Axis Setup Procedure

The steps below explain how to create and define an axis in the softMC controller.

The following are required:

- Running softMC (actual or simulated)

- User interface (ControlStudio)

Contents

- 1 Step 1: Declare Axis

- 2 Step 2: Setting Meaningful Axis Name

- 3 Step 3: Preparing General Axis Setup

- 4 Step 4: Position Units Definition

- 5 Step 5: Moving Direction

- 6 Step 6: Velocity, Acceleration, Jerk Units

- 7 Step 7: Units Summary

- 8 Step 8: Position Limits

- 9 Step 9: Motion Bus Units Setup

- 10 Step 10: Motion Parameters

- 11 Step 11: Safety Parameters

- 12 Step 12: Smoothness

- 13 Step 13: Axis Setup Complete Example - the SetAxis Subroutine

- 14 Step 14: Motion-Bus EtherCAT Example

- 15 Step 15: Extra - Dynamic Model

Step 1: Declare Axis

In the first line of CONFIG.PRG file write the number of axes that will be in use:

Sys.Naxes = <number> … Program … End Program

Send this file to softMC and run it by issuing these two lines from terminal window:

send config.prg reset all

Now you have your axes defined, it is easily to check issuing this command from terminal window:

->?axislist A1,A2,A3,A4,A5,A6,A7,A8,A9,A10,A11,A12,A13,A14,A15,A16,A17

Step 2: Setting Meaningful Axis Name

System default axis names are not very user friendly (a1,a2,a3, etc.). It is a good practice to give them more meaningful names. This is done in CONFIG.PRG file only, by assigning a new name to each axis (no double-quotes) to <axis>.AxisName property.

Sys.Naxes = <number> … Program a1.AxisName = Xaxis a2.AxisName = Lift … End Program

Step 3: Preparing General Axis Setup

To set up system axes, a setup program must be prepared. Let’s call it SETUP.PRG.</br> It is important to know:

- To access (write to) an axis property, the axis needs to be attached.

- For some properties, the axis needs to be disabled

SETUP.PRG

Program Call SetAxis(a1) Call SetAxis(a2) … End Program Sub SetAxis(ax as generic axis) With ax Attach En = 0 … <stuff goes here> … Detach End With End Sub

Step 4: Position Units Definition

<axis>.PositionFactor defines the position units that will be used in all position variables of the specified axis (pcmd, pfb, etc.). It consists of:

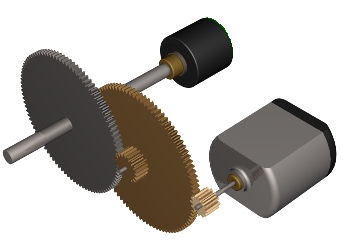

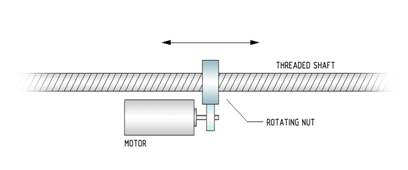

- Motor encoder resolution seen through the motion bus (See EtherCAT, SERCOS, CanOPEN). How many counts are there in one motor revolution - stored in pos_units global variable (for each axis differently).

- Gear ratio (M:N) and/or the pitch of the linear screw (mm/rev).

- Rotary axes:

- For position in degrees PositionFactor is:PFAC = Pos_Units *(M/N)/360

- Linear axes:

- For position in millimeters PositionFactor is:PFAC = Pos_Units)/MPITCH

See Motion Bus setup for pos_units and MPITCH setup

Step 5: Moving Direction

Positive direction of drive's position increments does not have to match the desired positive direction of user axis (Upwards, Left-Right, Counterclockwise). Therefore <axis>.direction flag is to be used:

<axis>.Direction = {1|-1}

Value of -1 indicates direction inversion.

Step 6: Velocity, Acceleration, Jerk Units

Velocity/acceleration/jerk units do not have to match position units. The user may select the units. For all the derivative units (velocity, acceleration, jerk), the default time scale is in milliseconds; therefore scaling is needed.

To use position units per second for velocity the following must be defined:

<axis>.VelocityFactor = <axis>.PositionFactor/1000

In this case if the user sets the position in millimeters the velocity will be mm/sec

To define velocity in RPM of the motor:

<axis>.VelocityFactor = Pos_Units /1000/60

Acceleration and jerk units are the same; their default values are expressed in velocity and acceleration units per milliseconds. Thus, in order to set them per seconds, they need to be set as:

<axis>.AccelerationFactor = <axis>. VelocityFactor /1000 <axis>.JerkFactor = <axis>. AccelerationFactor /1000

Step 7: Units Summary

Position, velocity, acceleration and jerk units are set by:

<axis>.PositionFactor = … <axis>.Direction = … <axis>.VelocityFactor = … <axis>.AccelerationFactor = … <axis>.JerkFactor = …

Step 8: Position Limits

Setting position range of an axis. Setting maximum position:

<axis>.Pmax = … and enabling /disabling it: <axis>.PmaxEn = {0|1}

Setting minimum position:

<axis>.Pmin = … and enabling /disabling it: <axis>.PminEn = {0|1}

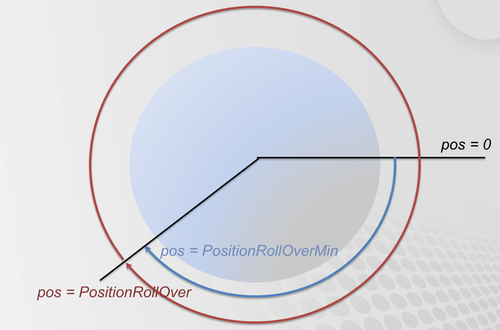

Setting the axis type:

<axis>.AxisType = 0 ‘ For linear axes <axis>.AxisType = 1 ‘ For rotary axes

For rotary axes rollover can be defined: Enabling/Disabling it:

<axis>.PositionRollOverEnable = {0|1}

Setting the whole range:

<axis>. PositionRollOver

Setting the low value:

<axis>. PositionRollOverMin

Note: If the enable flag is not set, the corresponding value does not need to be set.

Step 9: Motion Bus Units Setup

Depending on the type of motion bus (EtherCAT, SERCOS, CANopen) and drive used, several parameters are available for the user to adjust (but are not necessarily needed):

If micro-interpolation is turned on in the drive, the velocity sent to drive must be properly scaled; this is done with (for counts per ms):

<axis>.MotionBusVelocityScale = 0 <axis>.MotionBusVelocityBase = 1

If a limited drive’s position range is used (other then integer 32 bits):

<axis>.CountMin = <drive min position value> <axis>.CountMax = <drive max position value>

Step 10: Motion Parameters

Motion parameters are grouped into velocity, acceleration and jerk values. All have maximum values for overall limitations, and motion-default values that are used when motion is executed.

| Motion default value is: | <axis>.VelocityCruise |

Velocity is set according to maximum axis physical limit (drives/motor capabilities and mechanical limitations):

<axis>.Vmax

| Motion default values are: | <axis>.Acceleration <axis>.Deceleration |

Acceleration is set according to maximum axis physical limits (Max drive/motor current, axis load) in user units:

<axis>.Amax <axis>.Dmax

| Motion default value is: | <axis>.Jerk |

Jerk is the third time-derivation of position, if smooth profiles are used it needs to be defined a good rule of thumb is to set J=BW*A, where J – jerk, A – acceleration, BW- control Bandwidth (Hz).

<axis>.JerkMax

Step 11: Safety Parameters

Maximum allowed position error (PE). PE is defined as a difference between the position command and position feedback. Due to communication delay of the motion bus and processing time of the drive (micro-interpolation) position command of the several samples before the current is compared to the currently obtained position feedback of the drive:

<axis>.PositionErrorMax – max allowed position error during in user units. <axis>.PositionErrorDelay – number of samples used for delay computation.

Velocity (Runaway) Protection, the feedback velocity of the motor is checked every sample (recommended to be set to 120% of the <axis>.VelocityMax)

<axis>.VelocityOverSpeed

Sanity Threshold, as a final protection against unintentional jumps (recommended to be set to 1000% of <axis>.VelocityMax):

<axis>.VelocitySafetyLimit

Torque Error – only if axis dynamic model is turned on

<axis>.TorqueMaxError

Step 12: Smoothness

Different profile types are available, ranging from very smooth S-curves (Acceleration Trapeze, Sine Acceleration) to less smooth but faster Velocity Trapeze, to totally edgy profiles (Constant Velocity) by setting these two parameters:

- <axis>.Smooth defined automatic (0-100) or manual smoothing (-1)

- <axis>.PrfType specifies profile more precisely (Velocity Trapeze, Acceleration Trapeze, Sine Acceleration)

Step 13: Axis Setup Complete Example - the SetAxis Subroutine

sub SetRotAxis(ax as generic axis, byval minval as double , byval maxval as double)

with ax

attach

En = 0

AxisType = 1

PositionFactor = pos_unit/360

VelocityFactor = PositionFactor /1000

AccelerationFactor = VelocityFactor /1000

Jerkfactor = AccelerationFactor /1000

VelocityMax = 1000

AccelerationMax = 10000

DecelerationMax= 10000

JerkMax = 20*amax

VelocityCruise = 0.5*VelocityMax

Acceleration = AccelerationMax

Deceleration = DecelerationMax

Jerk = JerkMax

PrfType = -1

Smooth = -1

VelocityOverspeed = 1.2*VelocityMax

VelocitySafetyLimit = 10*VelocityMax

PositionErrorDelay = 2

PositionErrorMax = 1

PositionMax = maxval

PositionMin = minval

PositionMaxEn = 1

PositionMinEn = 1

PositionRolloverEnable = 0

detach

end with

end sub

Step 14: Motion-Bus EtherCAT Example

Position Units

- First read the motor encoder resolution (MENCRES – SDO:0x20F1:0)

- MENCRES = EC_SDO_READ(<addr>,0x20f1,0)

Then set (value of 1) the configured number of motor shaft revolutions and number of driving shaft revolutions. The gear ratio is calculated by the following:

- Fieldbus CANopen Gear Motor Shaft Scaling (FBGMS – SDO0x2091:0)

- Fieldbus CANopen Gear Driving Shaft Scaling (FBGDS – SDO0x2091:1)

- gear ratio = FBGMS / FBGDS

Step 15: Extra - Dynamic Model

Torque Scaling

- <axis>.TorqueFactor – according to the Motor KT parameter

Limits

- <axis>.TorqueMax – maximum motor torque

Dynamic Model Parameters

- axis.DYNAMICMODEL[..] = <…>