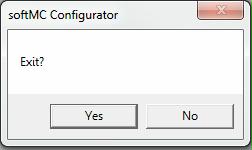

| − | = | + | = 关闭配置器 = |

| − | + | 现在退出配置程序,我们可以稍后再回到配置器。 <br/><br/> | |

[[File:Delta29.jpg]]<br /> | [[File:Delta29.jpg]]<br /> | ||

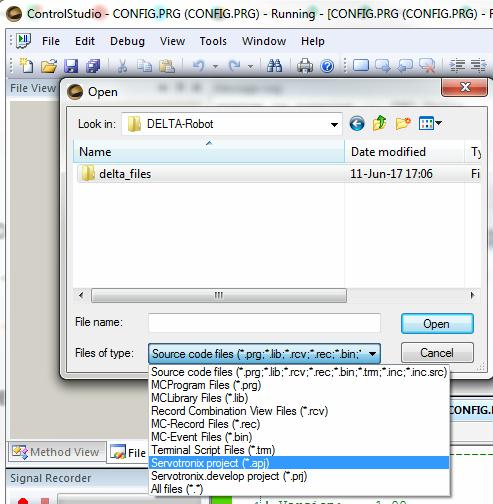

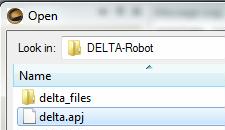

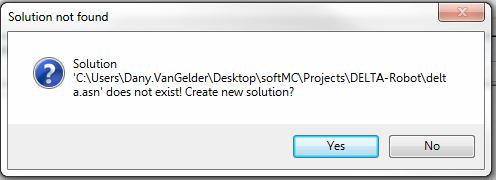

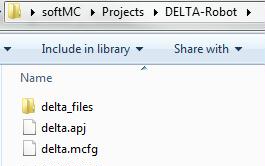

| − | = | + | = 创建解决方案 = |

| − | + | 要创建解决方案,我们必须执行以下操作: <br/> | |

| − | * | + | * 打开由Build&Configure创建的Project(apj文件) |

| − | * | + | * 将其另存为解决方案(asn文件) |

| − | * | + | * 将Config.prg从控制器添加到PC |

| − | * | + | * 使用资源管理器将任何用户预览程序复制到文件夹 |

| − | * | + | * 将文件添加到解决方案树 <br/> <br/> |

| − | ''' | + | '''打开工程''' (apj file) <br/> <br/> |

[[File:Delta30.jpg]]<br /> <br/> | [[File:Delta30.jpg]]<br /> <br/> | ||

[[File:Delta32.jpg]]<br /> <br/> | [[File:Delta32.jpg]]<br /> <br/> | ||

| − | ''' | + | '''另存为解决方案''' <br/> <br/> |

[[File:Delta33.jpg]]<br /> <br/> | [[File:Delta33.jpg]]<br /> <br/> | ||

[[File:Delta34.jpg]]<br /> <br/> | [[File:Delta34.jpg]]<br /> <br/> | ||

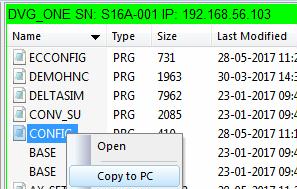

| − | ''' | + | '''将Config.prg从控制器添加到PC''' <br/> <br/> |

[[File:Delta35.jpg]]<br /> <br/> | [[File:Delta35.jpg]]<br /> <br/> | ||

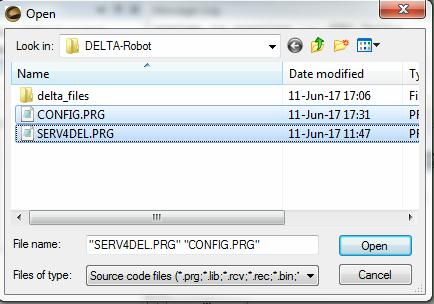

| − | ''' | + | '''将文件添加到解决方案树''' <br/> <br/> |

[[File:Delta36.jpg]]<br /> <br/> | [[File:Delta36.jpg]]<br /> <br/> | ||

[[File:Delta37.jpg]]<br /> <br/> | [[File:Delta37.jpg]]<br /> <br/> | ||

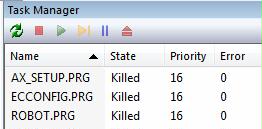

| − | = | + | = 添加监视 = |

| − | + | 我们可以从终端查看拥有的轴 <br/> | |

-->?grouplist <br/> | -->?grouplist <br/> | ||

DELTA:A1,A2,A3,A4 <br/> | DELTA:A1,A2,A3,A4 <br/> | ||

| − | + | 添加启用Delta机器人位置反馈和XYZR值的监视。 <br/><br/> | |

[[File:Delta38.jpg]]<br /> | [[File:Delta38.jpg]]<br /> | ||

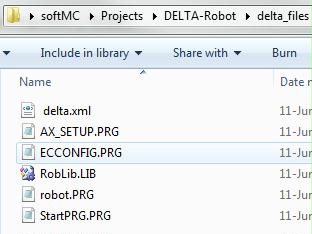

| − | = | + | = 运行机器人 = |

| − | == | + | == 现在运行机器人 == |

| − | + | 现在我们可以运行机器人 <br/> | |

-->Delta.en=1 <br/> | -->Delta.en=1 <br/> | ||

-->move delta {0,0,0,20} <br/> | -->move delta {0,0,0,20} <br/> | ||

| − | == | + | == 重新循环运行机器人 == |

| − | + | 执行以下操作: | |

| − | * | + | * 运行并启动softMCSIM |

| − | * | + | * 运行ControlStudio并连接到您的softMCSIM |

| − | * | + | * 打开您的"Delta" 解决方案 |

| − | * | + | * 双击程序文件"StartPRG.PRG" |

| − | * | + | * 点击图标"Save and Load" |

| − | ''' | + | '''Delta 机器人就绪''' |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | = 用roboDK运行机器人 = | ||

| + | == 打开TCP / IP服务器以使用RoboDK == | ||

| + | 保存加载并运行SERV4DEL.PRG,确保您在ControlStudio消息日志中看到"socket 2 is set"<br/> | ||

| + | 提示:使用Windows键+左边的错误,在左半边的窗口上得到ControlStudio。 | ||

<syntaxhighlight lang="vb"> | <syntaxhighlight lang="vb"> | ||

' Version: 1.00 | ' Version: 1.00 | ||

| Line 331: | Line 336: | ||

</syntaxhighlight> | </syntaxhighlight> | ||

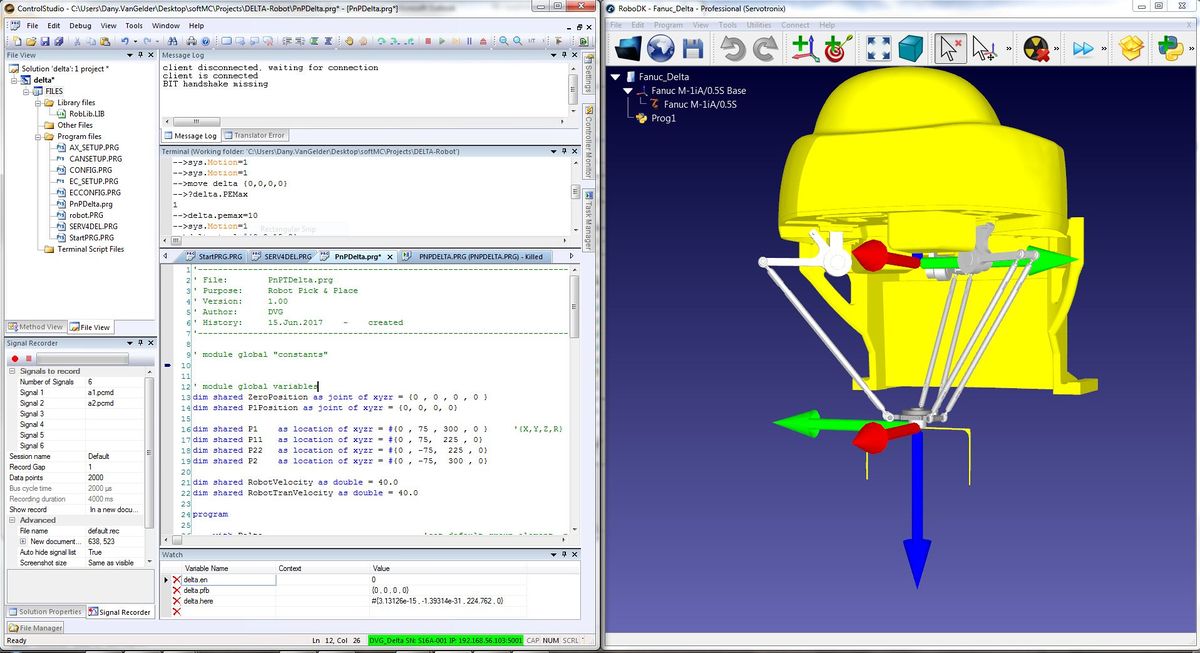

| − | == | + | == 运行RoboDK == |

| − | + | 复制粘贴到由Servotronix编写的文件夹“Fanuc_Delta.rdk”包括 | |

| − | * | + | * 来自RoboDK库的Delta机器人 |

| − | * | + | * Prog1一个pyton脚本,打开TCP / IP套接字以使用softMCSIM / serv4del.prg |

| − | + | 双击Prog1图标打开RoboDK TCP / IP端口,并确保您在ControlStudio消息中看到"client | |

| + | is connected" | ||

{| class="wikitable" | {| class="wikitable" | ||

| Line 368: | Line 374: | ||

</syntaxhighlight> | </syntaxhighlight> | ||

| − | = | + | = 机器人程序示例 = |

| − | + | 这是一个简单的拾取和放置程序,其中P12和P11是较高的位置,P2和P1是较低的位置。 <br/> <br/> | |

| − | |||

|[[File:DeltaCapture01.JPG|1200px]] <br/> | |[[File:DeltaCapture01.JPG|1200px]] <br/> | ||

Latest revision as of 06:14, 10 August 2017

| 语言: | English • 中文(简体) |

|---|

Contents

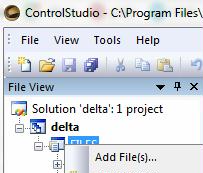

简介

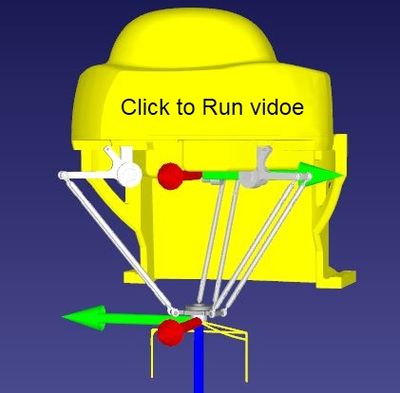

在这个例子中,我们将使用softMC模拟器来创建Delta机器人,从终端观看一些参数,最后用roboDK运行机器人。

我们从roboDK库中选择Delta机器人,机器人参数:

Rbig = 110 [mm]

L1 = 100 [mm]

L2 = 270 [mm]

Rsmall = 40 [mm]

Gear 1:10

典型速度是 18,000/10 [deg/sec] 3000 [RPM]

典型最大速度 30,000/10 [deg/sec]

典型加速度/减速度 720,000/10 [deg/sec]

典型最大加速度/减速度 900,000/10 [deg/sec]

典型加加速度 2,160,000/10 [deg/sec]

典型最大加加速度 2,700,000/10 [deg/sec]

注意:

工具坐标值为: tool = #{0,0,15,0}

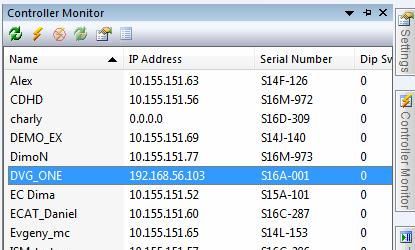

运行softMC SIM

使用VM运行softMC模拟器,mc作为登录系统登录和密码,输入ifconfig找到softMC模拟器IP地址,在下面的例子中是192.168.56.103

运行ControlStudio

运行ControlStudio,并确保运行相应的固件版本,在下面的例子中,我们运行固件0.4.17.2-C2

创建并运行CONFIG.PRG文件

配置器不生成CONFIG.PRG文件,这是必需的文件。

最简单的CONFIG.PRG文件将如下所示:

Sys.NumberAxes = 4

program

Sys.Name = "DVG_Delta"

Print "system is running - " ; Sys.Name

Sys.DoubleFormat = 1 ; viewing the watch number

end program

注意:由于Delta机器人需要4个轴,所以Sys.NumberAxes至少为4。

在打开配置器之前,请确保通过使用"Save and Load"将其上传到softMC并在终端中发送">reset all"来运行CONFIG.PRG文件。

运行配置器打开新项目

从ControlStudio运行配置程序并打开新的Project

重要注意事项:

- 您在模拟中运行时,您在Buses文件夹下看不到任何驱动器

- 确保能看到4个轴(A1 A2 A3 A4)

创建新文件夹

现在我们将创建我们的文件夹和我们的配置文件,我们将使用"Save As"创建"New"文件夹,并将我们的配置文件命名为Delta。

配置驱动器和轴

定义驱动器

由于我们使用softMC模拟器,我们没有任何驱动器,可以跳到下一步

定义轴

点击第一个轴,其配置窗口将显示:

- 选择"Axis Type"。Delta选择"Rotary Gear"。

- 设置正确的减速比。 我们该值保持为1

对每个使用的轴重复最后一步。

提示:

如果您有类似的轴,您可以是用鼠标单击轴复制整个轴执行所有设置。

轴的配置窗口有一些选项卡。 "Properties"选项卡允许设置轴属性。 为每个轴适当设置以下属性

重要: 这些值是减速后的最终值

对于模拟机器人,将"Simulated Axis"属性更改为"True"

velocity is 18,000 [deg/sec] 3000 [RPM]

max velocity is 30,000 [deg/sec]

Acceleration/Deceleration 720,000 [deg/sec]

Max Acceleration/Deceleration 900,000 [deg/sec]

Jerk is 2,160,000 [deg/sec]

max Jerk is 2,700,000 [deg/sec]

Position error max 10

创建Delta机器人

右键单击组图标,然后选择添加组

选择 Robot

组名称 DELTA

选择 delta xyzr [rrrr]

单击所有四轴,注意框架颜色从红色变为绿色。

综合

此选项卡允许切换链接到组的轴,并更改轴属性,因为您有多于4轴。

耦合

- 对于Delta机器人,不应定义耦合矩阵(定义电机轴是否仅旋转特定关节或多于一个关节。)

- 每个轴的关节位置限制。

属性

此选项卡允许设置机器人属性,如:位置限制,速度限制,加速限制等

注意:

- 确保在simple/Cartesian表“PeMax”(-->delta.pemax=10)中将位置误差设置为最大值10 (-->delta.pemax=10)

配置

该选项表有3个子选项表:

- 确保将工具Z轴设置为15以适应RoboDK(-->delta.tool=#{0,0,15,0})

有关更多信息,请使用以下链接

base

tool

machinetable

workpiece

Delta参数

这里我们设置Delta机器人的机械参数:

Rbig = 110 [mm]

L1 = 100 [mm]

L2 = 270 [mm]

Rsmall = 40 [mm]

建立&配置

现在我们已经准备好生成安装和通信文件,并在softMC上运行它们,点击"Build

&Configure"

|

---> |

|

| Build & Configure 前 | Build & Configure 后 |

|---|---|

|

|

| |

|

关闭配置器

创建解决方案

要创建解决方案,我们必须执行以下操作:

- 打开由Build&Configure创建的Project(apj文件)

- 将其另存为解决方案(asn文件)

- 将Config.prg从控制器添加到PC

- 使用资源管理器将任何用户预览程序复制到文件夹

- 将文件添加到解决方案树

添加监视

我们可以从终端查看拥有的轴

-->?grouplist

DELTA:A1,A2,A3,A4

添加启用Delta机器人位置反馈和XYZR值的监视。

运行机器人

现在运行机器人

现在我们可以运行机器人

-->Delta.en=1

-->move delta {0,0,0,20}

重新循环运行机器人

执行以下操作:

- 运行并启动softMCSIM

- 运行ControlStudio并连接到您的softMCSIM

- 打开您的"Delta" 解决方案

- 双击程序文件"StartPRG.PRG"

- 点击图标"Save and Load"

Delta 机器人就绪

用roboDK运行机器人

打开TCP / IP服务器以使用RoboDK

保存加载并运行SERV4DEL.PRG,确保您在ControlStudio消息日志中看到"socket 2 is set"

提示:使用Windows键+左边的错误,在左半边的窗口上得到ControlStudio。

' Version: 1.00

' Author: Ron Danon DVG

' Description:

' History: 2017-06-17 base on server.prg V1.00

' Created

'------------------------------------------------------------------------------

dim shared numOfRobots as long = 1

program continue

dim index as long

dim sockNum as long = 2

dim cPort as long = 7132

dim jointStr as string

dim robotGroups[1] as generic group 'same as size of numOfRobots

dim robotNames[1] as string 'same as size of numOfRobots

'---------------Define robot groups and names---------------'

robotGroups[1] = DELTA

robotNames[1] = "robot1"

'robotGroups[2] = PUMA2

'robotNames[2] = robot2

'---------------Opening new socket---------------'

call openNewSocket(sockNum,cPort)

'---------------Connecting to client---------------'

call connectClient(sockNum,cPort,0)

'---------------Main Loop---------------'

while True

call createJsonStr(robotNames,robotGroups,jointStr)

call checkIfReady(sockNum,cPort)

' ?jointStr

' ?SIZE(jointStr)

print #sockNum,jointStr

end while

'---------------Close sockets and exit---------------'

print #sockNum,"finish"

sleep 1000

close #sockNum

Print "Server Closed Sockets. Server Exits"

end program ' server.prg

'---------------------------------------'

'---------------Functions---------------'

'---------------------------------------'

sub openNewSocket(sockNum as long,cPort as Long)

dim opened as long = 0

while not opened

Try

OpenSocket Options=1 as #sockNum

opened = 1

catch 5043 'socket is already open

print "socket", sockNum, "is already open. trying next socket"

sockNum = sockNum + 1

end Try

end while

print "socket", sockNum, "is set"

end sub

sub connectClient(sockNum as long, cPort as Long, ByVal sockIsOpen as long)

dim str1 as string

if sockIsOpen then

close #sockNum

OpenSocket Options=1 as #sockNum

end if

Accept(#sockNum, cPort)

sleep 500

str1=input$(loc(sockNum),#sockNum) 'receive data to check if connected

?"client is connected"

sleep 200

end sub

sub checkIfReady(sockNum as long,cPort as Long)

'Waits for a 'ready' input from roboDK before sending the next JSON string

dim ready as long = 0

while not ready

Try

while loc(sockNum) = 0 'while no data is available

sleep 10

end while

catch 5041 'client disconnected

print "client disconnected, waiting for connection"

call connectClient(sockNum,cPort,1)

end Try

ready = (input$(loc(sockNum),#sockNum) = "ready") 'check if the input is "ready"

end while

end sub

sub createJsonStr(robotNames[*] as string, robotGroups[*] as generic group, jointStr as string)

'FORMAT --> '{"robotName": [double-a1, double-a2, double-a3, double-a4, double-a5, double-a6]}' <---

'double is in precision of 2 digits after the point, i.e.: '0.12', '179.12'

dim index1 as long

dim index2 as long

dim jointValues as generic joint

dim temp as long = 50

jointStr = "{"

for index1 = 1 to numOfRobots

jointValues = robotGroups[index1].PFb

jointStr = jointStr + chr$(34) + robotNames[index1] + chr$(34) + ": ["

for index2 = 1 to robotGroups[index1].ElementSize

if index2 = 4 then

temp = 0

else

temp = 50

end if

jointStr = jointStr + STRD$(-jointValues{index2} + temp, "%.2f") + ", "

next

jointStr = LEFT$(jointStr,LEN(jointStr)-2) + "], "

next

jointStr = LEFT$(jointStr,LEN(jointStr)-2) + "}"

end sub

'---------------End of functions---------------'

运行RoboDK

复制粘贴到由Servotronix编写的文件夹“Fanuc_Delta.rdk”包括

- 来自RoboDK库的Delta机器人

- Prog1一个pyton脚本,打开TCP / IP套接字以使用softMCSIM / serv4del.prg

双击Prog1图标打开RoboDK TCP / IP端口,并确保您在ControlStudio消息中看到"client is connected"

| TCP/IP port Close |

TCP/IP port Open |

|---|---|

Prog1

import mcEnv

host, port = "192.168.56.103", 7132

finsihedTransmit = False

MCE = mcEnv.MCenv()

MCE.setSimulationSpeed(1000)

MCE.connectClient(host,port)

MCE.setRobot("robot1", "Fanuc M-1iA/0.5S")

robotList = ["robot1"]

while not finsihedTransmit:

MCE.writeStr("ready")

jsonStr = MCE.readJsonStr()

MCE.moveRobots(robotList, jsonStr)

raise Exception('Finished')

机器人程序示例

这是一个简单的拾取和放置程序,其中P12和P11是较高的位置,P2和P1是较低的位置。

|

'------------------------------------------------------------------------------

' File: PnPTDelta.prg

' Purpose: Robot Pick & Place

' Version: 1.00

' Author: DVG

' History: 15.Jun.2017 - created

'------------------------------------------------------------------------------

' module global "constants"

' module global variables

dim shared ZeroPosition as joint of xyzr = {0 , 0 , 0 , 0 } 'Moving as joint - for initial positioning

dim shared P1Position as joint of xyzr = {0, 0, 0, 0} '{J1,J2,J3,J4}

dim shared P1 as location of xyzr = #{0 , 75 , 300 , 0 } '{X,Y,Z,R}

dim shared P11 as location of xyzr = #{0 , 75, 225 , 0}

dim shared P22 as location of xyzr = #{0 , -75, 225 , 0}

dim shared P2 as location of xyzr = #{0 , -75, 300 , 0}

dim shared RobotVelocity as double = 40.0

dim shared RobotTranVelocity as double = 40.0

program

with Delta 'set default group element, no need to explicitly indicate the motion element

Attach 'Attach the task to motion element (with Delta)

En = TRUE

Sleep 100

Vcruise = RobotVelocity 'Set robot's cruise velocity

Vtran = RobotTranVelocity

while NOT En

Sleep 100

end while

Move ZeroPosition 'moving to zero position

WaitForMotion Delta

call pickPlaceXYZ 'execute Pick and Place function

Move ZeroPosition

WaitForMotion Delta

Detach

end with

end program

sub pickPlaceXYZ

dim i as long

Move Delta P1Position

WaitForMotion Delta

Delta.BlendingMethod = 2 'Type of motion blending - 2 is SuperPosition blending - in order to optimize movement, so that it will be as fast as possible

Delta.BlendingFactor = 80 'Percentage of the movement’s length that will not be blended with the next movement

Delta.Cp = 10 'At continous path blednign, sets the blend radious value - bigger equal smoother

for i = 1 to 10

Moves Delta P11

WaitForMotion Delta

Moves Delta P1

WaitForMotion Delta

Moves Delta P11

WaitForMotion Delta

Moves Delta P22

WaitForMotion Delta

Moves Delta P2

WaitForMotion Delta

Moves Delta P22

WaitForMotion Delta

next i

Move Delta ZeroPosition

WaitForMotion Delta

end sub