Difference between revisions of "Axis Setup Procedure"

m (→Step 4: Position Units Definition) |

m (→Step 4: Position Units Definition) |

||

| Line 73: | Line 73: | ||

==Step 4: Position Units Definition== | ==Step 4: Position Units Definition== | ||

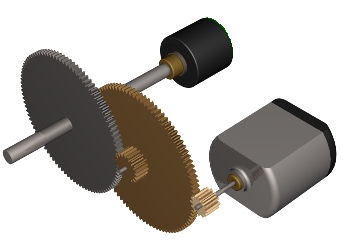

| − | [[Image:GearMotor.png| | + | [[Image:GearMotor.png|GearMotor.png]] |

[[MC-Basic:axis.POSITIONFACTOR|<axis>.PositionFactor]] defines the position units that will be used in all position variables of the specified axis (pcmd, pfb, etc.). It consists of: | [[MC-Basic:axis.POSITIONFACTOR|<axis>.PositionFactor]] defines the position units that will be used in all position variables of the specified axis (pcmd, pfb, etc.). It consists of: | ||

Revision as of 13:25, 17 August 2014

Contents

- 1 Introduction

- 2 Step 1: Declare Axis

- 3 Step 2: Setting Meaningful Axis Name

- 4 Step 3: Preparing General Axis Setup

- 5 Step 4: Position Units Definition

- 6 Step#5: Moving Direction

- 7 Step#6: Velocity, Acceleration, Jerk units

- 8 Step#7:Units summary

- 9 Step#8:Position Limits

- 10 Step#9: Motion Bus Units Setup

- 11 Step#10: Motion Parameters

- 12 Step#11: Safety Parameters

- 13 Step#11: Smoothness

- 14 Step#12: Axis Setup Complete Example - the SetAxis subroutine

- 15 Step#13: Motion-Bus EtherCat example

- 16 Step#14: Extra - Dynamic model

Introduction

This series of slides will explain how to create and set an axis in the softMC controller. For that you will need:

- Running softMC (either a real, or virtual)

- User interface (Control.Studio)

Step 1: Declare Axis

In the first line of CONFIG.PRG file write the number of axes that will be in use:

Sys.Naxes = <number> … Program … End Program

Send this file to MC and run it by issuing these two lines from terminal window:

send config.prg reset all

Now you have your axes defined, it is easily to check issuing this command from terminal window:

->?axislist A1,A2,A3,A4,A5,A6,A7,A8,A9,A10,A11,A12,A13,A14,A15,A16,A17

Step 2: Setting Meaningful Axis Name

System default axis names are not very user friendly (a1,a2,a3, etc.). It is a good practice to give them more meaningful names. This is done in CONFIG.PRG file only, by assigning a new name to each axis (no double-quotes) to <axis>.AxisName property.

Sys.Naxes = <number> … Program a1.AxisName = Xaxis a2.AxisName = Lift … End Program

Step 3: Preparing General Axis Setup

To set up system axes, a setup program must be prepared. Let’s call it SETUP.PRG.</br> It is important to know:

- To access (write to) an axis property, the axis needs to be attached.

- For some properties, the axis needs to be disabled

SETUP.PRG

Program Call SetAxis(a1) Call SetAxis(a2) … End Program Sub SetAxis(ax as generic axis) With ax Attach En = 0 … <stuff goes here> … Detach End With End Sub

Step 4: Position Units Definition

<axis>.PositionFactor defines the position units that will be used in all position variables of the specified axis (pcmd, pfb, etc.). It consists of:

- Motor encoder resolution seen through the motion-bus (See EtherCAT, SERCOS, CanOPEN). How many counts are there in one motor revolution - stored in pos_units global variable (for each axis differently).

- Gear ratio (M:N) and/or the pitch of the linear screw (mm/rev).

- Rotary axes:

- For position in degrees PositionFactor is:PFAC = Pos_Units *(M/N)/360

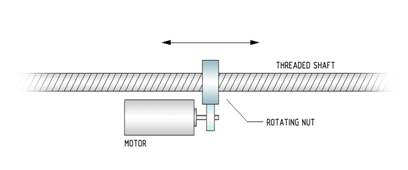

- Linear axes:

- For position in milli-meters PositionFactor is:PFAC = Pos_Units)/MPITCH

See Motion Bus setup for pos_units and MPITCH setup

Step#5: Moving Direction

Positive direction of drive's position increments does not have to match the desired positive direction of user axis (Upwards, Left-Right, Counterclockwise). Therefore <axis>.direction flag is to be used:

<axis>.Direction = {1|-1}

Value of -1 indicates direction inversion.

Step#6: Velocity, Acceleration, Jerk units

Velocity units do not have to match position units (same for acceleration, jerk). User is free to select his/hers own units. For all the derivative units (velocity, acceleration, jerk) the default time scale is in milli-seconds, therefore scaling is needed.

To use position units per second for velocity one needs to define:

<axis>.VelocityFactor = <axis>.PositionFactor/1000

In this case if the user set the position in mm the velocity will be in mm/sec

To define velocity in RPM of the motor:

<axis>.VelocityFactor = Pos_Units /1000/60

For acceleration and jerk units is the same, their default values are expressed in velocity and acceleration units per milli-seconds. So in order to set them per seconds one needs to set them as:

<axis>.AccelerationFactor = <axis>. VelocityFactor /1000

<axis>.JerkFactor = <axis>. AccelerationFactor /1000

Step#7:Units summary

Position, velocity, acceleration and jerk units are set by:

<axis>.PositionFactor = … <axis>.Direction = … <axis>.VelocityFactor = .. <axis>.AccelerationFactor = .. <axis>.JerkFactor = …

Step#8:Position Limits

Setting position range of an axis. Setting max position:

<axis>.Pmax = … and enabling /disabling it: <axis>.PmaxEn = {0|1}

Setting min position:

<axis>.Pmin = … and enabling /disabling it: <axis>.PminEn = {0|1}

Setting the axis type:

<axis>.AxisType = 0 ‘ For linear axes <axis>.AxisType = 1 ‘ For rotary axes

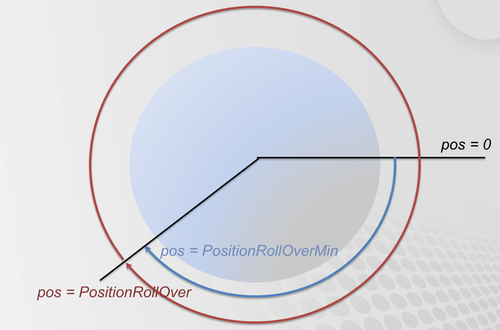

For rotary axes rollover can be defined: Enabling/Disabling it:

<axis>.PositionRollOverEnable = {0|1}

Setting the whole range:

<axis>. PositionRollOver

Setting the low value:

<axis>. PositionRollOverMin

Not that if the enable flag is not set the correspondent value does not need to be set.

Step#9: Motion Bus Units Setup

Depending on the type of Motion-Bus (EtherCAT, SERCOS, CanOpen) and drive used there are several parameters available for the user to be adjusted (not necessarily needed):

In case micro-interpolation is turned on in the drive, the velocity sent to drive must be properly scaled, this is done with (for counts per ms):

<axis>.MotionBusVelocityScale = 0 <axis>.MotionBusVelocityBase = 1

In case a limited drive’s position range is used (other then integer 32 bits):

<axis>.CountMin = < drive min position value> <axis>.CountMax = < drive max position value>

Step#10: Motion Parameters

Motion parameters are grouped into velocity, acceleration and jerk values. They all have their max values for overall limitations, and their motion-default values that are used when motion is executed.

| Motion default value is: | <axis>.VelocityCruise |

Velocity is set according to maximum axis physical limit (drives/motor capabilities and mechanical limitations):

<axis>.Vmax

| Motion default values are: | <axis>.Acceleration <axis>.Deceleration |

Acceleration is set according to maximum axis physical limits (Max drive/motor current, axis load) in user units:

<axis>.Amax <axis>.Dmax

| Motion default value is: | <axis>.Jerk |

Jerk is the third time-derivation of position, if smooth profiles are used it needs to be defined a good rule of thumb is to set J=BW*A, where J – jerk, A – acceleration, BW- control Bandwidth (Hz).

<axis>.JerkMax

Step#11: Safety Parameters

Maximum allowed position error (PE). PE is defined as a difference between the position command and position feedback. Due to communication delay of the motion bus and processing time of the drive (micro-interpolation) position command of the several samples before the current is compared to the currently obtained position feedback of the drive:

<axis>.PositionErrorMax – max allowed position error during in user units. <axis>.PositionErrorDelay – number of samples used for delay computation.

Velocity (Runaway) Protection, the feedback velocity of the motor is checked every sample (recommended to be set to 120% of the <axis>.VelocityMax)

<axis>.VelocityOverSpeed

Sanity Threshold, as a final protection against unintentional jumps (recommended to be set to 1000% of <axis>.VelocityMax):

<axis>.VelocitySafetyLimit

Torque Error – only if axis dynamic model is turned on

<axis>.TorqueMaxError

Step#11: Smoothness

Different profile types are available from very smooth S-curves (Acceleration Trapeze, Sine Acceleration) to less smooth by faster Velocity Trapeze, to totally edgy profiles (Constant Velocity) by setting these two parameters:

<axis>.Smooth defined automatic (0-100) or manual smoothing (-1) <axis>.PrfType specifies profile more precisely (Velocity Trapeze, Acceleration Trapeze, Sine Acceleration)

Step#12: Axis Setup Complete Example - the SetAxis subroutine

sub SetRotAxis(ax as generic axis, byval minval as double , byval maxval as double)

with ax

attach

En = 0

AxisType = 1

PositionFactor = pos_unit/360

VelocityFactor = PositionFactor /1000

AccelerationFactor = VelocityFactor /1000

Jerkfactor = AccelerationFactor /1000

VelocityMax = 1000

AccelerationMax = 10000

DecelerationMax= 10000

JerkMax = 20*amax

VelocityCruise = 0.5*VelocityMax

Acceleration = AccelerationMax

Deceleration = DecelerationMax

Jerk = JerkMax

PrfType = -1

Smooth = -1

VelocityOverspeed = 1.2*VelocityMax

VelocitySafetyLimit = 10*VelocityMax

PositionErrorDelay = 2

PositionErrorMax = 1

PositionMax = maxval

PositionMin = minval

PositionMaxEn = 1

PositionMinEn = 1

PositionRolloverEnable = 0

detach

end with

end sub

Step#13: Motion-Bus EtherCat example

Position Units

- First read the motor encoder resolution (MENCRES – SDO:0x20F1:0)

- MENCRES = EC_SDO_READ(<addr>,0x20f1,0)

Then set (value of 1) the configured number of motor shaft revolutions and number of driving shaft revolutions. The gear ratio is calculated by the following:

- Fieldbus CANopen Gear Motor Shaft Scaling (FBGMS – SDO0x2091:0)

- Fieldbus CANopen Gear Driving Shaft Scaling (FBGDS – SDO0x2091:1)

- gear ratio = FBGMS / FBGDS

Step#14: Extra - Dynamic model

Torque Scaling

- <axis>.TorqueFactor – according to the Motor KT parameter

Limits

- <axis>.TorqueMax – maximum motor torque

Dynamic Model Parameters

- axis.DYNAMICMODEL[..] = <…>