Difference between revisions of "Conveyor Tracking Short/zh-hans"

(Created page with "{{Languages}} =About this Document= This document presents a general overview of the softMC controller’s conveyor tracking feature. It does not provide detailed descriptio...") |

|||

| Line 2: | Line 2: | ||

| − | = | + | =关于本文档= |

| − | + | 本文档介绍了softMC控制器的传送带跟踪功能。 它不提供有关每个命令或属性的详细描述,但可以在softMC-wiki中找到。 | |

| − | + | 主要特点 | |

| − | * | + | * 与移动物体进行直接的即时同步 |

| − | * | + | * 外源的隐含接合 |

| − | * | + | * 移动坐标系(移动物体)的相对运动 |

| − | * | + | * 与移动对象的动态重新同步 |

| − | = | + | =传送带跟踪概述= |

| − | + | 传送带跟踪是softMC控制器主要用于包装应用中的的特征,其中机器人末端执行器需要与移动物体同步。 | |

| − | + | 传送带跟踪通常用于两种类型的任务。一种类型的任务是在位于移动的传送带上的容器中,将物品插入或从中提取物品。 机器人必须与传送带一起移动,使其相对于移动物体的运动为零,否则会撞击容器的侧面。另一种类型的任务在位于移动的传送带上拾取物体。 在这个任务中,机器人工具尖端(夹持器)需要与物体接触,只要需要通过机械方式或通过建立足够的吸入压力(真空)来完全抓取它。 | |

| − | + | 传送带有一个运动方向,称为流。上游位置是物体首先“出现”的位置,下游位置是物体不再在机器人范围内的位置。 | |

| − | + | 物体的移动由外部位置变量('''MasterSource''')监视。 如果在softMC控制下传动装置由驱动器驱动,变量通常是轴位置指令('''pcmd'')或反馈('''pfb''')。 如果传送带没有被softMC轴的其中一个驱动,则使用轴(辅助编码器输入)的外部位置信号('''pext''')。 | |

| − | + | 传送带是一种移动坐标系,它是用于跟踪外部坐标源(如机器人或传送带)的通用数据类型。 因此,在MC-BASIC声明语句中使用移动坐标系。 | |

| − | |||

| − | |||

| − | = | + | =典型的传送带跟踪设置= |

| − | + | 典型的传送带跟踪设置如图1所示。 | |

[[File:CNV_PIC1.PNG|700px| Figure 1. Typical conveyor tracking setup]]<br> | [[File:CNV_PIC1.PNG|700px| Figure 1. Typical conveyor tracking setup]]<br> | ||

Figure 1. Typical conveyor tracking setup | Figure 1. Typical conveyor tracking setup | ||

| − | = | + | =连接视觉系统= |

| − | + | 具有视觉系统的传送带跟踪系统如图2所示。 | |

[[File:CNV_PIC2.PNG | 700px | Figure 2. Conveyor tracking with vision system]]<br> | [[File:CNV_PIC2.PNG | 700px | Figure 2. Conveyor tracking with vision system]]<br> | ||

| Line 32: | Line 30: | ||

| − | + | 传送带跟踪系统包括触发位置,通过连接到传送带驱动器的输入探头的传感器来检测移动物体。 当检测到在传送带上移动的物体时,捕获其确切的位置。 同时,视觉系统拍摄快照并计算对象的XYR坐标。 | |

| − | + | 通过知道触发位置与工作窗口开始之间的距离(上游位置),机器人可以定位到传送带(捕获位置+距离偏移)。 一旦物体进入工作窗口,机器人将移动到该位置; 一旦与传送带同步,机器人可以对物体执行动作。 | |

| − | = | + | =将传送带定义为系统变量= |

| − | + | 传送带被定义为与机器人模型的点类型相关联的全局数据类型; 它通常在配置文件中定义(CONFIG.PRG):<br> | |

<pre> | <pre> | ||

Common shared <Conveyor Name> as moving frame of <Point Type> | Common shared <Conveyor Name> as moving frame of <Point Type> | ||

</pre> | </pre> | ||

| − | <Conveyor Name> | + | <Conveyor Name>是表示传送带的新变量(对象)的名称。 标准命名规则适用。<br> |

| − | <Point Type> | + | <Point Type> 是传送带代表的坐标系的类型。它应该与正在使用的机器人的点类型(例如,XYZ,XYZR,XYZYPR)相同。<br> |

| − | + | 例如:<br> | |

<pre> | <pre> | ||

common shared Conv as moving frame of XYZYPR | common shared Conv as moving frame of XYZYPR | ||

</pre> | </pre> | ||

| − | + | 这将Conv定义为XYZYPR(X,Y,Z,Yaw,Pitch,Roll)类型的传送带。 | |

| − | + | 传送带可以是线性或旋转,由类型属性定义: | |

<pre> | <pre> | ||

<Conveyor Name>.type = n | <Conveyor Name>.type = n | ||

</pre> | </pre> | ||

| − | + | 值:<br> | |

| − | 0 – | + | 0 – 线性<br> |

| − | 1 – | + | 1 – 旋转<br> |

| − | 2 – | + | 2 – 非耦合旋转<br> |

| − | = | + | =传送带的驱动变量= |

| − | + | 驱动传送带的变量是其主源,由MasterSource属性定义,它定义移动传送带的轴(或组)。 | |

| − | + | 该变量可以是诸如轴的位置(例如,位置指令,位置反馈或外部位置)的一维变量。 它也可以是一组独立轴的位置,或者一组完整的位置矢量。 | |

| − | + | 独立位置变量的数量定义了传送带属性ndof,其表示传送带的自由度数。 | |

| − | + | 例如:<br> | |

<pre> | <pre> | ||

Conv.Type = 1 | Conv.Type = 1 | ||

| Line 68: | Line 66: | ||

Conv.MasterSource = A1.Pext | Conv.MasterSource = A1.Pext | ||

</pre> | </pre> | ||

| − | + | 该示例表示了由轴1(a1)的外部位置命令驱动的一维线性传送带的声明。 | |

| − | + | 如果传送带由外部电机(即不受softMC控制的电机)启动,则通过将外部编码器物理连接到连接到驱动器('''pext''')的外部位置输入(辅助编码器)的传送带来测量其运动。 | |

| − | = | + | =将传送带连接到机器人= |

| − | + | 在开始传送带跟踪之前,传送带必须通过声明来连接到机器人,例如:<br> | |

<pre> | <pre> | ||

Puma.MasterFrame = conv | Puma.MasterFrame = conv | ||

</pre> | </pre> | ||

| − | + | 该命令建立了传送带和机器人之间的关系(链接),并保持传送带和机器人位置的独立性。 此命令不会激活传送带跟踪。 仅当属性从属设置为5时,实际的传送带跟踪才会开始。 | |

| − | = | + | =传送带的工作窗口= |

| − | + | 机器人可以与传送带同步的区域或范围称为工作窗口。 对于线性传送带,它由上游和下游位置定义。 对于旋转传送带,圆形路径由位于上游和下游位置之间的附加点(ArcPoint)定义。 通过将它们的值分配给任何其他位置数据类型(作为表达式或常量)来定义这些点。例如:<br> | |

| − | |||

| − | |||

<pre> | <pre> | ||

Conv.UpStream[1] = #{100,0,0,0,0,0} | Conv.UpStream[1] = #{100,0,0,0,0,0} | ||

Conv.DownStream[1] = #{250,0,0,0,0,0} | Conv.DownStream[1] = #{250,0,0,0,0,0} | ||

</pre> | </pre> | ||

| − | + | 在这个例子中,线性传送带的工作窗口沿着与X坐标平行的线定义,从X = 100开始,以X = 250结束。<br> | |

| − | + | 注意,该示例中的索引[1]表示传送带已经被定义为一个自由度(nd = 1)<br> | |

| − | + | 要定义传送带运动,需要为工作窗口(上游,下游和旋转传送带的ArcPoint)中的每个点分配主坐标。 两个传送带属性UpMaster[1]和DownMaster[1]设置主轴的值,并对应于UpStream和DownStream点。 因此,当主轴处于UpMaster[1]位置时,传送带上的物体处于UpStream点。 这些点被触发位置所抵消,这将在本文后面讨论。) | |

| − | + | 例如:<br> | |

<pre> | <pre> | ||

Conv.UpMaster[1] = 1000 | Conv.UpMaster[1] = 1000 | ||

Conv.DownMaster[1] = 2000 | Conv.DownMaster[1] = 2000 | ||

</pre> | </pre> | ||

| − | + | 在该示例中(假设偏移为0),当主轴(a1.pext)为'''1000''' (a1.pext = 1000)时,传送带对象位于#{100,0,0,0,0,0}。 当主轴(a1.pext)为'''2000''' (a1.pext = 1000)时,传送带物体位于#{250,0,0,0,0,0}处。这也意味着传送带每'''1 mm''' 的主轴单位为'''1000/150 = 6.66'''。 | |

[[File:CNV_PIC3.PNG | Figure 3. Catching the item on a rotary conveyor “MOVES CNV.ZERO”]]<br> | [[File:CNV_PIC3.PNG | Figure 3. Catching the item on a rotary conveyor “MOVES CNV.ZERO”]]<br> | ||

Figure 3. Catching the item on a rotary conveyor “MOVES CNV.ZERO” | Figure 3. Catching the item on a rotary conveyor “MOVES CNV.ZERO” | ||

| − | = | + | =传送带位置循环= |

| − | + | 传送带内在的循环。传送带的主位置是不断增加的值,为了获得传送带的周期性,必须引入主轴位置的触发偏移。偏移值由触发命令发出。 | |

| − | + | 例如:<br> | |

<pre> | <pre> | ||

Trigger puma Ndof = 1 Value = 300 | Trigger puma Ndof = 1 Value = 300 | ||

</pre> | </pre> | ||

| − | + | 在此示例中,触发命令将主轴的主位置偏移300个位置单元。这意味着下一个工作窗口将在主站位置的1300到2300之间。触发器可以缓冲; 最多可以在系统中存储16个触发值。到目前为止输入的触发值的数量可以使用属性<conveyor> .noi进行查询。 每次启动传送带跟踪(slave=5)时,将一个值从触发缓冲区中取出。 每次传送带脱开时,跟踪被分离(slave=0),另一个值从缓冲器中取出。触发是启动跟踪的条件。 触发命令指定用作参考点的主位置。跟踪过程中的所有主位置相对于此点进行重新计算。如果在实际触发和位置更新之间存在延迟,则可以通过向触发命令指定的位置添加偏移来补偿差异。偏移量由用户决定。 触发命令中指定的值作为确定工作窗口的参考,如下例所示。 | |

| − | |||

| − | |||

| − | |||

| − | |||

[[File:CNV_PIC4.PNG |Figure 4. Master position values]]<br> | [[File:CNV_PIC4.PNG |Figure 4. Master position values]]<br> | ||

| Line 115: | Line 107: | ||

| − | + | A(UpMaster [1])和B(DownMaster [1])是上下限位置。 <br> | |

| − | + | X是触发命令中指定的值。<br> | |

| − | + | M是当前的主位置。 因此,目前窗口的实际限制: <br> | |

| − | + | 下限: L = X + A <br> | |

| − | + | 上限: U = X + B <br> | |

| − | IsInWindow = (L <= M) | + | IsInWindow = (L <= M) 和 (M <= U) <br> |

| − | = | + | =变量监控= |

| − | + | 以下变量用于监测传送带跟踪过程: | |

| − | <conveyor>.IIW (Is In Window) | + | <conveyor>.IIW (Is In Window)(0或1)表示机器人是否在工作窗口内。 |

| − | <robot>.IMFS (Is Motion Frame Synchronized) ( | + | <robot>.IMFS (Is Motion Frame Synchronized) (0或1)表示机器人是否与传送带完全同步。 |

| − | <conveyor>. | + | <conveyor>.here传送带上的运动物体的实际位置。 |

| − | <conveyor>. | + | <conveyor>.zero是触发后对象出现的工作窗口内的位置。 |

[[File:CNV_PIC5.PNG| Figure 5. Working window and monitoring variables]]<br> | [[File:CNV_PIC5.PNG| Figure 5. Working window and monitoring variables]]<br> | ||

Figure 5. Working window and monitoring variables | Figure 5. Working window and monitoring variables | ||

| − | = | + | =开始传送带跟踪= |

| − | + | 通过更改机器人的从属性来启动传送带跟踪。 | |

| − | + | 例如: | |

Puma.slave = 5 | Puma.slave = 5 | ||

| − | + | 此命令启动同步过程。 如果没有其他命令生效,则机器人末端执行器将与从属性更改的位置平行移动。 | |

| − | + | 在传送带跟踪中有三个不同的阶段: | |

Synchronization | Synchronization | ||

Tracking | Tracking | ||

| Line 145: | Line 137: | ||

Figure 6. Synchronization – De-synchronization sequence during conveyor tracking | Figure 6. Synchronization – De-synchronization sequence during conveyor tracking | ||

| − | + | 第一个阶段是同步。在这个阶段中,机器人试着跟上传送带的位置运动。如果传送带速度太快,机器人不能跟上。 | |

| − | + | 机器人同步的运动学参数为: <br> | |

puma.velocitySyncTran <br> | puma.velocitySyncTran <br> | ||

puma.accelerationSyncTran <br> | puma.accelerationSyncTran <br> | ||

| Line 155: | Line 147: | ||

puma.jerkSyncRot <br> | puma.jerkSyncRot <br> | ||

| − | + | 这些参数都需要设置为比机器人(vtran,...)的标准参数略高的值。 一旦从机从0变为5,同步开始。 在同步期间,<robot> .imfs = 0。一旦机器人与传送带同步,将<robot> .imfs标志设置为1.一旦从属状态改变,传送带上的物体就会开始移动。 这可以通过属性<Conveyor>.here来追踪,这返回传送带运动的位置。 如果物体退出工作窗口,则报告错误,并且传送带跟踪被分离。 一旦完成了移动传送带上的动作,机器人就脱离传送带。 此阶段称为去同步,在此期间<robot> .imfs = 1。去同步参数为: <br> | |

| − | |||

| − | |||

| − | |||

puma.velocityDeSyncTran <br> | puma.velocityDeSyncTran <br> | ||

puma.accelerationDeSyncTran <br> | puma.accelerationDeSyncTran <br> | ||

| Line 166: | Line 155: | ||

puma.accelerationDeSyncRot <br> | puma.accelerationDeSyncRot <br> | ||

puma.jerkDeSyncRot <br> | puma.jerkDeSyncRot <br> | ||

| − | + | 至关重要的是机器人至少要比传送带快两倍。传送带的最大速度和其他限制由以下设定: | |

Conv.VelocityMaxRot= … <br> | Conv.VelocityMaxRot= … <br> | ||

Conv.AccelerationMaxRot = … <br> | Conv.AccelerationMaxRot = … <br> | ||

Conv.JerkmaxRot= … <br> | Conv.JerkmaxRot= … <br> | ||

| − | + | 这些仅是监视值。 如果超过任何一个,报告错误。 | |

| − | = | + | =传送带上物体原点的位置= |

| − | + | 移动对象在工作窗口中出现的位置是通过属性<Conveyor> .zero获取的,该位置是位置数据类型。它表示同步开始时对象的位置; 如果在主位置变得大于<conveyor> .UpMaster [1]之前同步开始,则返回<transport> .UpStream [1]值。 | |

| − | = | + | =传送带跟踪期间的绝对运动 = |

| − | + | "机器人总位置"是将机器人的笛卡尔位置转换成关节位置,实际上是发送到运动总线(EtherCAT)上的驱动器的坐标。 | |

| − | + | 传送带跟踪期间的总位置由机器人运动和传送带运动两部分组成。 机器人运动是运动命令(如MOVE和MOVES)引入的坐标变化。 传送带运动是传送带在不同阶段(同步,跟踪,去同步)的运动。 总机器人位置表示为: | |

| − | |||

Total = Robot + Conveyor | Total = Robot + Conveyor | ||

| − | + | 传送带坐标为: <br> | |

Conveyor(t) = CNV(t) - CNV(t0)<br> | Conveyor(t) = CNV(t) - CNV(t0)<br> | ||

| − | + | t0是发出 "slave=5" 的时刻<br> | |

| − | + | 对线性传送带,CNV是: <br> | |

CNV(t) = (DownStream - UpStream)*(Master(t) - Trigger)/ (DownMaster - UpMaster[1]) <br> | CNV(t) = (DownStream - UpStream)*(Master(t) - Trigger)/ (DownMaster - UpMaster[1]) <br> | ||

| − | Master(t) | + | Master(t)是t时刻的传送带主轴的位置。 <br> |

| − | DownStream, Upstream, DownMaster, and | + | DownStream, Upstream, DownMaster, and UpMaster是传送带参数。<br> |

| − | + | 与MC-BASIC变量的关系: <br> | |

Conv.here = CNV(t) <br> | Conv.here = CNV(t) <br> | ||

Conv.zero = CNV(0) <br> | Conv.zero = CNV(0) <br> | ||

| − | + | 在这背后是,当传送带移动时和传送带静止时,查询/命令的机器人位置是相同的。因此,为了示教传送带上的点,只需停止传送带,并将机器人移动到皮带旁边的目标位置。机器人运动,即主方程中的机器人变量,是机器人在传送带跟踪过程中的绝对位置; 它等于作为运动命令的目标点输入的位置(例如,MOVES / CIRCLE)。 | |

| − | |||

| − | |||

| − | == | + | == 详细说明 == |

| − | + | 参考: [[Conveyor_Tracking_General|Conveyor_Tracking]] | |

[[Category:Motion:MovingFrame]] | [[Category:Motion:MovingFrame]] | ||

[[Category:Motion Control|Conveyor Tracking]] | [[Category:Motion Control|Conveyor Tracking]] | ||

Revision as of 17:45, 29 May 2017

| 语言: | [[::Conveyor Tracking Short|English]] • [[::Conveyor Tracking Short/zh-hans|中文(简体)]] |

|---|

Contents

关于本文档

本文档介绍了softMC控制器的传送带跟踪功能。 它不提供有关每个命令或属性的详细描述,但可以在softMC-wiki中找到。 主要特点

- 与移动物体进行直接的即时同步

- 外源的隐含接合

- 移动坐标系(移动物体)的相对运动

- 与移动对象的动态重新同步

传送带跟踪概述

传送带跟踪是softMC控制器主要用于包装应用中的的特征,其中机器人末端执行器需要与移动物体同步。 传送带跟踪通常用于两种类型的任务。一种类型的任务是在位于移动的传送带上的容器中,将物品插入或从中提取物品。 机器人必须与传送带一起移动,使其相对于移动物体的运动为零,否则会撞击容器的侧面。另一种类型的任务在位于移动的传送带上拾取物体。 在这个任务中,机器人工具尖端(夹持器)需要与物体接触,只要需要通过机械方式或通过建立足够的吸入压力(真空)来完全抓取它。 传送带有一个运动方向,称为流。上游位置是物体首先“出现”的位置,下游位置是物体不再在机器人范围内的位置。 物体的移动由外部位置变量('MasterSource)监视。 如果在softMC控制下传动装置由驱动器驱动,变量通常是轴位置指令(pcmd)或反馈(pfb)。 如果传送带没有被softMC轴的其中一个驱动,则使用轴(辅助编码器输入)的外部位置信号(pext)。 传送带是一种移动坐标系,它是用于跟踪外部坐标源(如机器人或传送带)的通用数据类型。 因此,在MC-BASIC声明语句中使用移动坐标系。

典型的传送带跟踪设置

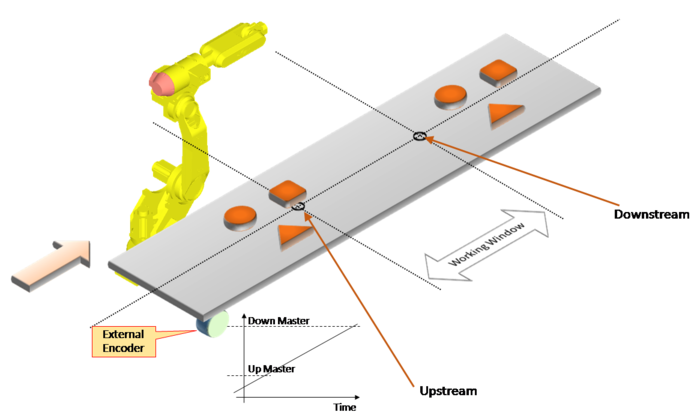

典型的传送带跟踪设置如图1所示。

Figure 1. Typical conveyor tracking setup

连接视觉系统

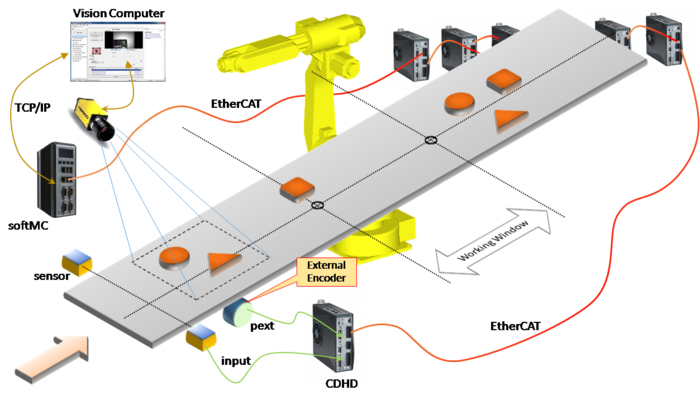

具有视觉系统的传送带跟踪系统如图2所示。

Figure 2. Conveyor tracking with vision system

传送带跟踪系统包括触发位置,通过连接到传送带驱动器的输入探头的传感器来检测移动物体。 当检测到在传送带上移动的物体时,捕获其确切的位置。 同时,视觉系统拍摄快照并计算对象的XYR坐标。

通过知道触发位置与工作窗口开始之间的距离(上游位置),机器人可以定位到传送带(捕获位置+距离偏移)。 一旦物体进入工作窗口,机器人将移动到该位置; 一旦与传送带同步,机器人可以对物体执行动作。

将传送带定义为系统变量

传送带被定义为与机器人模型的点类型相关联的全局数据类型; 它通常在配置文件中定义(CONFIG.PRG):

Common shared <Conveyor Name> as moving frame of <Point Type>

<Conveyor Name>是表示传送带的新变量(对象)的名称。 标准命名规则适用。

<Point Type> 是传送带代表的坐标系的类型。它应该与正在使用的机器人的点类型(例如,XYZ,XYZR,XYZYPR)相同。

例如:

common shared Conv as moving frame of XYZYPR

这将Conv定义为XYZYPR(X,Y,Z,Yaw,Pitch,Roll)类型的传送带。

传送带可以是线性或旋转,由类型属性定义:

<Conveyor Name>.type = n

值:

0 – 线性

1 – 旋转

2 – 非耦合旋转

传送带的驱动变量

驱动传送带的变量是其主源,由MasterSource属性定义,它定义移动传送带的轴(或组)。

该变量可以是诸如轴的位置(例如,位置指令,位置反馈或外部位置)的一维变量。 它也可以是一组独立轴的位置,或者一组完整的位置矢量。

独立位置变量的数量定义了传送带属性ndof,其表示传送带的自由度数。

例如:

Conv.Type = 1 Conv.Ndof = 1 Conv.MasterSource = A1.Pext

该示例表示了由轴1(a1)的外部位置命令驱动的一维线性传送带的声明。 如果传送带由外部电机(即不受softMC控制的电机)启动,则通过将外部编码器物理连接到连接到驱动器(pext)的外部位置输入(辅助编码器)的传送带来测量其运动。

将传送带连接到机器人

在开始传送带跟踪之前,传送带必须通过声明来连接到机器人,例如:

Puma.MasterFrame = conv

该命令建立了传送带和机器人之间的关系(链接),并保持传送带和机器人位置的独立性。 此命令不会激活传送带跟踪。 仅当属性从属设置为5时,实际的传送带跟踪才会开始。

传送带的工作窗口

机器人可以与传送带同步的区域或范围称为工作窗口。 对于线性传送带,它由上游和下游位置定义。 对于旋转传送带,圆形路径由位于上游和下游位置之间的附加点(ArcPoint)定义。 通过将它们的值分配给任何其他位置数据类型(作为表达式或常量)来定义这些点。例如:

Conv.UpStream[1] = #{100,0,0,0,0,0}

Conv.DownStream[1] = #{250,0,0,0,0,0}

在这个例子中,线性传送带的工作窗口沿着与X坐标平行的线定义,从X = 100开始,以X = 250结束。

注意,该示例中的索引[1]表示传送带已经被定义为一个自由度(nd = 1)

要定义传送带运动,需要为工作窗口(上游,下游和旋转传送带的ArcPoint)中的每个点分配主坐标。 两个传送带属性UpMaster[1]和DownMaster[1]设置主轴的值,并对应于UpStream和DownStream点。 因此,当主轴处于UpMaster[1]位置时,传送带上的物体处于UpStream点。 这些点被触发位置所抵消,这将在本文后面讨论。)

例如:

Conv.UpMaster[1] = 1000 Conv.DownMaster[1] = 2000

在该示例中(假设偏移为0),当主轴(a1.pext)为1000 (a1.pext = 1000)时,传送带对象位于#{100,0,0,0,0,0}。 当主轴(a1.pext)为2000 (a1.pext = 1000)时,传送带物体位于#{250,0,0,0,0,0}处。这也意味着传送带每1 mm 的主轴单位为1000/150 = 6.66。

Figure 3. Catching the item on a rotary conveyor “MOVES CNV.ZERO”

传送带位置循环

传送带内在的循环。传送带的主位置是不断增加的值,为了获得传送带的周期性,必须引入主轴位置的触发偏移。偏移值由触发命令发出。

例如:

Trigger puma Ndof = 1 Value = 300

在此示例中,触发命令将主轴的主位置偏移300个位置单元。这意味着下一个工作窗口将在主站位置的1300到2300之间。触发器可以缓冲; 最多可以在系统中存储16个触发值。到目前为止输入的触发值的数量可以使用属性<conveyor> .noi进行查询。 每次启动传送带跟踪(slave=5)时,将一个值从触发缓冲区中取出。 每次传送带脱开时,跟踪被分离(slave=0),另一个值从缓冲器中取出。触发是启动跟踪的条件。 触发命令指定用作参考点的主位置。跟踪过程中的所有主位置相对于此点进行重新计算。如果在实际触发和位置更新之间存在延迟,则可以通过向触发命令指定的位置添加偏移来补偿差异。偏移量由用户决定。 触发命令中指定的值作为确定工作窗口的参考,如下例所示。

Figure 4. Master position values

A(UpMaster [1])和B(DownMaster [1])是上下限位置。

X是触发命令中指定的值。

M是当前的主位置。 因此,目前窗口的实际限制:

下限: L = X + A

上限: U = X + B

IsInWindow = (L <= M) 和 (M <= U)

变量监控

以下变量用于监测传送带跟踪过程: <conveyor>.IIW (Is In Window)(0或1)表示机器人是否在工作窗口内。 <robot>.IMFS (Is Motion Frame Synchronized) (0或1)表示机器人是否与传送带完全同步。 <conveyor>.here传送带上的运动物体的实际位置。 <conveyor>.zero是触发后对象出现的工作窗口内的位置。

Figure 5. Working window and monitoring variables

开始传送带跟踪

通过更改机器人的从属性来启动传送带跟踪。 例如: Puma.slave = 5 此命令启动同步过程。 如果没有其他命令生效,则机器人末端执行器将与从属性更改的位置平行移动。 在传送带跟踪中有三个不同的阶段: Synchronization Tracking De-synchronization

Figure 6. Synchronization – De-synchronization sequence during conveyor tracking

第一个阶段是同步。在这个阶段中,机器人试着跟上传送带的位置运动。如果传送带速度太快,机器人不能跟上。

机器人同步的运动学参数为:

puma.velocitySyncTran

puma.accelerationSyncTran

puma.jerkSyncTran

puma.velocitySyncRot

puma.accelerationSyncRot

puma.jerkSyncRot

这些参数都需要设置为比机器人(vtran,...)的标准参数略高的值。 一旦从机从0变为5,同步开始。 在同步期间,<robot> .imfs = 0。一旦机器人与传送带同步,将<robot> .imfs标志设置为1.一旦从属状态改变,传送带上的物体就会开始移动。 这可以通过属性<Conveyor>.here来追踪,这返回传送带运动的位置。 如果物体退出工作窗口,则报告错误,并且传送带跟踪被分离。 一旦完成了移动传送带上的动作,机器人就脱离传送带。 此阶段称为去同步,在此期间<robot> .imfs = 1。去同步参数为:

puma.velocityDeSyncTran

puma.accelerationDeSyncTran

puma.jerkDeSyncTran

puma.velocityDeSyncRot

puma.accelerationDeSyncRot

puma.jerkDeSyncRot

至关重要的是机器人至少要比传送带快两倍。传送带的最大速度和其他限制由以下设定:

Conv.VelocityMaxRot= …

Conv.AccelerationMaxRot = …

Conv.JerkmaxRot= …

这些仅是监视值。 如果超过任何一个,报告错误。

传送带上物体原点的位置

移动对象在工作窗口中出现的位置是通过属性<Conveyor> .zero获取的,该位置是位置数据类型。它表示同步开始时对象的位置; 如果在主位置变得大于<conveyor> .UpMaster [1]之前同步开始,则返回<transport> .UpStream [1]值。

传送带跟踪期间的绝对运动

"机器人总位置"是将机器人的笛卡尔位置转换成关节位置,实际上是发送到运动总线(EtherCAT)上的驱动器的坐标。

传送带跟踪期间的总位置由机器人运动和传送带运动两部分组成。 机器人运动是运动命令(如MOVE和MOVES)引入的坐标变化。 传送带运动是传送带在不同阶段(同步,跟踪,去同步)的运动。 总机器人位置表示为:

Total = Robot + Conveyor

传送带坐标为:

Conveyor(t) = CNV(t) - CNV(t0)

t0是发出 "slave=5" 的时刻

对线性传送带,CNV是:

CNV(t) = (DownStream - UpStream)*(Master(t) - Trigger)/ (DownMaster - UpMaster[1])

Master(t)是t时刻的传送带主轴的位置。

DownStream, Upstream, DownMaster, and UpMaster是传送带参数。

与MC-BASIC变量的关系:

Conv.here = CNV(t)

Conv.zero = CNV(0)

在这背后是,当传送带移动时和传送带静止时,查询/命令的机器人位置是相同的。因此,为了示教传送带上的点,只需停止传送带,并将机器人移动到皮带旁边的目标位置。机器人运动,即主方程中的机器人变量,是机器人在传送带跟踪过程中的绝对位置; 它等于作为运动命令的目标点输入的位置(例如,MOVES / CIRCLE)。