Difference between revisions of "Flying Shear Application"

(→Motion profile) |

|||

| Line 1: | Line 1: | ||

= Introduction = | = Introduction = | ||

The task of a flying shear application is to cut a constantly moving material to a predefined length. Unlike the punch-cutting, the cutting is done in motion. In flying shear application, the motion task must remain synchronized the master and slave axis for a certain period of time and then go back to the initial position as fast as possible to be ready for the next cut. An optional sensor for length correction can be added. Although this is presented as a cutting application, the example can be used for other applications, such as applying labels or printing markings on the product. The application sets an output when the synchronization point is reached. This output can start the cutting mechanism but could start any other printing or labeling device. | The task of a flying shear application is to cut a constantly moving material to a predefined length. Unlike the punch-cutting, the cutting is done in motion. In flying shear application, the motion task must remain synchronized the master and slave axis for a certain period of time and then go back to the initial position as fast as possible to be ready for the next cut. An optional sensor for length correction can be added. Although this is presented as a cutting application, the example can be used for other applications, such as applying labels or printing markings on the product. The application sets an output when the synchronization point is reached. This output can start the cutting mechanism but could start any other printing or labeling device. | ||

| − | = | + | =Application Diagram = |

[[File:flyshr1.png]] | [[File:flyshr1.png]] | ||

| Line 194: | Line 194: | ||

</syntaxhighlight> | </syntaxhighlight> | ||

| + | |||

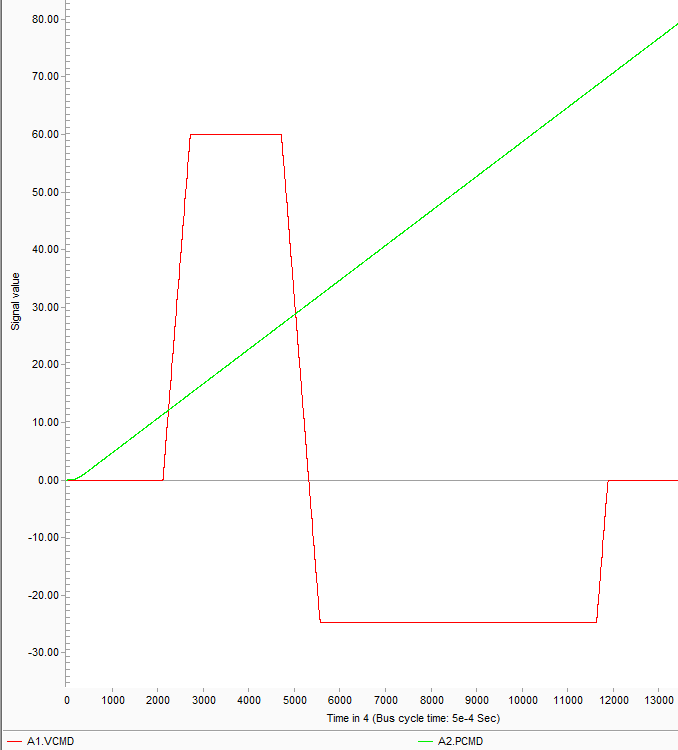

| + | = Output = | ||

| + | |||

| + | [[File:flyshr4.png]] | ||

Revision as of 12:20, 26 April 2017

Introduction

The task of a flying shear application is to cut a constantly moving material to a predefined length. Unlike the punch-cutting, the cutting is done in motion. In flying shear application, the motion task must remain synchronized the master and slave axis for a certain period of time and then go back to the initial position as fast as possible to be ready for the next cut. An optional sensor for length correction can be added. Although this is presented as a cutting application, the example can be used for other applications, such as applying labels or printing markings on the product. The application sets an output when the synchronization point is reached. This output can start the cutting mechanism but could start any other printing or labeling device.

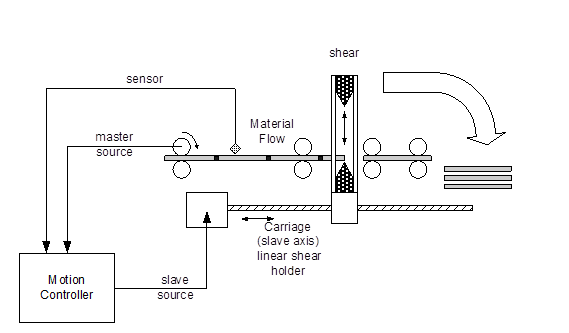

Application Diagram

The approximate motion profile for a flying shear application looks like:

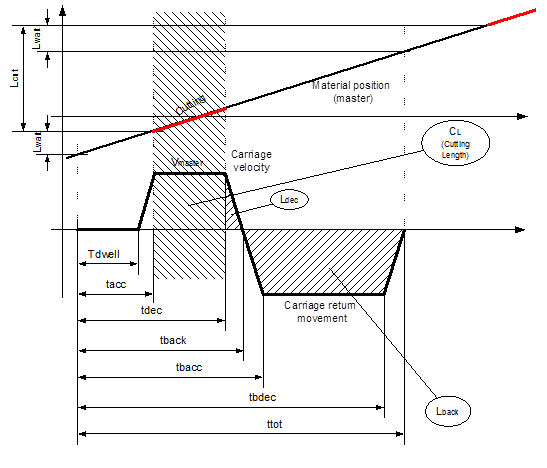

Motion profile

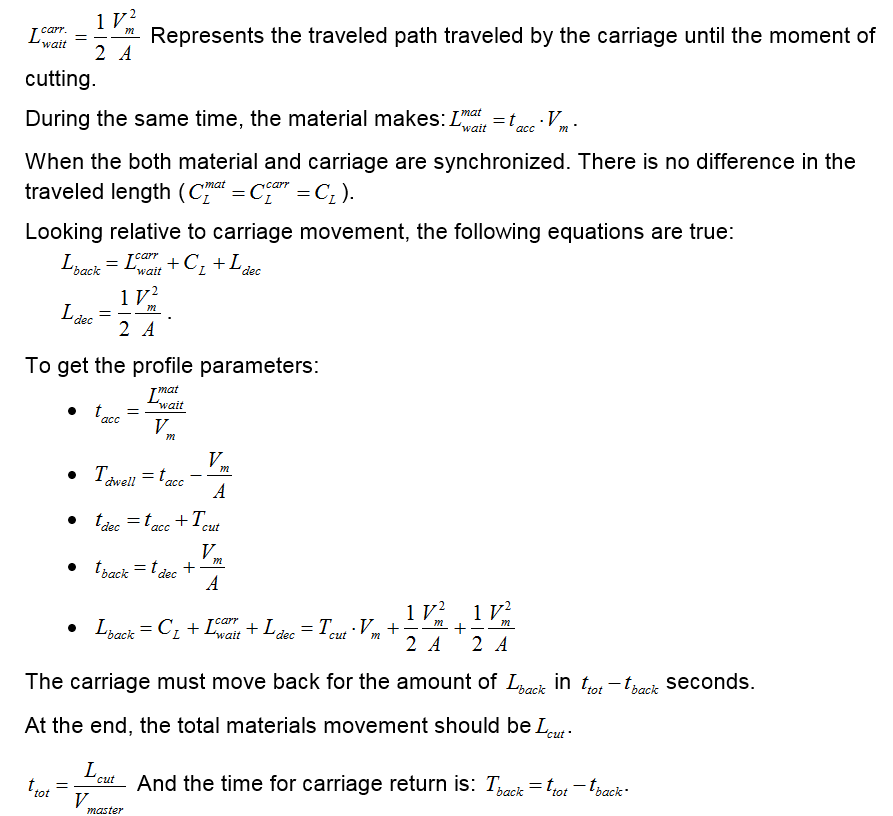

The motion is divided into three phases. The first phase includes the carriage dwell time. The carriage acceleration to the synchronization point is the phase where the carriage should be synchronized to a cut length of the master axis. The second phase or cutting is determined by the time needed for the cutting process to be completed. This phase is determined by cut time or the passed path of the material. The third and last phase is the return of the carriage to its home position. We assume that material flow velocity is constant and known: Vm. Further, we assume that both acceleration and deceleration values are the same. To get the cam profile parameters, use the following equations:

Here, known are L, T and A. The requested are profiler parameters tacc, tdec,v. Using the above equations, the code for the flying shear application is below (using the VTProfile and ProfileLTA routines from the Cut To Length example):

Program

common shared c1 as cam

dim shared toolong as error "The given cut length is too long for the given slave accel."

dim shared toofast as error "Slave axis can not move that fast"

dim shared tooshortw as error "Waiting period too short"

' Shared profile parameters:..............................................

dim shared lprof as double ' total legth

dim shared aprof as double ' acceleration used

dim shared vprof as double ' cruise velocity

dim shared t_acc_prof as double ' acceleration duration

dim shared t_dec_prof as double ' end of cruise phase

dim shared t_tot_prof as double ' total velocity trapeze duration

'.........................................................................

program

dim i as long

' Process data

dim Vmaster as double

dim CutLength as double

dim CutTime as double

dim DwellTime as double

dim BackLength as double

dim WaitLengthMaster as double

dim WaitLengthSlave as double

dim DecLength as double

dim CutPath as double

' Cam profile parameters

dim t_acc as double

dim t_dec as double

dim t_back as double

dim t_tot as double

dim vback as double

' Variables used in cam computation

dim t as double

dim dt as double

WaitLengthMaster = 15 ' Length in mm that is passed before the carriage is synchronized

Vmaster = 60 ' mm/sec - velocity of the material

CutLength = 70 ' mm of the master material feed

CutTime = 0.2 ' Time 200 ms needed for the cut

with A1 'A1 = Carriage (Slave)

Attach

Slave=0

FirstCam = none

CreateCamData 1000 c1 ' Creating 1000 points in the cam

CutPath = Vmaster*CutTime ' Path traveled during cutting process

t_acc = WaitLengthMaster/Vmaster ' end of acceleration

DwellTime = t_acc - Vmaster/acc ' dwell duration

if DwellTime < 0 then

throw tooshortw

end if

t_dec = t_acc + CutTime ' Time to start deceleration.

t_back = t_dec + Vmaster/acc ' Time to starts carriage return

t_tot = CutLength/Vmaster ' Total time of the movement is

WaitLengthSlave = 0.5*Vmaster^2/acc ' Path passed by slave during waiting

DecLength = 0.5*Vmaster^2/acc ' Path passed by slave during deceleration

BackLength = CutPath + WaitLengthSlave + DecLength ' Total movement length

' Setting for the first trapeze (forward carriage motion)

lprof = CutPath + WaitLengthSlave + DecLength

aprof = acc

vprof = Vmaster

t_acc_prof = t_acc - DwellTime

t_dec_prof = t_dec - DwellTime

t_tot_prof = t_back - DwellTime

dt = t_tot/(c1.size-1)

t = 0

while t <= t_back

i = round(t/dt) +1

c1.MasterData[i] = t*Vmaster

if t < DwellTime then

c1.SlaveData[i] = 0

else

c1.SlaveData[i] = VTProfile(t-DwellTime)

end if

t = t + dt

end while

' Next trapeze (carriage return)

lprof = CutPath + WaitLengthSlave + DecLength

call ProfileLTA(lprof ,t_tot - t_back, acc)

while t <= t_tot

i = round(t/dt) +1

c1.MasterData[i] = t*Vmaster

c1.SlaveData[i] = BackLength - VTProfile(t-t_back)

t = t + dt

end while

c1.MasterData[c1.size] = CutLength

c1.SlaveData[c1.size] = 0

' Setup the camming

c1.Cycle = -1 ' endless camming

FirstCam = c1

MasterSource = A2.Pcmd

GearRatio = 1

Slave = cam

En = ON

Detach A1

end with

Print "Flying Shear Ready"

end program

'.................................................................................

' Velocity Trapeze gernal purpose profile function

' uses shared variables:

' t_acc - time where acceleration ends (cruise starts)

' t_dec - time where deceleration starts (cruise ends)

' t_tot - end of movement

' aprof - accleration/deceleration value

' vprof - cruise (max) velocity

' lprof - total movement length

function VTProfile(byval t as double) as double

select case(t)

case is <=0

VTProfile = 0

case is <= t_acc_prof

VTProfile = 0.5*aprof*t^2

case is <= t_dec_prof

VTProfile = 0.5*vprof^2/aprof + (t-t_acc_prof)*vprof

case is < t_tot_prof

VTProfile = lprof - 0.5*aprof*(t_tot_prof-t)^2

case else

VTProfile = lprof

end select

end function

' Velocity Trapeze pre-calculation routine

' Input: Length, Total time, max Accleration

' Global used: Vmax

sub ProfileLTA(byval L as double ,byval T as double, byval A as double)

dim sqr as double

with A1

aprof = A

sqr = T^2 - 4*L/A

select case (sqr)

case is < -0.004 ' less then 4ms

throw toolong

case is < 0

' In cases of numeric computation errors (high accel. values) this could be a small

' negative number. In order to avoid math error the value is cut to zero.

sqr = 0

case else

sqr = sqrt(sqr)

end select

vprof = 0.5*A*(T - sqr)

if vprof > vmax then

throw toofast

end if

' Compute fixed points in time (end of acceleration, begin of deceleration)

t_acc_prof = vprof/A

t_dec_prof = T - t_acc_prof

t_tot_prof = T

end with

end sub