Difference between revisions of "Cut To Length (Punching) Application"

| (One intermediate revision by the same user not shown) | |||

| Line 1: | Line 1: | ||

| − | {{Languages}} | + | {{Languages|Cut_To_Length_(Punching)_Application}} |

| − | = | + | = Introduction = |

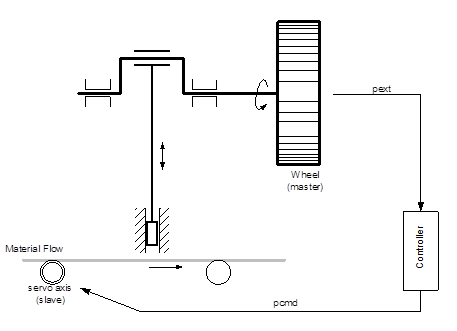

| − | + | An eccentric press (crank press) is being feed by a servo-driven feeding device cammed to the angular position of the wheel. The wheel position is measured by an external feedback device (resolver, encoder, etc.) that is connected to a drive as an external position signal (PEXT). | |

| − | = | + | = Application Diagram = |

[[File:cut2len1.png]] | [[File:cut2len1.png]] | ||

| − | + | The angular position of the wheel is the master source signal that continuously increases during its operation. On each turn of the wheel, there is a start and end angle value where the feed axis should stop. | |

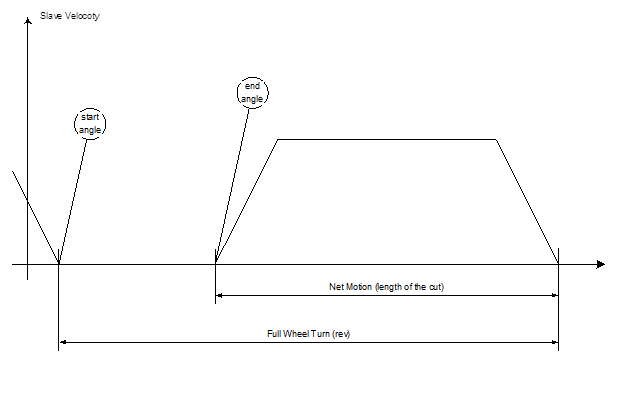

| − | = | + | = Motion profile = |

| − | + | The feed axis operation looks like: | |

[[File:cut2len2.png]] | [[File:cut2len2.png]] | ||

| − | + | The main task in building this application is to design a cam according to the following parameters: | |

| − | • | + | • Total wheel turn angle, value of pext needed for one full turn of the wheel. |

| − | • | + | • Start angle, wheel angle where the punching starts |

| − | • | + | • End angle, wheel angle where the material can be moved or when the punching ends. |

| − | • | + | • Length of the cut, the distance of slave position between the last end-angle to the next start-angle of the wheel. |

| − | • | + | • Maximum acceleration and velocity of the slave axis, these values can not be exceeded during camming. |

| − | + | An additional limitation is the decision to take velocity trapezoidal profile for the slave motion. Another profile could be taken, but the equations would differ. | |

| − | + | The wheel velocity is assumed to be constant and known for the computations. Now, to compute a motion profile from the given A, L, T values, see Appendix at end of example. | |

| − | = | + | = Program = |

<syntaxhighlight lang="vb"> | <syntaxhighlight lang="vb"> | ||

common shared c1 as cam | common shared c1 as cam | ||

| Line 171: | Line 171: | ||

''' | ''' | ||

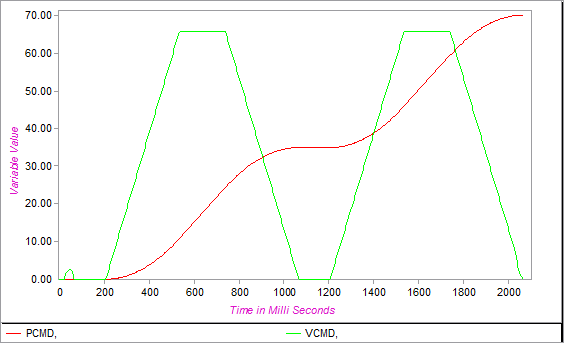

| − | = | + | = Profile recording = |

| − | + | Two turns of the master wheel (cut length 20 mm): | |

[[File:cut2len4.PNG]] | [[File:cut2len4.PNG]] | ||

| − | + | A 35 mm length close to triangular profile: | |

[[File:cut2len5.png]] | [[File:cut2len5.png]] | ||

| − | = | + | = Computing velocity profile with known A, L, T = |

[[File:cut2len3.PNG]] | [[File:cut2len3.PNG]] | ||

Latest revision as of 15:36, 27 November 2017

| Language: | English • 中文(简体) |

|---|

Contents

Introduction

An eccentric press (crank press) is being feed by a servo-driven feeding device cammed to the angular position of the wheel. The wheel position is measured by an external feedback device (resolver, encoder, etc.) that is connected to a drive as an external position signal (PEXT).

Application Diagram

The angular position of the wheel is the master source signal that continuously increases during its operation. On each turn of the wheel, there is a start and end angle value where the feed axis should stop.

Motion profile

The feed axis operation looks like:

The main task in building this application is to design a cam according to the following parameters: • Total wheel turn angle, value of pext needed for one full turn of the wheel. • Start angle, wheel angle where the punching starts • End angle, wheel angle where the material can be moved or when the punching ends. • Length of the cut, the distance of slave position between the last end-angle to the next start-angle of the wheel. • Maximum acceleration and velocity of the slave axis, these values can not be exceeded during camming. An additional limitation is the decision to take velocity trapezoidal profile for the slave motion. Another profile could be taken, but the equations would differ. The wheel velocity is assumed to be constant and known for the computations. Now, to compute a motion profile from the given A, L, T values, see Appendix at end of example.

Program

common shared c1 as cam

dim shared toolong as error "The given cut length is too long for the given slave accel."

dim shared toofast as error "Slave axis can not move that fast"

' Shared profile parameters:..............................................

dim shared lprof as double ' total length

dim shared aprof as double ' acceleration used

dim shared vprof as double ' cruise velocity

dim shared t_acc_prof as double ' acceleration duration

dim shared t_dec_prof as double ' end of cruise phase

dim shared t_tot_prof as double ' total velocity trapeze duration

'.........................................................................

program

' Process data

dim sangle as double = 10 ' start to cut at this angle

dim eangle as double = 60 ' finish the cut at this angle

dim rev as double = 360 ' full turn of the wheel

dim Vwheel as double = 60 ' RPM - velocity of the wheel

dim CutLength as double = 20 ' mm of the slave motion

dim CutAngle as double

dim CutTime as double

dim i as long

' Variables used in cam computation

dim t as double

dim t_from_end as double

' Creating 1000 points in the cam

createcamdata 1000 c1

' Computing the next motion

CutAngle = rev - (eangle-sangle) ' The wheel passes this angel while it moves

CutTime = CutAngle/(Vwheel*360/60) ' Time needed to move to another cut (sec)

with A1

call ProfileLTA(CutLength,CutTime,Acc)

' Start computing the cam table

' t is relative time of velocity trapeze profile

for i = 1 to c1.size

c1.MasterData[i] = (i-1)*rev/c1.size ' Defining a uniform master axis

select case (c1.MasterData[i])

case is < sangle ' it is a rotary axis in cases when master < start

' we need to compute the relative time from the end

t_from_end = (sangle - c1.MasterData[i])/(Vwheel*360/60)

t = CutTime - t_from_end

c1.SlaveData[i] = VTProfile(t) - CutLength

case is <= eangle ' master is between start and end - no motion of slave:

c1.SlaveData[i] = 0.0

case is > eangle ' Time passed after exit [start,end] master segment

t = (c1.MasterData[i]-eangle)/(Vwheel*360/60)

c1.SlaveData[i] = VTProfile(t)

end select

next

end with

with A2

' Setup the cam table

c1.Cycle = -1 ' endless camming

Attach

FirstCam = c1

MasterSource = A1.Pcmd 'For example with 2 axes

' MasterSource = pext

GearRatio = 1

Slave = CAM

SlaveDisconnect = 0

En = ON

Detach

end with

Print "Cut to length Ready"

end program

' Velocity Trapeze pre-calculation routine

' Input: Length, Total time, max Accleration

' Global used: Vmax

sub ProfileLTA(byval L as double ,byval T as double, byval A as double)

dim sqr as double

with A1

aprof = A

sqr = T^2 - 4*L/A

select case (sqr)

case is < -0.004 ' less then 4ms

throw toolong

case is < 0

' In cases of numeric computation errors (high accel. values) this could be a small

' negative number. In order to avoid math error the value is cut to zero.

sqr = 0

case else

sqr = sqrt(sqr)

end select

vprof = 0.5*A*(T - sqr)

if vprof > vmax then

throw toofast

end if

' Compute fixed points in time (end of acceleration, begin of deceleration)

t_acc_prof = vprof/A

t_dec_prof = T - t_acc_prof

t_tot_prof = T

end with

end sub

'.................................................................................

' Velocity Trapeze gernal purpose profile function

' uses shared variables:

' t_acc - time where acceleration ends (cruise starts)

' t_dec - time where deceleration starts (cruise ends)

' t_tot - end of movement

' aprof - accleration/deceleration value

' vprof - cruise (max) velocity

' lprof - total movement length

function VTProfile(byval t as double) as double

select case(t)

case is <=0

VTProfile = 0

case is <= t_acc_prof

VTProfile = 0.5*aprof*t^2

case is <= t_dec_prof

VTProfile = 0.5*vprof^2/aprof + (t-t_acc_prof)*vprof

case is < t_tot_prof

VTProfile = lprof - 0.5*aprof*(t_tot_prof-t)^2

case else

VTProfile = lprof

end select

end function

Profile recording

Two turns of the master wheel (cut length 20 mm):

A 35 mm length close to triangular profile: