Difference between revisions of "Flying Shear Application/zh-hans"

(Created page with "{{Languages}} = Introduction = The task of a flying shear application is to cut a constantly moving material to a predefined length. Unlike the punch-cutting, the cutting is d...") |

|||

| (One intermediate revision by the same user not shown) | |||

| Line 1: | Line 1: | ||

| − | {{Languages}} | + | {{Languages|Flying_Shear_Application}} |

| − | = | + | = 简介 = |

| − | + | 飞剪应用的任务是将不断移动的材料切割成预定长度。与冲切不同,切割是在运动中完成的。在飞剪应用中,运动任务必须在主轴和从轴之间保持同步一段时间,然后尽可能快地返回到初始位置,以准备下一次切割。可以可选添加用于长度校正的传感器。虽然这是作为切割应用程序呈现的,但该示例可用于其他应用程序,例如在产品上贴标签或打印标记。应用程序设置在达到同步点时的输出。 该输出可以启动切割机构,但可以启动任何其他打印或贴标签设备。 | |

| − | = | + | |

| + | =应用图 = | ||

[[File:flyshr1.png]] | [[File:flyshr1.png]] | ||

| − | + | 飞剪应用的近似运动曲线如下所示: | |

| − | = | + | = 运动曲线 = |

[[File:flyshr2.png]] | [[File:flyshr2.png]] | ||

| − | + | 运动分为三个阶段。第一阶段包括停车时间。到同步点的滑架加速度是滑架应该与主轴的切割长度同步的阶段。第二阶段或切割由切割过程完成所需的时间决定。第三个也是最后一个阶段是滑架回零位置。 | |

| − | + | 我们假设材料流速是恒定的,已知:Vm。 此外,我们假设加速度和减速度值都相同。 要获取凸轮轮廓参数,请使用以下公式: | |

[[File:flyshr3.png]] | [[File:flyshr3.png]] | ||

| − | + | 这里,已知的是L,T和A.所请求的是分析器参数tacc,tdec,v。使用上述等式,用于飞剪应用的代码如下(使用从Cut To Length示例的VTProfile和ProfileLTA例程): | |

| − | = | + | = 程序 = |

<syntaxhighlight lang="vb"> | <syntaxhighlight lang="vb"> | ||

| Line 196: | Line 197: | ||

</syntaxhighlight> | </syntaxhighlight> | ||

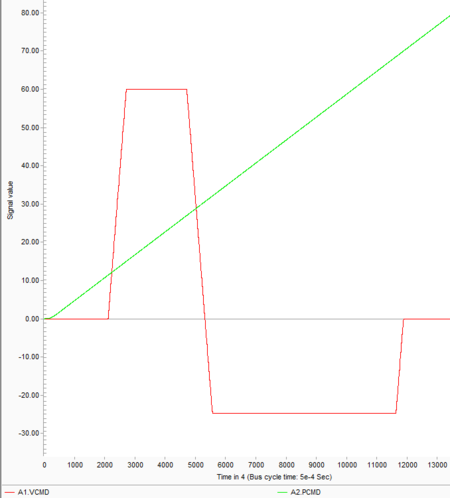

| − | = | + | = 记录曲线 = |

[[File:flyshr4.png|450px]] | [[File:flyshr4.png|450px]] | ||

Latest revision as of 02:35, 17 July 2017

| 语言: | English • 中文(简体) |

|---|

简介

飞剪应用的任务是将不断移动的材料切割成预定长度。与冲切不同,切割是在运动中完成的。在飞剪应用中,运动任务必须在主轴和从轴之间保持同步一段时间,然后尽可能快地返回到初始位置,以准备下一次切割。可以可选添加用于长度校正的传感器。虽然这是作为切割应用程序呈现的,但该示例可用于其他应用程序,例如在产品上贴标签或打印标记。应用程序设置在达到同步点时的输出。 该输出可以启动切割机构,但可以启动任何其他打印或贴标签设备。

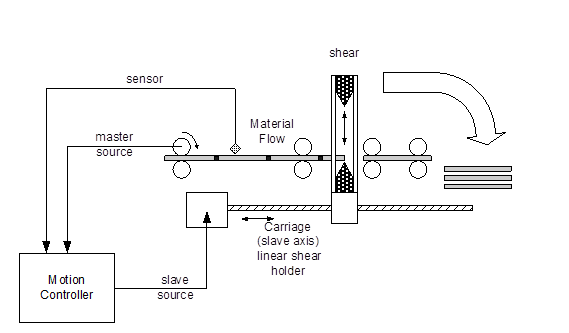

应用图

飞剪应用的近似运动曲线如下所示:

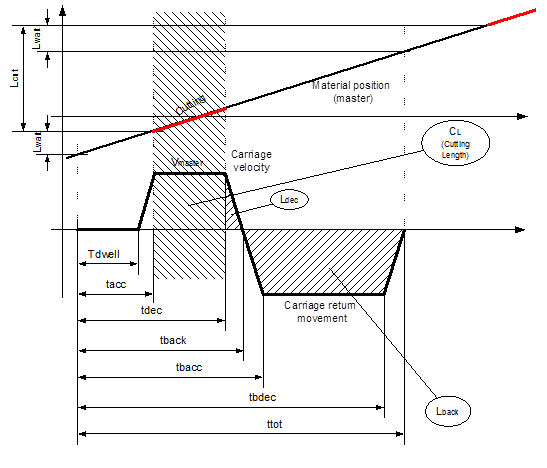

运动曲线

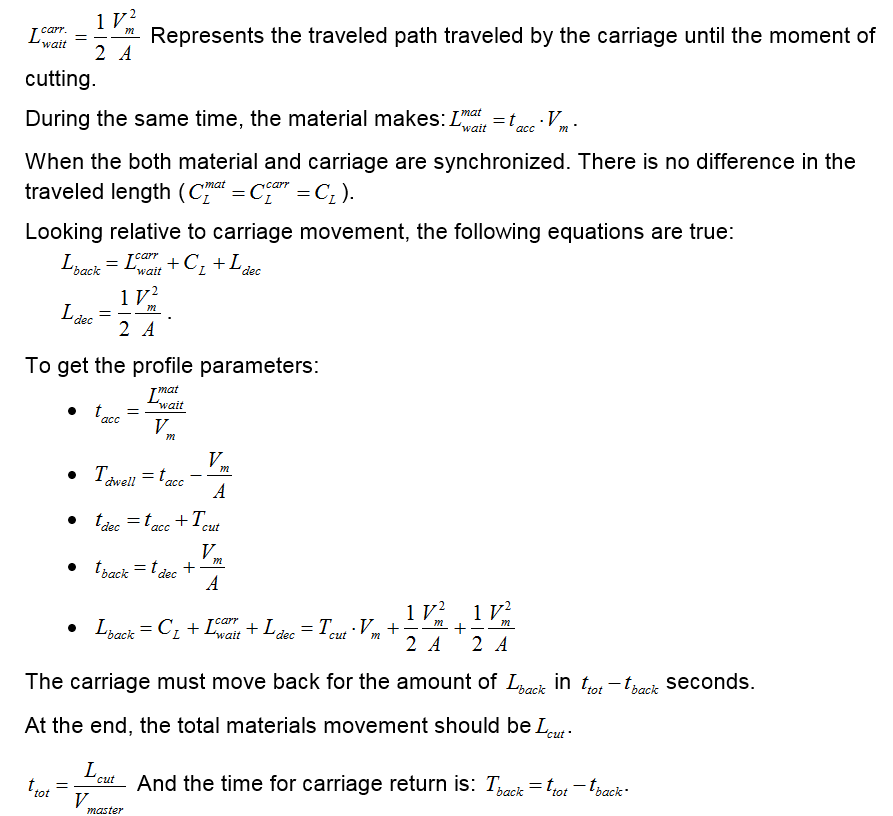

运动分为三个阶段。第一阶段包括停车时间。到同步点的滑架加速度是滑架应该与主轴的切割长度同步的阶段。第二阶段或切割由切割过程完成所需的时间决定。第三个也是最后一个阶段是滑架回零位置。 我们假设材料流速是恒定的,已知:Vm。 此外,我们假设加速度和减速度值都相同。 要获取凸轮轮廓参数,请使用以下公式:

这里,已知的是L,T和A.所请求的是分析器参数tacc,tdec,v。使用上述等式,用于飞剪应用的代码如下(使用从Cut To Length示例的VTProfile和ProfileLTA例程):

程序

common shared c1 as cam

dim shared toolong as error "The given cut length is too long for the given slave accel."

dim shared toofast as error "Slave axis can not move that fast"

dim shared tooshortw as error "Waiting period too short"

' Shared profile parameters:..............................................

dim shared lprof as double ' total legth

dim shared aprof as double ' acceleration used

dim shared vprof as double ' cruise velocity

dim shared t_acc_prof as double ' acceleration duration

dim shared t_dec_prof as double ' end of cruise phase

dim shared t_tot_prof as double ' total velocity trapeze duration

'.........................................................................

program

dim i as long

' Process data

dim Vmaster as double

dim CutLength as double

dim CutTime as double

dim DwellTime as double

dim BackLength as double

dim WaitLengthMaster as double

dim WaitLengthSlave as double

dim DecLength as double

dim CutPath as double

' Cam profile parameters

dim t_acc as double

dim t_dec as double

dim t_back as double

dim t_tot as double

dim vback as double

' Variables used in cam computation

dim t as double

dim dt as double

WaitLengthMaster = 15 ' Length in mm that is passed before the carriage is synchronized

Vmaster = 60 ' mm/sec - velocity of the material

CutLength = 70 ' mm of the master material feed

CutTime = 0.2 ' Time 200 ms needed for the cut

with A1 'A1 = Carriage (Slave)

Attach

Slave=0

FirstCam = none

CreateCamData 1000 c1 ' Creating 1000 points in the cam

CutPath = Vmaster*CutTime ' Path traveled during cutting process

t_acc = WaitLengthMaster/Vmaster ' end of acceleration

DwellTime = t_acc - Vmaster/acc ' dwell duration

if DwellTime < 0 then

throw tooshortw

end if

t_dec = t_acc + CutTime ' Time to start deceleration.

t_back = t_dec + Vmaster/acc ' Time to starts carriage return

t_tot = CutLength/Vmaster ' Total time of the movement is

WaitLengthSlave = 0.5*Vmaster^2/acc ' Path passed by slave during waiting

DecLength = 0.5*Vmaster^2/acc ' Path passed by slave during deceleration

BackLength = CutPath + WaitLengthSlave + DecLength ' Total movement length

' Setting for the first trapeze (forward carriage motion)

lprof = CutPath + WaitLengthSlave + DecLength

aprof = acc

vprof = Vmaster

t_acc_prof = t_acc - DwellTime

t_dec_prof = t_dec - DwellTime

t_tot_prof = t_back - DwellTime

dt = t_tot/(c1.size-1)

t = 0

while t <= t_back

i = round(t/dt) +1

c1.MasterData[i] = t*Vmaster

if t < DwellTime then

c1.SlaveData[i] = 0

else

c1.SlaveData[i] = VTProfile(t-DwellTime)

end if

t = t + dt

end while

' Next trapeze (carriage return)

lprof = CutPath + WaitLengthSlave + DecLength

call ProfileLTA(lprof ,t_tot - t_back, acc)

while t <= t_tot

i = round(t/dt) +1

c1.MasterData[i] = t*Vmaster

c1.SlaveData[i] = BackLength - VTProfile(t-t_back)

t = t + dt

end while

c1.MasterData[c1.size] = CutLength

c1.SlaveData[c1.size] = 0

' Setup the camming

c1.Cycle = -1 ' endless camming

FirstCam = c1

MasterSource = A2.Pcmd

GearRatio = 1

Slave = cam

En = ON

Detach A1

end with

Print "Flying Shear Ready"

end program

'.................................................................................

' Velocity Trapeze gernal purpose profile function

' uses shared variables:

' t_acc - time where acceleration ends (cruise starts)

' t_dec - time where deceleration starts (cruise ends)

' t_tot - end of movement

' aprof - accleration/deceleration value

' vprof - cruise (max) velocity

' lprof - total movement length

function VTProfile(byval t as double) as double

select case(t)

case is <=0

VTProfile = 0

case is <= t_acc_prof

VTProfile = 0.5*aprof*t^2

case is <= t_dec_prof

VTProfile = 0.5*vprof^2/aprof + (t-t_acc_prof)*vprof

case is < t_tot_prof

VTProfile = lprof - 0.5*aprof*(t_tot_prof-t)^2

case else

VTProfile = lprof

end select

end function

' Velocity Trapeze pre-calculation routine

' Input: Length, Total time, max Accleration

' Global used: Vmax

sub ProfileLTA(byval L as double ,byval T as double, byval A as double)

dim sqr as double

with A1

aprof = A

sqr = T^2 - 4*L/A

select case (sqr)

case is < -0.004 ' less then 4ms

throw toolong

case is < 0

' In cases of numeric computation errors (high accel. values) this could be a small

' negative number. In order to avoid math error the value is cut to zero.

sqr = 0

case else

sqr = sqrt(sqr)

end select

vprof = 0.5*A*(T - sqr)

if vprof > vmax then

throw toofast

end if

' Compute fixed points in time (end of acceleration, begin of deceleration)

t_acc_prof = vprof/A

t_dec_prof = T - t_acc_prof

t_tot_prof = T

end with

end sub