How to setup Position Error Delay

How to SetUp Position Error Delay

First Step

- set PEDEL to 1 (minimum value)

- set high value in PeMax

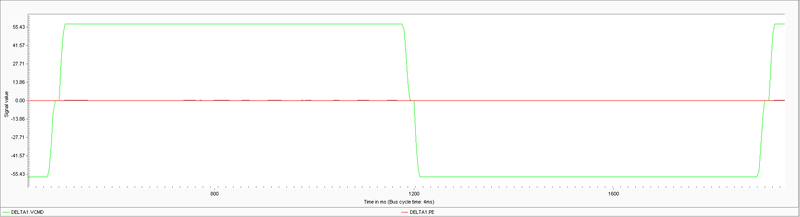

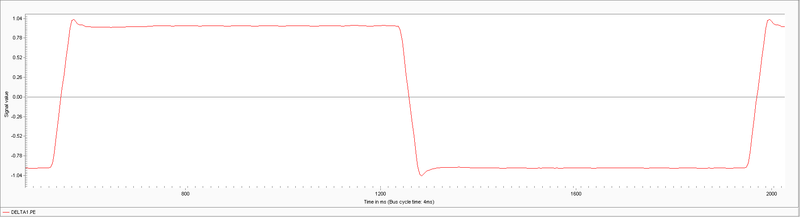

- Run the axis back and forth and record PE and VCMD as :

Command Velocity recordings

Position Error recordings

Compute PEDEL as PE/VCMD, in this case it will be:

PE/VCMD = 0.94/57.74*1000 = 16.2 ms

Taking into account the used value of PEDEL (1) and the sampling time of 4ms we get the new PEDEL value of 5, e.i. PEDEL = 1 + 4 = 5

Second Step

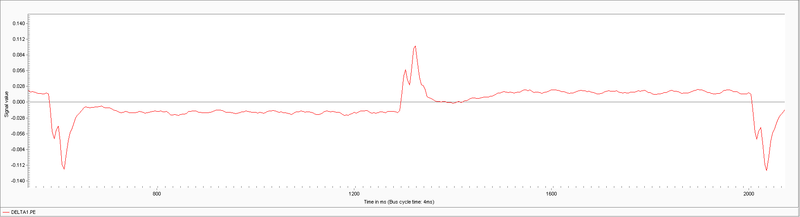

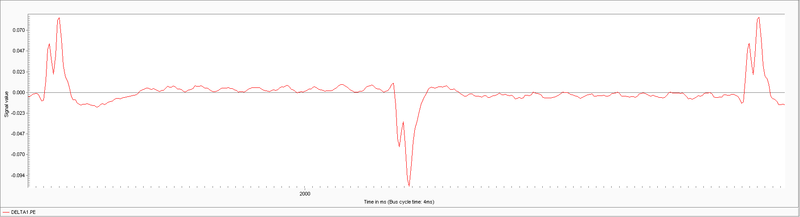

Change the PEDEL(5) to the integer value estimated before and run the test again:

again estimate the error:

PE/VCMD = 0.18/57.74*1000 = 0.317 ms

| IMPORTANT | |

| This means the non-integer communication delay of the drive is 317 micro-seconds. |

which is in units of one sample equal:

317/4000 = 0.078

So setting PEDEL to 5.078 we get:

Example File

PDLtune.prg

'

common shared Ax as generic Axis

program

dim i as long

Ax = A1

with Ax

Attach

Pedel = 1 ' first run

Pedel = 1 + round(1.68 / 100.0 * 1000.0 / (bus[0].cycleTime/1000)) ' 2nd run. extracted from recordings

Pedel = Pedel + 0.075 / 100.0 * 1000.0 / (bus[0].cycleTime/1000) ' 3rd run. extracted from recordings

PeMax = 10

En=1

Sleep 100

Move 0 Vcruise=100 Abs=TRUE

call waitMotion

Record ax_PE.rec 100000 Gap=1 RecData = Ax.Pe, Ax.Vcmd

RecordOn

Sleep 100

for i = 1 to 3

Move 100 Vcruise=100 Abs=TRUE

call waitMotion

Sleep 100

Move 0 Vcruise=100 Abs=TRUE

call waitMotion

Sleep 100

next

RecordClose

En=FALSE

Sleep 100

PeMax = 0.1

Detach

end with

terminate program

sub waitMotion

while Ax.IsMoving

Sleep 1

end while

end sub