Difference between revisions of "How to setup Position Error Delay"

(added referance for simulated axes pedel) |

(→How to SetUp Position Error Delay) |

||

| Line 1: | Line 1: | ||

= How to SetUp Position Error Delay = | = How to SetUp Position Error Delay = | ||

| + | |||

| + | |||

| + | {{Note/Warning| If working with CDHD Servotronix family of drives over EtherCAT pay attention that in order to get position proper error values it is extremely important to '''switch off''' the CDHD's smoothing feature by setting MOVESMOOTHMODE to 0. The CDHD's position smoothing is obsolete in applications with SoftMC as the SoftMC already smoothenizes its output (PCMD values).}} | ||

| + | |||

== First Step == | == First Step == | ||

Revision as of 09:41, 1 June 2015

How to SetUp Position Error Delay

| WARNING | |

| If working with CDHD Servotronix family of drives over EtherCAT pay attention that in order to get position proper error values it is extremely important to switch off the CDHD's smoothing feature by setting MOVESMOOTHMODE to 0. The CDHD's position smoothing is obsolete in applications with SoftMC as the SoftMC already smoothenizes its output (PCMD values). |

First Step

- set PEDEL to 1 (minimum value)

- set high value in PeMax

- Run the axis back and forth and record PE and VCMD as :

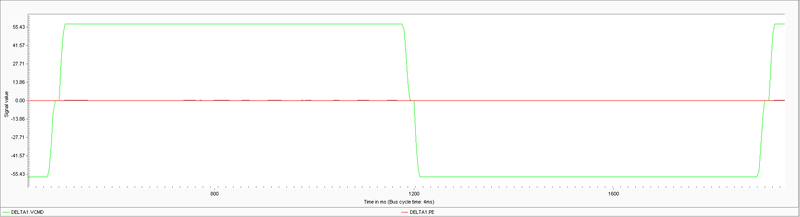

Command Velocity recordings

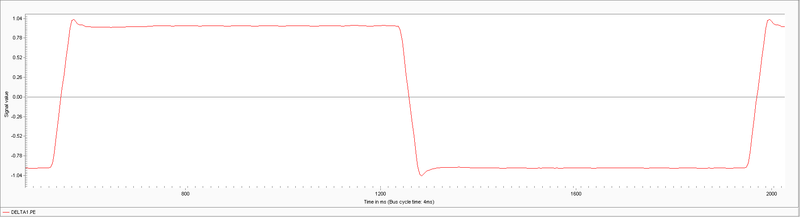

Position Error recordings

Compute PEDEL as PE/VCMD, in this case it will be:

PE/VCMD = 0.94/57.74*1000 = 16.2 ms

Taking into account the used value of PEDEL (1) and the sampling time of 4ms we get the new PEDEL value of 5, e.i. PEDEL = 1 + 4 = 5

| NOTE | |

in case of a simulated axis the same procedure will work, typically results will show round cycle of 1.

eg, PE/VCMD = 0.4 / 100.0 * 1000.0 = 4 ms = 1 bus cycle |

Second Step

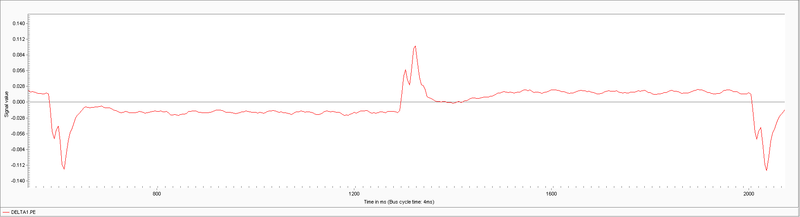

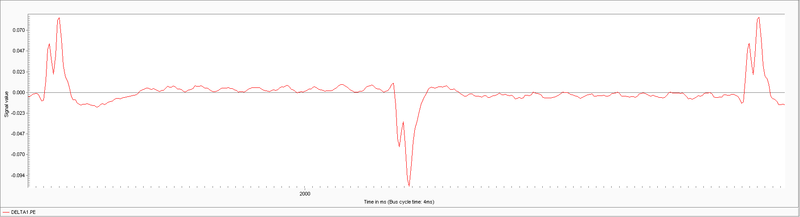

Change the PEDEL(5) to the integer value estimated before and run the test again:

again estimate the error:

PE/VCMD = 0.18/57.74*1000 = 0.317 ms

| IMPORTANT | |

| This means the non-integer communication delay of the drive is 317 micro-seconds. |

which is in units of one sample equal:

317/4000 = 0.078

So setting PEDEL to 5.078 we get:

Example File

PDLtune.prg

'

common shared Ax as generic Axis

program

dim i as long

Ax = A1

with Ax

Attach

Pedel = 1 ' first run

Pedel = 1 + round(1.68 / 100.0 * 1000.0 / (bus[0].cycleTime/1000)) ' 2nd run. extracted from recordings

Pedel = Pedel + 0.075 / 100.0 * 1000.0 / (bus[0].cycleTime/1000) ' 3rd run. extracted from recordings

PeMax = 10

En=1

Sleep 100

Move 0 Vcruise=100 Abs=TRUE

call waitMotion

Record ax_PE.rec 100000 Gap=1 RecData = Ax.Pe, Ax.Vcmd

RecordOn

Sleep 100

for i = 1 to 3

Move 100 Vcruise=100 Abs=TRUE

call waitMotion

Sleep 100

Move 0 Vcruise=100 Abs=TRUE

call waitMotion

Sleep 100

next

RecordClose

En=FALSE

Sleep 100

PeMax = 0.1

Detach

end with

terminate program

sub waitMotion

while Ax.IsMoving

Sleep 1

end while

end sub