Difference between revisions of "Cut To Length (Punching) Application"

| Line 1: | Line 1: | ||

| − | = | + | {{Languages}} |

| − | + | = 简介 = | |

| + | 偏心冲床(曲柄压力机)正在由凸轮到轮的角位置的伺服驱动的进给装置进给。 轮位置是由被连接到驱动器作为外部位置信号(PEXT)的外部反馈装置(旋转变压器,编码器等)进行测定。 | ||

| − | = | + | = 应用图 = |

[[File:cut2len1.png]] | [[File:cut2len1.png]] | ||

| − | + | 轮的角位置是在其运行期间连续增加的主源信号。 在轮的每一圈,在一个起始和终止角度值之间进给轴应该停止。 | |

| − | = | + | = 运动曲线 = |

| − | + | 进给轴的运行曲线看起来像: | |

[[File:cut2len2.png]] | [[File:cut2len2.png]] | ||

| − | + | 构建此应用程序的主要任务是根据以下参数设计凸轮: | |

| − | • | + | • 轮转角,轮转一整圈所需的pext值。 |

| − | • | + | • 起始角度,冲孔开始时的轮的角度。 |

| − | • | + | • 终止角度,材料移动时轮转过角度或冲孔结束时的轮的角度。 |

| − | • | + | • 切割长度,在终止角度到下一个起始角度从轴位置的距离。 |

| − | • | + | • 从轴的最大加速度和速度,在凸轮运动过程中不能超过这些值。 |

| − | + | 另外一个限制是决定采用速度梯形曲线来进行从动。 可以采用另一个运动曲线,但方程式将不同。 | |

| − | + | 假设轮速度是恒定的,对于计算而言是已知的。 现在,要从给定的A,L,T值计算运动曲线,请参见示例末尾的附录。 | |

| − | = | + | = 程序 = |

<syntaxhighlight lang="vb"> | <syntaxhighlight lang="vb"> | ||

common shared c1 as cam | common shared c1 as cam | ||

| Line 170: | Line 171: | ||

''' | ''' | ||

| − | = | + | = 记录曲线 = |

| − | + | 主轮旋转两圈(切割长度20 mm): | |

[[File:cut2len4.PNG]] | [[File:cut2len4.PNG]] | ||

| − | + | 长度35mm,接近三角形曲线: | |

[[File:cut2len5.png]] | [[File:cut2len5.png]] | ||

| − | = | + | = 用已知的A,L,T计算速度曲线 = |

[[File:cut2len3.PNG]] | [[File:cut2len3.PNG]] | ||

Revision as of 02:29, 17 July 2017

| Language: | [[::Cut To Length (Punching) Application|English]] • [[::Cut To Length (Punching) Application/zh-hans|中文(简体)]] |

|---|

简介

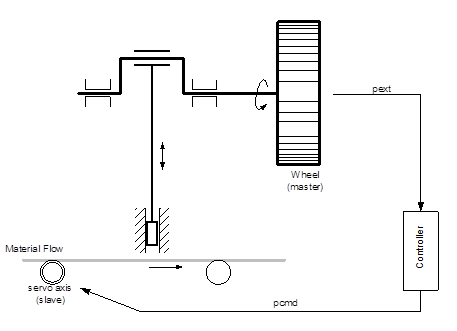

偏心冲床(曲柄压力机)正在由凸轮到轮的角位置的伺服驱动的进给装置进给。 轮位置是由被连接到驱动器作为外部位置信号(PEXT)的外部反馈装置(旋转变压器,编码器等)进行测定。

应用图

轮的角位置是在其运行期间连续增加的主源信号。 在轮的每一圈,在一个起始和终止角度值之间进给轴应该停止。

运动曲线

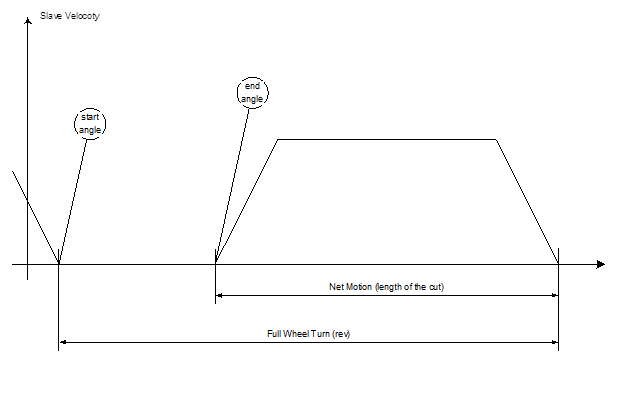

进给轴的运行曲线看起来像:

构建此应用程序的主要任务是根据以下参数设计凸轮: • 轮转角,轮转一整圈所需的pext值。 • 起始角度,冲孔开始时的轮的角度。 • 终止角度,材料移动时轮转过角度或冲孔结束时的轮的角度。 • 切割长度,在终止角度到下一个起始角度从轴位置的距离。 • 从轴的最大加速度和速度,在凸轮运动过程中不能超过这些值。 另外一个限制是决定采用速度梯形曲线来进行从动。 可以采用另一个运动曲线,但方程式将不同。 假设轮速度是恒定的,对于计算而言是已知的。 现在,要从给定的A,L,T值计算运动曲线,请参见示例末尾的附录。

程序

common shared c1 as cam

dim shared toolong as error "The given cut length is too long for the given slave accel."

dim shared toofast as error "Slave axis can not move that fast"

' Shared profile parameters:..............................................

dim shared lprof as double ' total length

dim shared aprof as double ' acceleration used

dim shared vprof as double ' cruise velocity

dim shared t_acc_prof as double ' acceleration duration

dim shared t_dec_prof as double ' end of cruise phase

dim shared t_tot_prof as double ' total velocity trapeze duration

'.........................................................................

program

' Process data

dim sangle as double = 10 ' start to cut at this angle

dim eangle as double = 60 ' finish the cut at this angle

dim rev as double = 360 ' full turn of the wheel

dim Vwheel as double = 60 ' RPM - velocity of the wheel

dim CutLength as double = 20 ' mm of the slave motion

dim CutAngle as double

dim CutTime as double

dim i as long

' Variables used in cam computation

dim t as double

dim t_from_end as double

' Creating 1000 points in the cam

createcamdata 1000 c1

' Computing the next motion

CutAngle = rev - (eangle-sangle) ' The wheel passes this angel while it moves

CutTime = CutAngle/(Vwheel*360/60) ' Time needed to move to another cut (sec)

with A1

call ProfileLTA(CutLength,CutTime,Acc)

' Start computing the cam table

' t is relative time of velocity trapeze profile

for i = 1 to c1.size

c1.MasterData[i] = (i-1)*rev/c1.size ' Defining a uniform master axis

select case (c1.MasterData[i])

case is < sangle ' it is a rotary axis in cases when master < start

' we need to compute the relative time from the end

t_from_end = (sangle - c1.MasterData[i])/(Vwheel*360/60)

t = CutTime - t_from_end

c1.SlaveData[i] = VTProfile(t) - CutLength

case is <= eangle ' master is between start and end - no motion of slave:

c1.SlaveData[i] = 0.0

case is > eangle ' Time passed after exit [start,end] master segment

t = (c1.MasterData[i]-eangle)/(Vwheel*360/60)

c1.SlaveData[i] = VTProfile(t)

end select

next

end with

with A2

' Setup the cam table

c1.Cycle = -1 ' endless camming

Attach

FirstCam = c1

MasterSource = A1.Pcmd 'For example with 2 axes

' MasterSource = pext

GearRatio = 1

Slave = CAM

SlaveDisconnect = 0

En = ON

Detach

end with

Print "Cut to length Ready"

end program

' Velocity Trapeze pre-calculation routine

' Input: Length, Total time, max Accleration

' Global used: Vmax

sub ProfileLTA(byval L as double ,byval T as double, byval A as double)

dim sqr as double

with A1

aprof = A

sqr = T^2 - 4*L/A

select case (sqr)

case is < -0.004 ' less then 4ms

throw toolong

case is < 0

' In cases of numeric computation errors (high accel. values) this could be a small

' negative number. In order to avoid math error the value is cut to zero.

sqr = 0

case else

sqr = sqrt(sqr)

end select

vprof = 0.5*A*(T - sqr)

if vprof > vmax then

throw toofast

end if

' Compute fixed points in time (end of acceleration, begin of deceleration)

t_acc_prof = vprof/A

t_dec_prof = T - t_acc_prof

t_tot_prof = T

end with

end sub

'.................................................................................

' Velocity Trapeze gernal purpose profile function

' uses shared variables:

' t_acc - time where acceleration ends (cruise starts)

' t_dec - time where deceleration starts (cruise ends)

' t_tot - end of movement

' aprof - accleration/deceleration value

' vprof - cruise (max) velocity

' lprof - total movement length

function VTProfile(byval t as double) as double

select case(t)

case is <=0

VTProfile = 0

case is <= t_acc_prof

VTProfile = 0.5*aprof*t^2

case is <= t_dec_prof

VTProfile = 0.5*vprof^2/aprof + (t-t_acc_prof)*vprof

case is < t_tot_prof

VTProfile = lprof - 0.5*aprof*(t_tot_prof-t)^2

case else

VTProfile = lprof

end select

end function

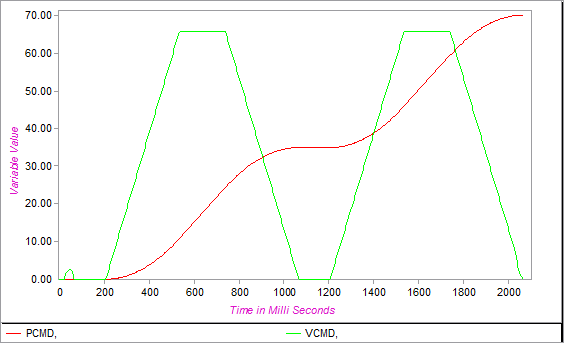

记录曲线

主轮旋转两圈(切割长度20 mm):

长度35mm,接近三角形曲线: