AXY:MC Operational Modes

| NOTE | |

| This topic is still not implemented, here is as a spec for further discussion only |

Loop Types

The AMCS system supports the next main control loop types:

- Position Control with standard feedback. (OPMODE 5)

- Position Control with Dual-feedback (OPMODE 5)

- Position Loop Feedback from external feedback (load sensor) . (OPMODE 5)

- Digital Velocity Control with standard feedback (motor sensor). (OPMODE 0)

-

Analog Velocity Control. (OPMODE 1) - Digital Torque. (OPMODE 2)

-

Analog Torque. (OPMODE 3)

The controller sends position , velocity and torque commands each update cycle. The operation of the controller is hardly affected by the loop selection. The loop selection is made in the controller.

Position Loop

Position loop is the standard operating mode of the AMCS system. Position Loop is available in the digital position mode only (OPMODE 5). The digital position mode is default for AMCS and has been set automatically.

Position ERROR WITH Proportional Position Loop

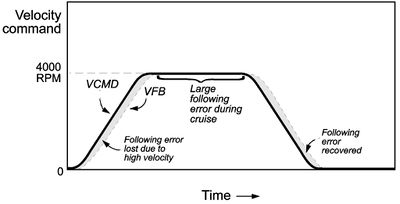

The proportional position loop is the simplest position loop. The velocity command is proportional to the following error. Large velocity commands need large following error limits. The constant of proportionality is GP (position loop gain). At first, this may seem confusing. Actually, it just means that for each count of position error, a command of GP RPM is given.The following error for acceleration with a typical proportional loop is shown below.

Reducing Position Error

Position error generated during a move is often called “following error” because it measures how well the motor follows the command. Reducing the following error is equivalent to following the command more closely, which normally is desirable. Commonly, you will set GP to be large, which reduces following error because the higher gain means it takes less position error to generate the same velocity command. There is a limit though, because if GP gets too large, the position loop becomes unstable. After GP is as large as possible, what else can you do to reduce position error?

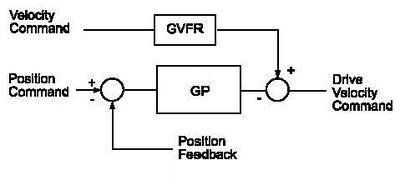

One technique to reduce following error is to add a feed-forward term to the velocity loop. This allows you to generate velocity commands with a combination of the profile velocity command and position error, rather than relying wholly on position error. A position loop with feed-forward is shown in the following figure.

In this case, you can reduce following error by raising the gain GVFR.

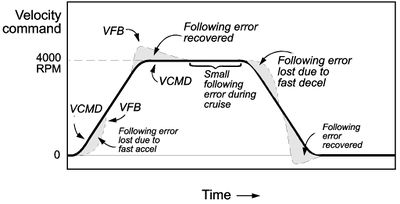

When GVFR is at full scale (GVFR =1), the following error at steady-state is reduced to zero. The only following error is generated during transients. The effect of full feed-forward on following error is shown in the following figure.

The benefit of full feed-forward is that it eliminates steady-state following error. The drawback is that the system overshoots when subjected to acceleration or deceleration. In some cases, this is not an issue because the system may always transition smoothly, or some overshoot may be acceptable. However, in many cases of full feed-forward is not acceptable. In these cases, you can reduce the feed-forward term to reduce overshoot. The larger the feed-forward gain, the greater reduction you will see in steady-state following error. Most systems can tolerate the overshoot generated by feed-forward gains of 50%.

OPMODE

This command allows you to change the drive operation mode.

Short form

None

Syntax

OpMode <value>

?OpMode'

Range

0 , 1 , 2 , 3 and 5

0 : Digital velocity opmode

1 : Analog velocity

2 : Digital torque

3 : Analog torque

5 : External position used as the digital position, the regular position mode

Units

NA

Default

5

Scope

Configuration, Task, Terminal

Limitations

Read/Write: R/W in CP4, Axis must be disabled.

Examples

OpMode 2

DIGITALTORQUE

Executes Digital Torque command ,similar to Jog command with automatic scaling of the profiler-velocity to torque. Automatically causes the AMCS to enter digital torque mode. <Torque Value> Value of the target torque in mA if greater then TMAX then the later value will be used , sending a note to the user.

TimeToTorque – time needed to reach the target torque value from the initial torque value.

TimeTorque – duration of the torque command, if set to –1 (default) endless torque command. (Same as TimeJog)

Type<Torque Value> : Double

<TimeToTorque>: Long

<TimeTorque>: - Long

Short form

DTorque

Syntax

DigitalTorque <Torque Value> {TimeToTorque=<time>} {<TimeTorque>=<time>} {<StartType=<starttype value>}

Range

- ±DIPEAK

Units

<Torque Value> : MilliAmperes

<TimeToTorque>: MSec

<TimeTorque>: MSec

Limitations

DigitalTorque OpMode.The axis must be attached to that task either implicitly (if no other task is accessing the axis) or explicitly using the “ATTACH” command.

Examples

DigitalTorque trq StartType=Immediate

TIMETOTORQUE

Defines the time needed to change the torque from an initial value to the value given in the DigitalTorque command.

Syntax

TimeToTorque=<time> DTorque <Torque Value> {TimeToTorque=<time>}

Type

Long

Range

1 to MaxLong

Units

Milliseconds

Scope

Task, Terminal

Limitations

Modal/Nodal .To set the value within a task, the axis must be attached to that task either implicitly (if no other task is accessing the axis) or explicitly using the “ATTACH” command.

Examples

?TimeToTorque

DigitalTorque 100 TimeToTorque = 1000

TIMETORQUE

Duration of the torque command .Time when the deceleration (torque decrease towards zero) is started, counting from the end of the torque increase. If set to –1 (default) endless torque command .

Syntax

DTorque <Torque Value> {TimeTorque=<time>}

Type

Long

Range

-1 , 0 to MaxLong

Units

Milliseconds

Default

1

Scope

Task, Terminal

Limitations

Nodal only.To set the value within a task, the axis must be attached to that task either implicitly (if no other task is accessing the axis) or explicitly using the “ATTACH” command.

Examples

DigitalTorque 100 TimeTorque = 1000