Multi-Axis Kinematics

Non-homogenous groups consist of different axes, both rotary and linear. A feature was added to support the definition of velocities for non-homogenous groups. In the setup, rotary and linear axes are declared. The system determines if it is a linear- or rotary-dominant group. For example, in SCARA robot, there are two rotary axes for the first and second joints and another rotary axis for the last joint (roll). There is only one linear axis (the Z axis). Such a system is rotary-dominant.

Another example is the OCP system, which is an XY Gantry system with the last two axes taken from the SCARA. Here, there are two linear (X & Y) axes and another linear (Z axis) with just one rotary axis (roll). In this case, the system is linearly-dominant.

Axis setup defines the group behavior. Each axis must be declared whether it is linear or rotary by setting POSITIONROLLOVERENABLE to either zero(0) for linear or one (1) for rotary.

In non-homogenous groups, commanded velocity is always given according to the group dominancy type. If the group is linearly-dominant, the velocity (VCRUISE, VFINAL) is in linear units (mm/sec). The other non-linear axes are checked in the preparation phase of the movement. The velocity in these axes cannot exceed the maximum value. If it does, the overall (group) velocity is reduced.

There is only one exception to this rule. This is when a group movement is issued with only one axis in motion and all the others are stopped. Then, the given value of the velocity is taken directly in the units for that axis. For example, having movement on the third axis of the SCARA robot, the velocity value is in mm/sec.

The same is true for both acceleration and jerk values for group-interpolated motion.

Contents

- 1 Coordinate Systems

- 2 Coupling

- 3 POINTS

- 3.1 Declaration

- 3.2 Variables

- 3.3 Constant Points

- 3.4 Vectors

- 3.5 Properties

- 3.6 Point Dimension

- 3.7 Point Assignment

- 3.8 Single Coordinate Point Assignment

- 3.9 Point Query

- 3.10 Single Coordinate Point Query

- 3.11 Operators

- 3.12 Points in Functions

- 3.13 Motion Commands

- 3.14 Analog Behavior

- 3.15 Point As An Expression

- 3.16 Group Point Properties

- 3.17 In Functions

- 3.18 Query

- 3.19 Operators

- 3.20 Pass Structure

- 3.21 Limitations

Coordinate Systems

Having different world and joint coordinates make the robot kinematics unique. The world coordinates are normally perceived as working coordinates of an application. Usually, there is some form of Cartesian coordinate system originating in the robot base.

Another set of coordinates is added for the orientation of the end-effector (gripper, etc.). The orientation of a body in space is normally described by three angles. Depending on the number of degrees of freedom (motors used to actuate the orientation joints), they could be unequal. The world space coordinates are given by its position part (X, XY or XYZ tupple), in most cases. In general, it could be anything from sphere coordinates to cylindrical system. The orientation component can use many forms for describing orientation. The most used coordinate system for orientation angles are Euler angels: yaw, pitch and roll. The Euler angles can have two or more variations, according to the order of the accepted rotations (XYX, XZX etc.).

The joint space of a robot is a relatively simple concept. A joint coordinate is a number uniquely describing the position of a robot segment relative to the previous robot segment. If the joint connecting the segment is rotary, the joint coordinates are in degrees of the rotation angle. If it is linear, the joint coordinates are the linear displacement (millimeters).

The concept of joint coordinates is an n-tupple number. Each number represents the coordinate of the specific joint. The world coordinates are supported by different built-in types (XY, XYZ, XYZR) that describe each of the different world space representations. Theoretically, there can be different world space descriptions for the same (or same dimensional) world coordinates. Each robot has its default world-space type. Different robots could have same world space types, as long as they have same number of degrees of freedom (NDOF). For example, xy-table world space has XY world space descriptors. A SCARA robot having a Z axis for vertical motion and a roll axis for orientation uses world frame coordinates consisting of: X, Y, Z and roll or an XYZR descriptor.

The different coordinate systems are implemented as variables of different data types. Generally, a point in a coordinate system is defined as a point data type. Depending on if it is a joint space or world space, the sub-type of the point differs. There is a point data type with two subtypes: JOINT and LOCATION. Both have a world space descriptor that additionally differentiates between the same subtypes. A world space coordinate is stored in a variable and is defined as:

DIM A AS LOCATION OF XYZR

The joint space is:

DIM A AS JOINT OF XYZR

The new point data type with its two subtypes (LOCATION and JOINT) and the world-space descriptor (XY, XYZ, XYZR, etc.) covers all the possible robot space variations. These variables are independent of the robot and can be used without having a robot defined in the system. When they are used in a connection with the robot or a group, the world-subtypes must be equal.

Internally, points are stored as 10-dimensional vectors with a flag describing the subtype and a size defining the dimension size of a point. The point can be manipulated as a numeric data type using all the arithmetic operations available (+-*/). The operations are defined as coordinate-by-coordinate operations. Only points of the same subtype and same world-space can be combined.

Special syntax is used for point constants: a list of values separated by commands inside squared brackets ({}) denote points. If it is preceded by pound sign (#), it is a location:

DIM C AS LOCATION OF XYZR

C = #{0,0,0,0}DIM I AS JOINT OF XYZR

I = {0,0,0,0}

User Units

The MC gives you the freedom to change and choose different units. Robot models have less flexibility. Due to a tight relation between joint and world-space, you must define joint position units in millimeters or degrees and all time units in seconds so both world space and joint space are compatible units. The units of world space are automatically set to millimeters-degrees-seconds.

Each axis has four scaling factors: PFAC,VFAC, AFAC, and JFAC. These translate encoder/resolver counts into user position units (inches, millimeters or revolutions). They also specify what time units are used in position derivations (VEL, ACC, JERK). As the position factor defines the ratio between counts and user position units, the rest of the factors define the ratio between milliseconds and user time units. Typically you have:

<axis>.pfac = <number of counts per user position units> <axis>.vfac = pfac/1000 (if in seconds) <axis>.afac = vfac/1000 (if in seconds) <axis>.jfac = afac/1000 (if in seconds)

Once all axes are set up, groups contain these axes. You must have the same user units on all axes. Set the group scaling factors. There is no position factor for the group! Instead, PFAC for each axis is used.

MOVE g1 {1,2,3} vcruise = 10

Target coordinates are given to each axis and translated into encoder/resolver counts using PFAC for each axis. VCRUISE is not related to any axis. Group factors, VFAC, AFAC, and JFAC are used. The group velocity is expressed in position user units per seconds.

To have system units properly working, set the unit factors (PFAC, VFAC, AFAC and JFAC) of each axis to millimeters-degrees-seconds and set group units to seconds:

<group>.vfac = 1/1000 <group>.afac = vfac/1000 <group>.jfac = afac/1000

Coupling

In many robotics applications, mechanical construction introduced mechanical coupling between the axes. In such cases, two or more motors move only one joint. So activating only one motor causes motion in two axes (joints). There are many examples of such mechanical setups. Usually when the motors are dislocated for the joints, they are actuating. When the motor-actuating second joint is placed before the first joint, the second joint is moved by the motions of the first and second motors. Typical examples of such applications are displaced motors of a robotic arm (PUMA) moving the robot arm via chains or belts. Differential gearing on the last robot segment displaces the last motor (roll) from the end effector and both the fifth and sixth motors introduce motions on the sixth and with joint (Staubli RX series).

Staubli RX – pair axes a5 ,a6:

j6.pcmd = a6.pcmd – a5.pcmd

BOSCH – SCARA – pair axes a3,a4:

j3.pcmd = a3.pcmd + 18.3*a4.pcmd.

PUMA – a2,a3 and a4:

j4.pcmd=a2.pcmd+a3.pcmd+a4.pcmd.

Scaling and Rotation:

j1 = 707.1*a1.pcmd + 707.1*a2.pcmd j2 = 707.1*a1.pcmd + 707.1*a2.pcmd

Orthogonal Correction:

j1 =10000*a1.pcmd j2 = 2.91*a1.pcmd + 10000*a2.pcmd

Group joints are standard in the MC's firmware, covering coupling examples given above.

Motion Elements

The MC is a multi-axis and multi-group system. In many aspects, groups and axes are the same. For example, both have properties like: AMAX, VMAX, VCRUISE. Another common aspect is the movement in both of them. MOVE moves both axes and groups. Although, there are motion commands that are group-only (CIRCLE, MOVES) or axis-only (JOG), when moving an axis separately, it is not possible to move the group containing the same axis and vice versa. The axis is active in a group. ATTACH and DETACH work the same way. You cannot attach an axis when its group is already attached. So, we can denote both axes and groups using one term, motion-element.

There are some properties that are axis- or group-only properties. For example DRIVEADDRESS is an axis-only property.

MOVE consists two different command behaviors, Move-Group and Move-Axis. Move-Group moves the whole group together. All the axes within the group start and end the motion at the same time. Move-Group stays within the kinematics limits (VELOCITY, ACCELERATION, JERK) of the group and axes. The group limits are taken and imposed on the group motion (aggregate, space – XY, XYZ). The axis limits are imposed only proportionally to the ratio of the axis motion to the whole group motion. If axis X is moving halfway toward axis Y, only half the limit values are used. The total time of the motion is the time required for the slowest axis to accomplish the movement. Here, the slowest axis is the one with the largest path/velocity ratio and not necessary the axis with smallest maximum velocity (because if such an axis has no movement to make, it is not the slowest axis). On the other hand, Move-Axis checks only the limits of the specified axis and is independent of the limits of any group using this axis.

Profiler preparations can additionally reduce the motion parameter. This is typical for short movements where the given cruise velocity cannot be reached due to existing limitations of ACCELERATION and JERK.

Joints

Joints are virtual axes. Joints give the illusion of only one axis, both from the language point of view and looking at the physical movement of the coupled axis. The joint is analogous to an axis. Joints are denoted as J1, J2, etc.

Each joint actually represents one or several axes of the group, according to the given coupling matrix. If the group has no coupling matrix defined, the joint is a direct representation of the axis of the same ordinal number in the group as the joint index. To introduce another term, the "shadow-axis" of a joint is the axis with the same ordinal number in the group as the joint index. For example, if a group consists of axes A2, A3, A4, the shadow-axis of the joint J1 is A2.

Normally, all joint properties are a direct representation (have the same value) of shadow-axis properties, independent of whether the coupling matrix is defined or not. The only exceptions are properties related to joint position: PCMD, PFB, VCMD, VFB, CCMD, CFB, PMAX, and PMIN. These are unique for each joint.

Current positions and velocities are obtained according to the given coupling matrix. They are computed each time a query of these values is issued (PCMD, PFB, etc.). They are read-only and do not represent any specific internal variable. Symmetrically the same properties, when queried from a group (?g1.PCMD), return lists of joint-property values according to the coupling matrix. The movement’s target positions (MOVE or CIRCLE) of group movements are treated analogously (coupling matrix).

On the other hand, the joint’s position limits (PMAX and PMIN) are added to the joints. The position limit of the joint and the position limit of the shadow-axis are not related, but independent of whether the coupling matrix is defined or not. The joint position limits are always used when the coupling matrix is defined (COUPLED = 1). In this case, the shadow-axis limits are not used. This is only true for joint and group movements. Single-axis movement (e.g., MOVE A1 100) is limited only by the axis limits, independent of coupling.

Joints represent several axes of a group. Joint movements are actually group movements:

Move-Group = Move-Joint

Joint movement gives the illusion of moving one physical axis (MOVE J1 100), although several motors could be moving together. The movement is executed according to the specified joint’s movement parameters. For example:

A1.Acc = 100 MOVE A1 50

Is analogous to:

J1.Acc = 100 MOVE J1 50

Move-Joint simulates the behavior of moving a single axis by moving a single joint both by the parameters and physical motion. The only difference is that several motors are moving instead of just one. When moving joints, all motor limits within each group axis are checked. The joint movement is a group movement of one joint-coordinate with the group motion parameters copied from the shadow-axis. The following translation rule is true:

MOVE J1 10

' MOVE {10,0,0,0} abs = J1.abs vcruise = J1.vcruise acc = J1.acc

. . .

The same rules of group-motion apply.

Robot Models

A robot is defined as a group with a special model type. Currently, the following kinematics models are available:

1 – regular group: no kinematic model (default value)

2 – PUMA: 6 axis, XYZYPR (X,Y,Z, Yaw, Pitch, Roll)

4 – SCARA: 4 axis, XYZR (X,Y,Z, Roll)

6 – DELTA: 4 axis, XYZR (X,Y,Z, Roll)

COMMON SHARED scara AS GROUP AxNm = a1 AxNm = a2 AxNm = a3 AxNm = a4 Model = 4

This automatically defines a robot with a SCARA kinematics model. Contrary to the regular groups that need only the axis to be enabled, you must set the robot parameters and configure them. The robot parameters needing to be set differs from robot to robot. For the SCARA robot, these are:

Set all axes with all standard kinematics parameters.

Define the roll-over properties.

Set all user-units factors for the entire group: VFAC, AFAC, JFAC

Set segment lengths and joints orientations for each robotic link.

Set kinematics of regular groups (VELOCITY, ACCELERATION, JERK, etc.)

Set kinematics of Cartesian motions (VTRAN,VROT, etc.)

Issue CONFIGGROUP.

Only after setting all these and successfully executing CONFIGGROUP can the robot be moved. Otherwise, an error is returned, stating that the group is not configured. The important difference between the regular groups (those with default model value 1) and the robot, is the necessity of executing CONFIGGROUP. In robot groups, no motion is allowed before the robot is configured.

Model value automatically defines the default robot world space descriptor. For model 4 (SCARA), the XYZR (x-y-z-roll) world-space is selected. With no robot model defined (model=1), the world-space descriptor is chosen according to the group size:

2-axes: XY

3-axes: XYZ

4-axes: XYZR

In these cases, world-space is identical to joint-space. Each coordinate of the joint-space vector is directly translated into a coordinate of world-space.

In groups with the robot model defined (model > 1), the translation between joint- and world-space is much more complex. Translating joint coordinates into world coordinates is accomplished with TOCART taking both the robot and given joint coordinates (position variable) as input arguments. The output of this is world coordinates corresponding to the given joint position.

The other direction is more complex. It is accomplished with TOJOINT receiving three input arguments: the robot, the given Cartesian point, and the configuration flag.

The configuration flag is used to select between the two translation functions. In most robot models, there is more than one joint coordinate description for the same world-space position. The different robot configurations can produce the same world-space positions with different joint-space values. The robot configurations differ from robot to robot. In SCARA, there are only two configurations: lefty (second joint coordinate is negative) and righty (second joint coordinate is positive).

Cartesian Robots

To make all robot features available to non-robot kinemaitcs (i.e. identity) Cartesian robots are introduced. Declaring such a robot is easy:

Common Shared <name> as group { axnm = <axis name>} model =1 of <robot type>

Where <robot type> is one of the follwing:

XY (“X” and “Y”)

XYZ (“X” , “Y” and “Z”)

XYZR (“X” , “Y” , “Z” and “Roll”)

XYZRP (“X” , “Y” , “Z” , “Roll” and “Pitch”)

XYZYPR (“X” , “Y” , “Z” , “Yaw” “Pitch” and “Roll” )

Interpolation

For groups with robot models (model > 1), there is an additional moving type: MOVES. The movement makes a straight path from the starting position to the given target position in the world space. The straightness is tightly-related to the working space. The same path can be straight in the Cartesian working space (XYZ) but curvy in joint space, and vice versa. MOVES is used solely for groups from type robot and cannot be used in regular groups.

Straight line motion refers to motions that are straight lines in world-space. In groups with no robot model (model=1), all motions produced with MOVES are straight-line motions in joint-space. In regular linearly-dominant groups, most of their axes are linear. As the world-space and joint-space are identical, MOVES executes a straight line in both joint- and world-space. The target position can be given both in world- and joint-space coordinates. The movement differs from joint interpolation (MOVE). Instead of joint-space kinematics parameters used in regular groups, the world-space parameters for velocity, acceleration and jerk are used. These parameters are available in two forms:, one for the translational part of the motion and one for the rotational part (orientation).

When world-space has both position and orientation components, the straight-line motion includes interpolation on both position and orientation. Because these two are intrinsically different objects, two different parameters are needed: one for the translation (pure position interpolation): VELOCITYTRANS, ACCELERATIONTRANS, JERKTRANS; and one for the orientation (rotation interpolation): VELOCITYROT, ACCLERATIONROT, JERKROT. These parameter are used only for Cartesian interpolation (MOVES and CIRCLE). These parameters have no influence on joint interpolated motion (MOVE) because it is not a world-space interpolation.

The two sets of parameters define the straight line motion. Which parameter is dominant for the motion depends on the movement. If most of the movement is in translational position change and the orientation change is much smaller, the translational part is taken. Conversely, the rotational parameters define the movement.

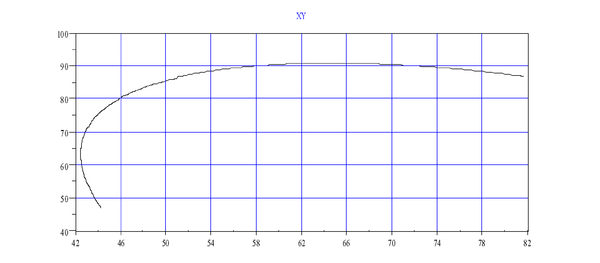

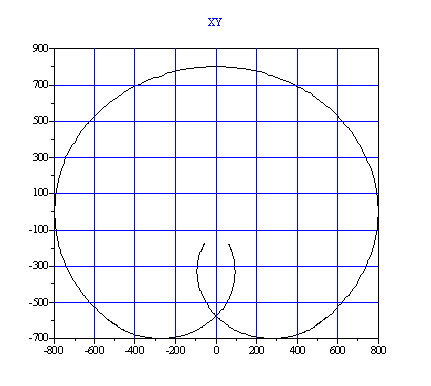

The following graph shows MOVES as seen in joint-space.

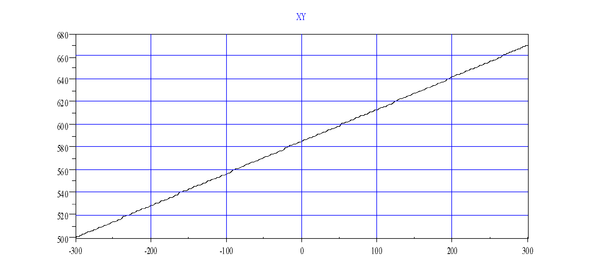

The following graph shows MOVES as seen in world-space.

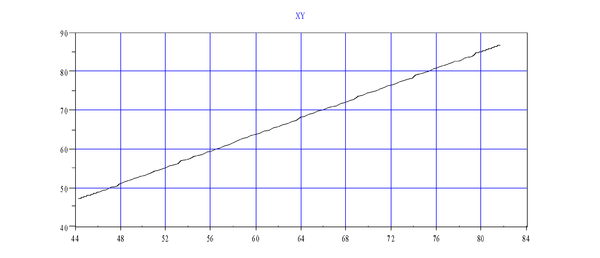

The following graph shows MOVE as seen in joint-space.

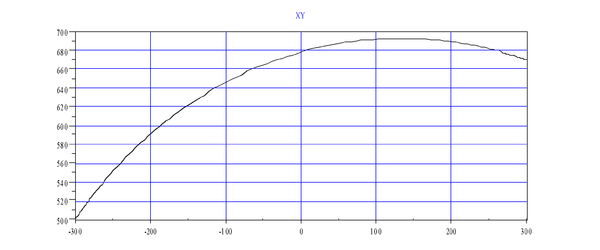

The following graph shows MOVES as seen in world-space.

There are four commands to make point-to-point movement in robot groups. There are two commands to interpolate the motion (MOVE and MOVES) and two commands to define the target point (JOINT and LOCATION). The total combination of these gives four options.

| LOCATION target | JOINT target | |

| Cartesian-Interpolation | MOVES #{400,400,0,0} | MOVES {45,45,0,0} |

| Joint-Interpolation | MOVE #{400,400,0,0} | MOVE {45,45,0,0} |

Contouring

Contouring connects different motions by defining the final velocity for each movement. This way, the motion does not stop at the segment. It is continued with the next motion. This method is applicable in one-axis applications, but has several drawbacks that become more prominent in multi-axis applications:

The angle between the movements' direction must be zero. Otherwise, a jump in velocity occurs.

It is not possible to connect arc with linear segments without a jump in acceleration.

You must calculate the achievable final velocities on each segment to stop after the last segment.

Cartesian Profile

For kinematics parameters of straight-line (MOVES) motion (velocity, acceleration, deceleration), different joint parameters are obtained, depending on where in the robot working space the starting line is positioned. The further from the origin, the smaller joint velocities are obtained. Contrary to that, the closer to the origin the point is, the smaller the inertia and higher the acceleration.

To optimally exploit robot capabilities, execute motions nearer to the origin with smaller Cartesian velocities to avoid exceeding the maximum joint velocity. Movements near the limits of the working space are farther from the robot origin and have higher robot inertia. Lower acceleration must be applied to avoid exceeding the maximum joint values.

You must know at least two values (threshold of arm radius where reduction begins and end point of reduction at straight arm) for all joints. Limits must be considered for the joint. The whole Cartesian path and all Cartesian interpolation types (straight, circular, via) must be considered.

Since joint velocity, acceleration, or jerk values cannot be exceeded, take the minimum of the commanded Cartesian values (VTRAN, ATRAN, DTRAN, JERKTRAN, VROT, AROT, DROT and JERKROT) and account for the values in joint-space (VCRUISE, ACC, DEC, JERK).

Cruise velocity cannot vary. Use a constant cruise value. Leave the principal profile acceleration and deceleration phase as it is. Acceleration and deceleration cannot vary during the constant ACC/DEC phase. Use the highest acceleration in Cartesian space possible that allows constant ACC/DEC phases without exceeding joint values. Acceleration and deceleration may differ, and must be considered separately (mostly in long distance moves where conditions vary widely for start and destination position). The same restrictions apply to JERK.

Acceleration, deceleration and jerk reduction must be calculated and anticipated, depending on payload and arm radius. The parameters for a simple scheme are:

threshold values for payload and arm radius where reduction begins

overall 100% reduction value per robot group

per-joint 100% reduction values

Since payload is static (varying only with tool change), this is easily accomplished in the application. Use the following two mechanisms for Cartesian profiles:

Cartesian Velocity Adaptation (CVA) is according to the direction and position of the movement in the working space. For each path, a point closest to the origin (X=0,Y=0) is found and the Cartesian velocity of the whole motion is reduced according to the values of joint velocities at that point.

Cartesian Acceleration/Deceleration/Jerk Adaptation (CADJA), where values of jerk, acceleration and deceleration are reduced according to the relative distance from the point of origin in reference to the maximum radius of the robot. The reduction (INERTIATHRESHOLD) is active only from a certain distance (radius). The maximum reduction value is defined at the final point (the fully stretched arm). For all points between these two values (INERTIATHRESHOLD = 100%), the reduction value is linearly interpolated. Acceleration is reduced according to the initial point of the movement. Deceleration is reduced according to the final point of the movement. The jerk value is reduced according to the average of the two reduction values (for initial and final point).

Limitations are:

Reduction factors are not allowed for individual axes – only for groups.

The CVA works only for MOVES & PASS-THRUGH .

The CADJA works only for MOVES & PASS-THRUGH. In PASS-THROUGH, only the first and last point are treated.

Both methods work only for SCARA kinematics.

Working Envelope

Robot working space is determined by the position limits of each joint. The working space (all reachable positions) is limited by the working envelope of the robot. From the outer side, it is limited by the arc made rotating the first joint with a fully stretched arm (j2.pcmd=0). This is the maximum radius of reachable points (RMAX). It is an internal value computed each time the robot is configured (CONFIGGROUP). Points given outside this radius are rejected with the error message, Point Too Far.

The other limit is the small circle with the radius (RMIN). This circle is obtained by rotating the first joint with a maximally-folded second joint (not more then 180 degrees). This radius is additionally enlarged by the robot's base size and the attached end-effector mechanism to prevent the robot from colliding with itself. The minimal working envelope radius (RMIN) is available to the user (contrary to RMAX). Danaher Motion recommends setting this value for each application, according to the physical setup of the robot. If a point is given inside RMIN, an error message is returned. For example:

Program

attach

move {j1.pmin,j2.pmin,0,0}

while ismoving

sleep 1

End While

Print "Plotting the workspace"

move {j1.pmin,0,0,0}

move {j1.pmax,0,0,0}

move {j1.pmax,j2.pmax,0,0}

detach

End Program

Robot Configurations

In robot models, there are several joint points representing the same robot end-effector position for each location point. To uniquely select between different joint coordinates, there are configuration flags.

For SCARA kinematics, there is only one configuration flag available: the arm flag. It indicates either lefty (1) (j2.pcmd > 0) or righty (2) (j2.pcmd > 0). A value of 1 (lefty) means that the joint coordinates having a positive second joint are taken to represent the given location. The current configuration of the robot is returned by ARMFBK. The value can be 1 or 2, depending on the position feedback value of the second joint. ARMFBK determines the movement's target position. It can be automatic (0), lefty(1) or righty(2). When a movement with a Cartesian target position is given, the joint coordinates of the target position are selected according to ARMFBK. If it is zero (automatic), the current robot configuration is used (ARMFBK).

PUMA models traditionally use three configuration flags (arm,elbow and wrist – ACMD, ECMD, WCMD).

Another use of configuration flags is in the conversion function, TOJOINT. This function translates the given location point into joint point. It receives two arguments. The first is the location variable and the second is the configuration flag.

POINTS

A point is a new data type used for storing a list of doubles in a variable. The main advantage of points is that you can directly call the whole vector without having to access every element of it. There are two subtypes of the point data type: LOCATION and JOINT. Using both point types in the same expression results in a type mismatch translation error. Type casting between point types requires the usage of special system functions TOJOINT and TOCART.

Declaration

A point must be declared before you can use it. The declaration of points is defined according to the type of robot (XYZR, XYZ, etc.). The MC enables the declaration of point variables, which can be scalar or arrays. Point arrays may have up to 10 dimensions. Point variables are designed to hold a list of 2 to 10 double-type coordinates. A point variable is declared in relation to a robot type. Therefore, declaring a point variable must include the name of a valid robot type. The dimension of the point is the same as the dimension of the type of robot. The syntax is:

(COMMON SHARED|DIM {SHARED}) <variable_name> AS JOINT OF <robot_type>(COMMON SHARED|DIM {SHARED}) <variable_name> AS LOCATION OF <robot_type>

<robot_type> can be:

XYZR – Three cartesian axes + rollXY – two axes XY tableXYZ – three axes XYZ system

For example:

Common Shared JointXYZ As Joint Of XYZ Common Shared JointXYZR As Joint Of XYZR Common Shared LocXYZ As Location Of XYZ JointXYZ = LocXYZ --> Error – type mismatch

Variables

Two new variable types are defined for point variables in the translator: LOCATION and JOINT. For the translator, a point variable differs from any other type of variable (Long, Double, etc.) only by its type. A point variable is inserted to the expression tree as a variable leaf. The variable leaf retains data related to the point variable, including its context (system, program or local), its offset (taken from the symbol table), and its type (LOCATION or JOINT, also taken from the symbol table).

Declaration

When declaring a point variable, data corresponding to this variable is entered into the correct symbol table (depending on whether it is a system variable, a program variable, or a local variable). A point variable is defined in the symbol table by its name, its type (LOCATION or JOINT) and an offset of the data segment. Each offset of the data segment corresponds to the address of the point variable. The robot type string is sent to a special function that gives the robot-type value and the number of coordinates.

Constant Points

Constant points are location or joint vectors with an undefined robot type. The constant point’s subtype is defined by the shape of its brackets (#{ } for location, { } for joint). In the translator, each of these two vector types is considered an expression. Each expression-related command and manipulation (such as print commands, mathematical operators, etc.) can be applied for the joint and location vectors.

While executing a vector expression, each vector element is pushed separately into the stack as a double type expression (by executing the left side of the JOINT or LOCATION node). Long type vector elements are converted to double type expressions (in the coordinate node) after the execution of the expression at the right side of each coordinate node).

Execution of the right side of the JOINT or LOCATION node results in pushing the number of the vector elements into the stack (as a long type constant). The point’s subtype (determined by the shape of the vector’s brackets) is pushed to the stack (as a long type constant) by executing the third side of the JOINT/LOCATION node.

Vectors

Vectors are actually constant points, at which a list of 2 to 10 coordinates is written between curly brackets {}. In location vectors, the curly brackets are preceded by the # sign. A coordinate can be any type of expression (constant, variable, mathematical expression, function call, etc.) of long or double type. Long type coordinates are automatically converted to doubles. Unlike point variables, vectors are not related to robot types, and characterized merely by their size (number of coordinates).

{<expression_1>, …, <expression_n>} ‘ Joint vector

#{<expression_1>, …, <expression_n>} ‘ Location vector

Point variables and vectors appearing in the same expression must match in type (joint or location) and size.

Common Shared JointXYZ As Joint Of XYZ

JointXYZ = #{1.5, 2.8, 3} Error – type mismatch

PRINT {20, 6.7, 23} + #{8.43, 2, 0} --> Error – type mismatch

JointXYZ = {2, 6} Error – size mismatch

PRINT {20, 6.7, 23} - {5, 4, 22.9, 31} --> Error – size mismatch

Properties

Some group properties are points. There are several read-only properties of joint- (VELOCITYFEEDBACK, POSITIONCOMMAND, DEST_JOINT), and location-type (DEST, HERE, SETPOINT). There are also some location-type read-write properties, like TOOL, BASE, etc.

As in point variables, the robot type also characterizes point properties.Point properties appearing in expressions in a mixture with other points must match in type and robot type to point properties and variables, or in type and size to vectors.

Common Shared SCARA As Group Axnm = A1 Axnm = A2 Axnm = A3 Axnm = A4 Model = 4

Common Shared PointXYZR As Joint Of XYZR

Dim Shared PointXYZ As Joint Of XYZ

PointXYZR = SCARA.SetPoint

--> Error – type mismatch (Setpoint returns a location)

PointXYZ = SCARA.VelocityFeedback --> Error – robot type mismatch

SCARA.Base = #{56.5, -104.7, -90.5} --> Error – size mismatch

Point Dimension

You do not define the size of the vector data type at the declaration of it, but you define the type of robot related to the point. This gives the point a dimension.

Point Assignment

Point assignment uses the following syntax:

<variable_name> = (<expr1>,<expr2>,<expr3>,…,<exprn>)() = #{} for location() = {} for joint

The expression can be a constant or other vector variable of the same robot type, but the size of the right side of the expression must equal the left side. If you try to assign a point with a point of other robot type, an error is received.

Single Coordinate Point Assignment

The syntax for assigning a single coordinate of a point is:

<variable_name>{<expression>} = <expression>

Point Query

The syntax for querying a point is:

?<variable_name>

Single Coordinate Point Query

The syntax for querying a single coordinate of a point is:

?<variable_name>{<expression>}

Example1:

Common shared P1 as location of XYZR 'declaration of a vector (global)

P1 = #{1,2,3,4} 'assign the whole vector

P1 = #{1,2} 'return a translation error

?P1 'read the whole vector

?P1{2} 'read the second coordinate of the vector

Example2:

Common shared P2[5] as location XYZ 'declare a global array of vectors

P2[1] = #{1,2,3} 'assign the whole vector

P2[2] = #{5,2} 'return a translation error

?P2[1] 'read the whole vector

?P2[2]{2} 'read the second value of the vector

Operators

Like any other data type, you can use operators for points. The system only defines the equal operator (plus, minus, multiplication and division). Operations between points can only be performed between points of the same type and robot type (or size). All operations can also be performed between points and long or double type expressions.

Assignment

Point variables and read-write properties can be assigned by point variables, vectors and point properties compatible in type and size (or robot type).

Query

Point variables, properties and vectors return a value, so they can all be queried through printing or assignment into a compatible point variable or read-write property.

Common Shared SCARA As Group Axnm = A1 Axnm = A2 Axnm = A3 Axnm = A4 Model = 4

Common Shared PointVar1 As Joint Of XYZR

Dim Shared PointVar2 As Joint Of XYZ

Dim PointArr[4] As Joint Of XYZR

PointVar1 = PointArr[2]

PointVar2 = {23.4, 60, 42}

PointArr[1] = SCARA.PositionCommand

SCARA.Tool = #{10, 20,30, 0}

PRINT PointVar2, SCARA.Tool, {100.3, 20}

--> {23.4 , 60 , 42} #{10 , 20 , 30 , 0} {100.3 , 20}

Plus

The point plus operator is used like any other data type. It adds each element of the first point with each element of the second point. The result is a point.

?(1,2)+(2,4) --> (3,6)

Minus

The point minus operator is used like any other data type. It subtracts each element of the first point with each element of the second point. The result is a point.

?(1,2)-(2,4) --> (-1,-2)

Multiplication

The point multiplication operator is used like any other data type. It multiplies each element of the first point with a number. You can only multiply a point with a single number (one-dimensional number). The result is a point.

?2*(2,4) --> (4,8)

Division

The point division operator is used like any other data type. It divides each element of the first point with a number. You can only divide a point with a single number (one-dimensional number). The result is a point.

?(2,4)/2 --> (1,2) ?2/(2,4) --> (1,0,5)

Compound (:)

Is an operator specific for points, which should be operated between two locations of the same size (or robot type).

? #{-56.5 , -104.7 , 89.5} : #{ 0.0, -104.7 , -0.5}

--> #{-56.5 , -209.4 , 89}

Limitations

MOD (modulus), ^ (power), logic and bitwise operators cannot be used for points.

Points cannot be used as condition in flow control statements and event definitions.

Points cannot be recorded.

Points in Functions

Point variables can be passed to functions and subroutines both by reference and by value. An entire array of points can also be passed (by reference) to a function or subroutine. On the other hand, point properties and vectors can only be passed by value. Points can also serve as return values of functions. However, the point type and size (or robot type) of an argument or a return value must match function declaration.

Passing By Value And Reference

A point can be passed by value and by reference like any other data type. For example:

Program

Dim p1 as joint of XYZR

Call Sub1(P1)

?p1

End program

Sub Sub1(X as joint of XYZR)

X = {1,2,3,4}

End Sub

This program assigns P1 to {1, 2, 3, 4} and prints {1, 2, 3, 4} as output. When a point is passed by reference or value, you can only pass a point of the same robot type to X. Otherwise, you receive a translation error.

Example1:

Program

Dim p1 as location of XYZR

Call Sub1(P1 --> TRANSLATION ERROR !!!

?p1

End program

Sub Sub1(X as location of XYZ)

X = #{1,2,3,4}

End Sub

Example2:

Program

Dim p1 as joint of XYZR

Call Sub1(P1) --> TRANSLATION ERROR !!!

?p1

End program

Sub Sub1 (ByVal X as joint of XYZ)

X = {1,2,3,4}

End Sub

Returning Point From Function

A function can return a point variable like any other data type. For example:

Dim A as location of XYZR

Program

Move G1 MyFunc(1) vcruise=299

--> this will be OK if G1 is of XYZR robot type.

End Program

Function MyFunc(i1 as long) as location of XYZR

MyFunc = #{1,2,3,4}

End Function

Motion Commands

Some motion commands use point nodal parameters when applied on groups. For example: CIRCLE, MOVE and MOVES.

Some nodal parameters can be assigned with both point types (LOCATION and JOINT), like CIRCLECENTER, CIRCLEPOINT and the target positions of MOVE and MOVES. Other nodal parameters can accept only location points, like TOOL, BASE, etc. Assign all nodal parameters with points compatible in robot type or size to the group.

Common Shared SCARA As Group Axnm = A1 Axnm = A2 Axnm = A3 Axnm = A4 Model = 4

Common Shared JointXYZ As Joint Of XYZ

MOVE SCARA JointXYZ --> Error – robot type mismatch

CIRCLE SCARA Angle = 180 CircleCenter = #{350, 500, -80}

--> Error – size mismatch

MOVES SCARA #{-22, 503.8, -8.3, 149} Base = SCARA.Dest_Joint

--> Error – type mismatch

Analog Behavior

Because a point is a new data type, it has all the functionality of the other data types like saving the point to a file, watching points, deleting points.

Point As An Expression

With the new point data type, points properties can be stored as a point or can be compared as a point. For example:

Dim A as Joint of XYZR

A = {1,2,3,4}

A = G1.Pcmd

A = G2.Pcmd --> returns a translation error if G2 is not of XYZR type.

Functions

The following functions are defined:

<XYZR location> = TOCart (<group>, <XYZR JOINT>) <XYZR Joint> = ToJoint(<group>,<XYZR LOCATION>,<configuration-flag:integer>) <double> distl(<location>,<location>) Distance between points (length). <double> distr(<location>,<location>) Distance between points (angle).

Where for TOJOINT instruction the number and type of configuration flags depend on each robot type. Note that robot properties ARMCMD, ECMD, WCMD have all three values(0,1,2) where 0 is reserved for AUTO option. The configuration bits hovewer have only two values (0,1).

for SCARA robot : Arm ( Bit 0): value = 0 - Lefty(armcd = 1)value = 1- Righty(armcmd = 2)

for PUMA robot : Arm ( Bit 0): value = 0 - Lefty(armcd = 1) value = 1 - Righty(armcmd = 2)

Elbow ( Bit 1):value = 0 - Below(ecmd = 1) value = 1 - Above(ecmd = 2)

Wrist ( Bit 2): value = 0 - Noflip (wcmd = 1) value = 1 - Flip (wcmd = 2)

for TRAVERSEARM robot: Arm ( Bit 0): value = 0 - Lefty(armcd = 1)value = 1 - Righty(armcmd = 2)

for DELTA, SCISSORS, … and other robots that have no configuration flags these fileds are not used.

The configuration flag argument of the tojoint is defined as:

SAVE/LOAD

Each global variable can be stored in a file. The variable and its value are stored in same syntax as it is defined in the program. You can select a data-type to be stored. If a data-type is selected, the SAVE command stores only global variables of that data type. If file with same name already exist its extension is renamed to *.bak and new file is created. Loading the file overwrites the values of the saved global variables. You can save all the points related to some type of robot. For example:

SAVE file = "Myfile.prg" type = location robottype = xyzr SAVE file = "Myfile.prg" type = all LOAD Myfile.prg

Group Point Properties

Following modal-only and read-only group properties of the point data-type exist:

| DEST | DEST_JOINT | Target point of the movement. |

| START | START_JOINT | Starting point of the movement. |

| HERE | POSITIONFEEDBACK or PFB | Actual point of the robot (feedback). |

| SETPOINT | POSITIONCOMMAND or PCMD | Actual point of the robot (group). |

Single Element Assignment

Syntax for assigning a single element of a structure:

<variable_name>-><structure element> =<expression>

In Functions

Structures can be passed to functions and subroutines both by reference and by value. Also, an entire array of structures can be passed (by reference) to a function or subroutine. Structures can also serve as returned values of functions. However, the structure type of an argument or a returned value must match function declaration.

Dim Shared ARG1 As Type_1 Dim Shared ARR_ARG[4][5] As Type_1 Dim Shared ARG2 As Type_2 FUNCTION MyStructFunc(BYVAL Par1 AS Type_1, Par2 AS Type_2) AS Type_1 … MyStructFunc = Par2 -> Error - structure type mismatch MyStructFunc = Par1 -> Structure types match END FUNCTION SUB MySub(Arr_Par[*][*] AS Type_1) … END SUB ARR_ARG[2][3] = MyStructFunc(ARG1, ARG2) -> Structure types match ARR_ARG[2][3] = MyStructFunc(ARG1, ARG1) -> Error - structure type mismatch CALL MySub(ARR_ARG)

or

Common Shared ST As STRUCT

Common Shared LongVar As Long

FUNCTION MyFunc(BYVAL Par1 AS LONG, Par2 AS LONG) AS STRUCT

…

MyFunc->LongElm2 = 10

MyFunc->JointElm = {12.3, 5, 43.29}

END FUNCTION

FUNCTION NoParamFunc AS STRUCT

…

END FUNCTION

ST = MyFunc(ST->LongElm1, LongVar)

ST = MyFunc(ST->LongElm1, ST->LongElm2)

-> Error – structure element passed by reference

? MyFunc(ST->LongElm1, LongVar)->LongElm2

-> Error – addressed through function call

LongVar = NoParamFunc->LongElm2

-> Error – addressed through function call

A function can return a structure variable like any other data type. For example:

Dim Shared A as X Program Dim S1 as X S1 = MyFunc(1) End Program Function MyFunc(i1 as long) as X MyFunc->Type = 1 End Function

Query

You cannot query a whole structure or you receive a translation error.

?<variable_name> - gives a translation error

Single Element Query

Syntax for querying a single element of a structure:

?<variable_name>-><structure element>

For example:

Common shared s1 as X 'declaration of a default structure S1->.Type =1 S1->Length =2 ?S1 'Translation Error ?S1->Type

Operators

You cannot use operators with structures. It is possible to use operators for the single elements of the structure.

Pass Structure

A structure can be passed by value and reference like any other data type.

Example1

Program Dim s1 as X Call Sub1(S1) ?S1->Type End program Sub Sub1(X as X) X ->Type= 1 End Sub

Example2

Program Dim s1 as X Call Sub1(S1) ?S1->Type End program Sub Sub1(X as X) X ->Type= 1 End Sub

Limitations

A whole structure cannot be printed.

Mathematical, logic and bitwise operators cannot be used for whole structures.

A whole structure cannot be used as a condition in flow control statements and event definitions.

A whole structure cannot be recorded.

For example:

Common Shared VAR1 As STRUCT Common Shared VAR2 As STRUCT PRINT VAR1 -> Error VAR2 = VAR1 * 100 -> Error IF VAR2 > VAR1 THEN -> Error WHILE VAR2 -> Error