Difference between revisions of "Inverse Dynamic Model"

(Created page with "=Introduction - what is it good for and how does it work= =Torque Units= =How to perform the dynamic model parameters identification= =Explanation of the identification output...") |

(→Introduction - what is it good for and how does it work: new text) |

||

| Line 1: | Line 1: | ||

=Introduction - what is it good for and how does it work= | =Introduction - what is it good for and how does it work= | ||

| + | |||

| + | The inverse dynamic model (IDM) feature is used to compensate friction and dynamic effects for motion elements, otherwise leading to positioning errors and suboptimal settling and tracking behavior. | ||

| + | |||

| + | |||

| + | The motivation of the IDM feature is to use additional knowledge about the motion than just the position – i.e. velocity and torque – to offset the command values of the torque controller in order to make them react faster and thereby reduce the final positioning error and improve the settling behavior. | ||

| + | |||

| + | |||

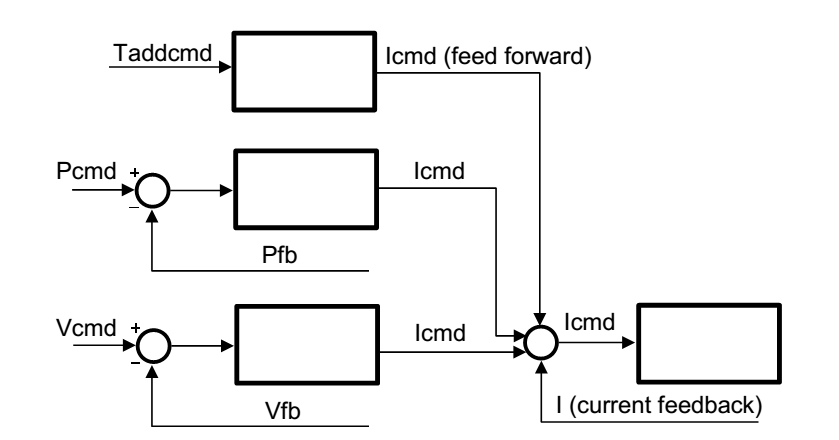

| + | The term ''inverse dynamic model'' (often named computed torque control) means that the softMC takes a cartesian motion of a motion element and not only computes the joint position for the next Cartesian setpoint, but also the joint torque required for the motion. In order to be able to do that, it needs a dynamic model – i.e., a model of the masses and inertias – of the motion element. The joint velocity and torque are then sent to the drives as additional torque command data (see Figure 1). | ||

| + | |||

| + | |||

| + | |||

| + | In most cases, the user doesn’t have the parameters of the dynamic model. In such cases, those parameters can be estimated using the softMC identification process. The softMC allows to perform measurements and estimate the dynamic model parameters of some common robot models. The identification process is performed as follows: while the robot is commanded to perform a certain movement, the movement parameters and internal motors torques are recorded. Then, the dynamic model parameters of the robot are extracted based on the robot model and the measurements. | ||

| + | |||

| + | |||

| + | [[file:DM_1.png|center|650px|frame|<center><big>''Figure 1 - A schematic drawing of the control system and the feedforward part of the Taddcmd''</big></center>]] | ||

| + | |||

=Torque Units= | =Torque Units= | ||

=How to perform the dynamic model parameters identification= | =How to perform the dynamic model parameters identification= | ||

Revision as of 09:50, 9 November 2017

Contents

- 1 Introduction - what is it good for and how does it work

- 2 Torque Units

- 3 How to perform the dynamic model parameters identification

- 4 Explanation of the identification output file

- 5 Explanation of the identification process recording file

- 6 Demonstration of tracking improvements (settling , position error)

- 7 Collision detection

- 8 Review of the possible reasons for an identification failure

- 9 How to assess what is the failure reason based on the output files

- 10 Test specifications

Introduction - what is it good for and how does it work

The inverse dynamic model (IDM) feature is used to compensate friction and dynamic effects for motion elements, otherwise leading to positioning errors and suboptimal settling and tracking behavior.

The motivation of the IDM feature is to use additional knowledge about the motion than just the position – i.e. velocity and torque – to offset the command values of the torque controller in order to make them react faster and thereby reduce the final positioning error and improve the settling behavior.

The term inverse dynamic model (often named computed torque control) means that the softMC takes a cartesian motion of a motion element and not only computes the joint position for the next Cartesian setpoint, but also the joint torque required for the motion. In order to be able to do that, it needs a dynamic model – i.e., a model of the masses and inertias – of the motion element. The joint velocity and torque are then sent to the drives as additional torque command data (see Figure 1).

In most cases, the user doesn’t have the parameters of the dynamic model. In such cases, those parameters can be estimated using the softMC identification process. The softMC allows to perform measurements and estimate the dynamic model parameters of some common robot models. The identification process is performed as follows: while the robot is commanded to perform a certain movement, the movement parameters and internal motors torques are recorded. Then, the dynamic model parameters of the robot are extracted based on the robot model and the measurements.